A kind of preparation method of core-shell type carboxyl benzene ring type emulsion polymer for coating

An emulsion polymer, core-shell type technology, applied in the field of building surface waterproofing and adhesion coatings, building materials, can solve the problems of insufficient comprehensive performance of coatings, etc., to achieve the goals of narrowing the molecular weight distribution range, wide application range, and good film-forming properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

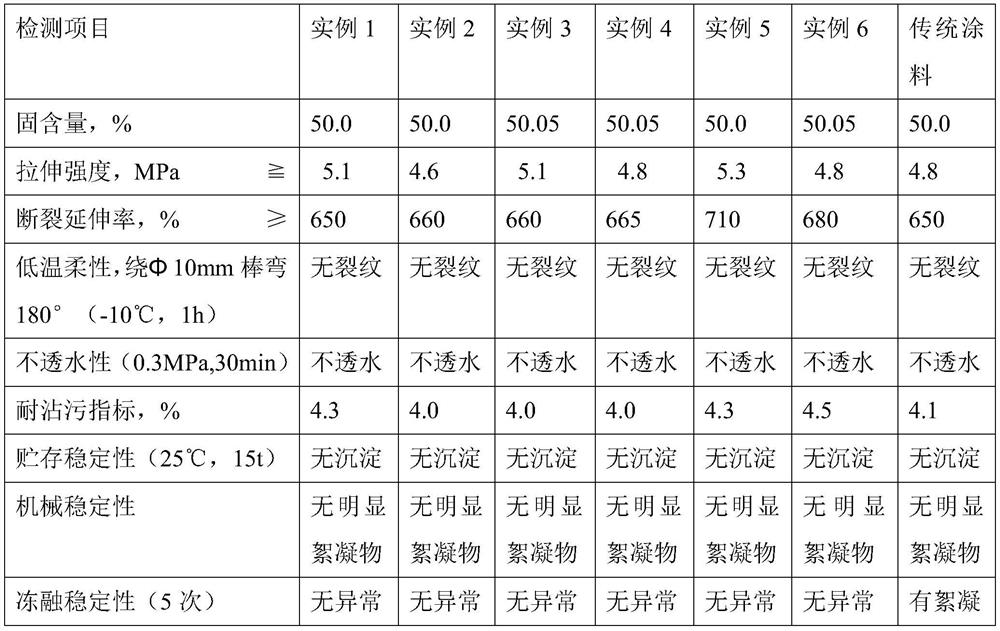

Examples

example 1

[0050] A method for preparing a core-shell type carboxybenzene ring emulsion polymer for coatings. It is formed by polymerizing the following components. The total mass of raw materials is 1000 parts. The components and process parameters are as follows:

[0051] Aconitic acid: 3.0 parts

[0052] 4-methoxy-2-vinylaniline: 14.0 parts

[0053] Dicyclohexyl peroxydicarbonate: 0.25 parts

[0054] Sodium hypophosphite: 0.45 parts

[0055] Fumaric acid: 12 parts

[0056] Ethyl acrylate: 193 parts

[0057] 1-allyl-2-fluorobenzene: 223 parts

[0058] N-(4-vinylbenzyl)-N,N-dimethylamine: 23 parts

[0059] Dicumyl peroxide: 1.5 parts

[0060] Lauryl peroxide: 1.5 parts

[0061] Ascorbic acid: 2 parts

[0062] Di(methacryloyloxyethyl)phthalic anhydride ester: 6.0 parts

[0063] Triisopropanolamine: 2.2

[0064] Potassium hydroxide: 2.8 parts

[0065] Composition of trifluoroethyl acrylate and perfluorooctyl ethyl acrylate with a mass ratio of 1:1: 14 parts

[0066] The remain...

example 2

[0074] A method for preparing a core-shell type carboxybenzene ring emulsion polymer for coatings. It is formed by polymerizing the following components. The total mass of raw materials is 1000 parts. The components and process parameters are as follows:

[0075] Composition of carboxyl hydrophilic monomers itaconic acid and aconitic acid with a mass ratio of 3:1: 3.0 parts

[0076] 4-methoxy-2-vinylaniline: 14.0 parts

[0077] Dicyclohexyl peroxydicarbonate: 0.25 parts

[0078] Sodium hypophosphite: 0.45 parts

[0079] Aconitic acid: 12 parts

[0080] Ethyl acrylate: 192 parts

[0081] Composition of 1-allyl-2-fluorobenzene and 1-phenylvinylboronic acid with a mass ratio of 3:1: 223 parts

[0082] N-(4-vinylbenzyl)-N,N-dimethylamine: 23 parts

[0083] Dicumyl peroxide: 1.5 parts

[0084] Lauryl peroxide: 1.5 parts

[0085] Ascorbic acid: 2 parts

[0086] Di(methacryloyloxyethyl)phthalic anhydride ester: 6.0 parts

[0087] Triisopropanolamine: 2.2

[0088] Potassium ...

example 3

[0097] A method for preparing a core-shell type carboxybenzene ring emulsion polymer for coatings. It is formed by polymerizing the following components. The total mass of raw materials is 1000 parts. The components and process parameters are as follows:

[0098] Composition of carboxyl hydrophilic monomers itaconic acid and aconitic acid with a mass ratio of 3:1: 3.0 parts

[0099] 4-methoxy-2-vinylaniline: 14.0 parts

[0100] Dicyclohexyl peroxydicarbonate: 0.25 parts

[0101] Sodium hypophosphite: 0.45 parts

[0102] Aconitic acid: 12 parts

[0103] Ethyl acrylate: 192 parts

[0104] 2-allyl-2-fluorobenzene: 223 parts

[0105] N-(4-vinylbenzyl)-N,N-dimethylamine: 23 parts

[0106] Dicumyl peroxide: 1.5 parts

[0107] Lauryl peroxide: 2 parts

[0108] Ascorbic acid: 2 parts

[0109] Di(methacryloyloxyethyl)phthalic anhydride ester: 6.0 parts

[0110] Triisopropanolamine: 2.2

[0111] Potassium hydroxide: 2.8 parts

[0112] Composition of trifluoroethyl acrylate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com