Preparation method of grain boundary diffused heavy rare earth NdFeB magnet and NdFeB magnet

A grain boundary diffusion, NdFeB technology, applied in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of small coercivity improvement of NdFeB magnet materials, poor effect of heavy rare earth elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

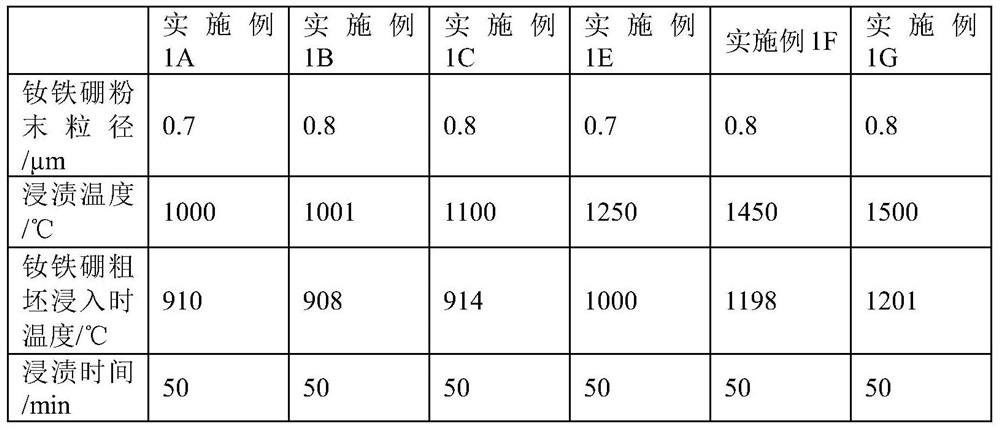

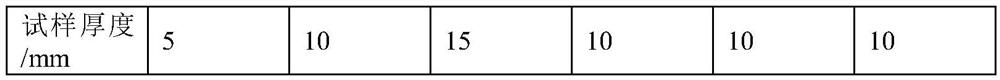

Embodiment 1

[0049] A method for preparing a grain boundary diffused heavy rare earth NdFeB magnet, comprising the following steps:

[0050] S1: NdFeB powder with a particle size of 2.0-2.5 μm is obtained by distributing ingredients according to the design, casting and smelting, hydrogen crushing, and jet milling;

[0051] S2: The NdFeB powder is subjected to oriented static pressure molding on the mixture in a 1.5T magnetic field to obtain a rough NdFeB blank with gaps or pores;

[0052] S3: Mix the material containing heavy rare earth elements with NdFeB powder and heat it to the immersion temperature and keep it in a molten state. The immersion temperature is 1100±5°C to obtain a heavy rare earth source melt;

[0053] S4: Put the NdFeB rough blank in a cage or basket and move it above the liquid level of the heavy rare earth source melt, and heat the NdFeB rough blank;

[0054] S5: When the NdFeB rough billet is heated to a temperature lower than the dipping temperature of 85-95°C or 1...

Embodiment 2

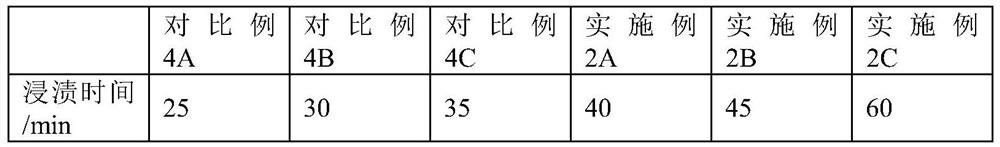

[0093] A method for preparing a grain boundary diffused heavy rare earth NdFeB magnet. On the basis of Example 1F, Example 2A-2C is set. The difference between Example 2A-2C and Example 1F is that the immersion time is different, and the immersion time is different. Less than 40min.

Embodiment 3

[0101] A method for preparing a grain boundary diffused heavy rare earth NdFeB magnet, based on the first embodiment, the difference is that the NdFeB powder in S2 is mixed with a binder and then oriented static pressure molding, the binder The mass ratio of NdFeB powder to NdFeB powder is 0.02-0.03:1, and the binder is a low molecular weight carbon chain polymer. At the same time, the oriented static pressure forming and compaction in S2 obtains the NdFeB rough billet;

[0102] The finished NdFeB magnet is a disc with a diameter of 25mm and a thickness of 10mm. The element composition of finished NdFeB magnets is as follows:

[0103] PrNd: 19-20wt%, Ce: 2.2-2.3wt%, Y: 2.4-2.5wt%, Dy: 0.8-0.9wt%, B: 0.80-0.96wt%, Al: 0.3-0.4wt%, Co: 0.8 -1.1wt%, Zr: 0.10-0.12wt%, Cu: 0.10-0.18wt%, the rest is iron and unavoidable impurities.

[0104] The grain boundary diffused heavy rare earth NdFeB magnets with different thicknesses were prepared according to the above preparation method,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com