Insulating heat-conducting gasket and preparation method thereof

A technology of insulating heat conduction and gasket, applied in the fields of heat conduction and heat dissipation material, heat conduction interface material and thermal management material, it can solve the problems of unsatisfactory heat conduction performance of gasket, small filling amount, increase filling difficulty, etc., and achieve low cost and high insulation. The effect of high thermal conductivity and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Hereinafter, the preparation method of the insulating and heat-conducting gasket of the present invention will be described, which roughly includes the following steps.

[0063] Step (a): mixing two-dimensional thermally conductive fillers and polymers;

[0064] Step (b): converting the polymer into a filament by high-speed shearing or high-speed centrifugal rotation, and connecting the two-dimensional heat-conducting fillers to each other;

[0065] Step (c): adding an adhesive and fully mixing, so that the polymer filament runs through the entire system to form a network structure;

[0066] Step (d): compressing the mixture into a sheet;

[0067] Step (e): laminating the sheets formed in step (d) and pressing them into a block, and solidifying and forming;

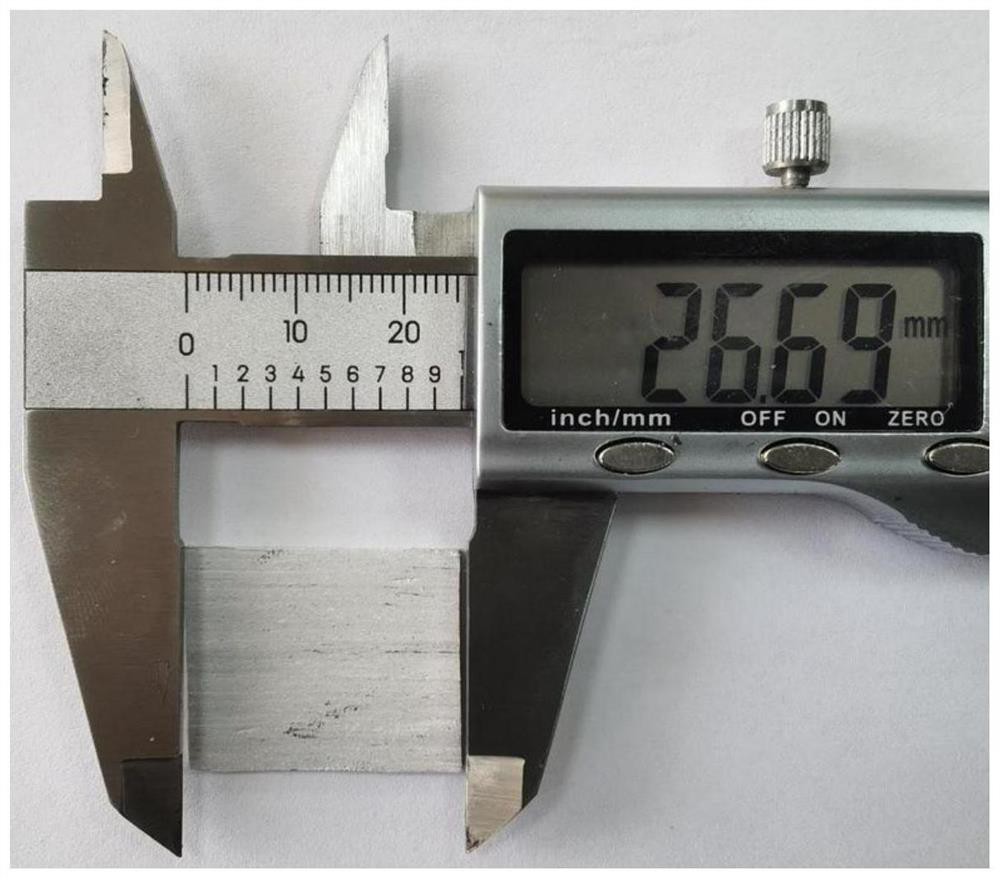

[0068] Step (f): cutting the solidified and formed block in step (e) along the height direction of the laminated sheets to obtain several thin sheets (ie, the insulating and thermally conductive gasket of the pre...

Embodiment 1

[0078] In this embodiment, the two-dimensional sheet-shaped thermally conductive filler is boron nitride, accounting for 50wt%, the high molecular polymer is drawing grade PI, accounting for 5wt%, and the liquid silicone uses polydimethylcyclosiloxane, accounting for 50wt%. 45% by weight. In addition, the size distribution of the boron nitride sheet is in the range of 20-50 μm.

[0079] The high-molecular polymer is drawn to form a filamentary network by high-speed shearing, the shearing rate is 30000r / min, and the shearing time is 1min.

[0080] Subsequently, press to form a sheet with a thickness of 0.2 mm, and then stack several layers of sheets with the same thickness and press to form a block, and the block is cured and formed at a curing temperature of 150°C. Then, along the height direction of the layer-by-layer stacking of the aforementioned sheets, the cured and formed block was cut into several thin slices with a thickness of 1 mm to obtain the insulating and therma...

Embodiment 2

[0083] In this embodiment, the two-dimensional sheet-shaped thermally conductive filler is boron nitride, accounting for 92wt%, the high molecular polymer is drawing grade PE, accounting for 3wt%, and the liquid silicone is polydimethylsiloxane, accounting for 5wt%. . In addition, the diameter of the boron nitride sheet is 50-200 μm.

[0084] The high-molecular polymer is drawn to form a filamentary network by high-speed shearing, the shearing rate is 5000r / min; the shearing time is 15min.

[0085] Subsequently, a sheet with a thickness of 3 mm was prepared, and several layers of sheets with the same thickness were stacked and pressed into a block, and the block was solidified and formed at a curing temperature of 120° C. Then, along the height direction of the aforementioned stacked layers, the cured and formed block was cut into several slices with a thickness of 1 mm to obtain the insulating and thermally conductive gasket sample of Example 2 of the present invention.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com