Preparation method of hydrothermal carbon modified asphalt

A technology for modifying asphalt and hydrothermal carbon, which is used in construction, building components, building insulation materials, etc., can solve the problems of poor dispersibility and poor modification effect of hydrothermal carbon materials, improve road performance and reduce damage. , the effect of strengthening the internal cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

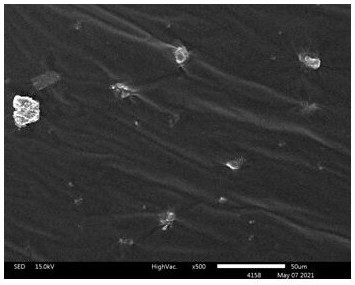

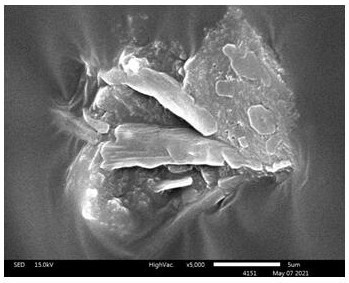

[0029] Embodiment 1: The preparation method of the hydrothermal carbon modified asphalt of the present embodiment is carried out according to the following steps:

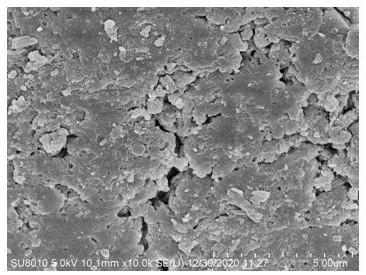

[0030] 1. Using waste corn stalks as carbon source, hydrothermal carbonization is adopted. The specific hydrothermal carbonization operation is as follows: after pulverizing the waste corn stalks, put them into a hydrothermal reaction kettle, and then add corn stalk powder with a mass of 15 times the mass of plasma water, seal the hydrothermal reaction kettle, put the reaction kettle into the heating furnace, heat it up to 250 ° C and keep it for 3 hours, after the hydrothermal reaction kettle is cooled to room temperature, filter the reaction product with filter paper and separate, Finally, the obtained solid product was placed in an oven with a temperature of 80° C. for 12 hours to obtain agglomerated and granular hydrothermal carbon;

[0031] 2. Immerse the hydrothermal carbon in liquid nitrogen for 3 minutes; ...

Embodiment 2

[0042] Embodiment 2: The preparation method of the hydrothermal carbon modified asphalt of the present embodiment is carried out according to the following steps:

[0043] 1. Using waste wood as carbon source, the hydrothermal carbon method is used for carbonization; the specific hydrothermal carbonization operation is: pulverize the waste wood into powder, put it into the hydrothermal reaction kettle, and then add 20 times the mass of wood powder. After the hydrothermal reactor was cooled to room temperature, filter paper was used to filter and separate the reaction product, and finally the obtained solid product was placed at a temperature of 100 °C. Keep in the oven for 12 hours to obtain agglomerated and granular hydrothermal charcoal;

[0044] 2. Immerse the hydrothermal carbon in liquid nitrogen for 5 minutes;

[0045] 3. Add the hydrothermal carbon treated with liquid nitrogen to the grinder for grinding, and analyze the particle size of the ground hydrothermal carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com