Wear-resistant high-strength shoe material and preparation method thereof

A high-strength, shoe material technology, applied in the field of wear-resistant shoe materials, can solve problems such as insufficient wear resistance of soles, and achieve the effects of enhancing bonding force, increasing polarity, and improving interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

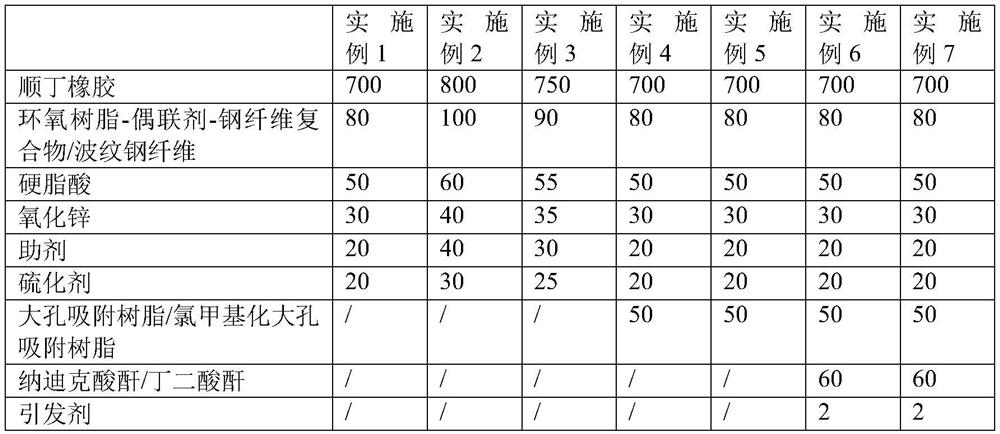

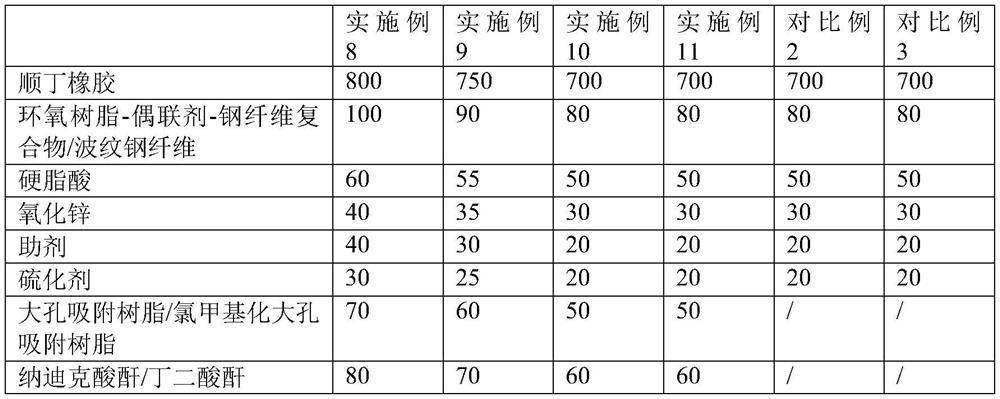

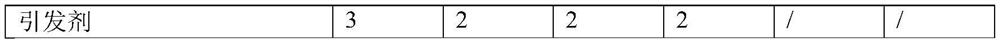

Examples

preparation example 1

[0041] Preparation of epoxy resin-coupling agent-steel fiber composite: add 10g of coupling agent to 80g of 10% (v / v) ethanol aqueous solution and mix well, adjust pH to 4.0 with acetic acid, continue stirring for 10min, then add 80g Corrugated steel fiber and stirred, kept at 70°C for 30 minutes in a water bath, filtered to remove the filtrate, dried and dehydrated the filter residue in an oven at 80°C for 2 hours, cooled to room temperature, beat to break up, then added 20g of epoxy resin and stirred for 30 minutes to obtain a ring Oxygen resin-coupling agent-steel fiber composite.

[0042] Wherein, the coupling agent is vinyltrimethoxysilane.

preparation example 2

[0044]Preparation of epoxy resin-coupling agent-steel fiber composite: add 20g of coupling agent to 120g of 10% (v / v) ethanol aqueous solution and mix well, adjust pH to 4.0 with acetic acid, continue stirring for 15min, then add 100g Corrugated steel fiber and stirred, kept at 80°C for 20min in a water bath, filtered to remove the filtrate, dried and dehydrated the filter residue in an oven at 90°C for 1.5h, cooled to room temperature, beat to break up, then added 30g of epoxy resin and stirred for 20min to obtain Epoxy resin-coupling agent-steel fiber composite.

[0045] Wherein, the coupling agent is vinyltrimethoxysilane.

preparation example 3

[0047] Preparation of epoxy resin-coupling agent-steel fiber composite: add 15g of coupling agent to 100g of 10% (v / v) ethanol aqueous solution and mix well, adjust pH to 4.0 with acetic acid, continue stirring for 13min, then add 90g Corrugated steel fiber and stirred, kept at 75°C for 25 minutes in a water bath, filtered to remove the filtrate, dried and dehydrated the filter residue in an oven at 85°C for 2 hours, cooled to room temperature, beat to break up, then added 25g of epoxy resin and stirred for 25 minutes to obtain a ring Oxygen resin-coupling agent-steel fiber composite.

[0048] Wherein, the coupling agent is vinyltrimethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com