Preparation method of carboxyl alkyl type emulsion polymer

An emulsion polymer, alkyl technology, applied in the direction of coating, can solve the problems of uneven distribution of internal bonding force, large influence by temperature difference, poor durability, etc., to ensure smooth and defect-free, large molecular weight and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

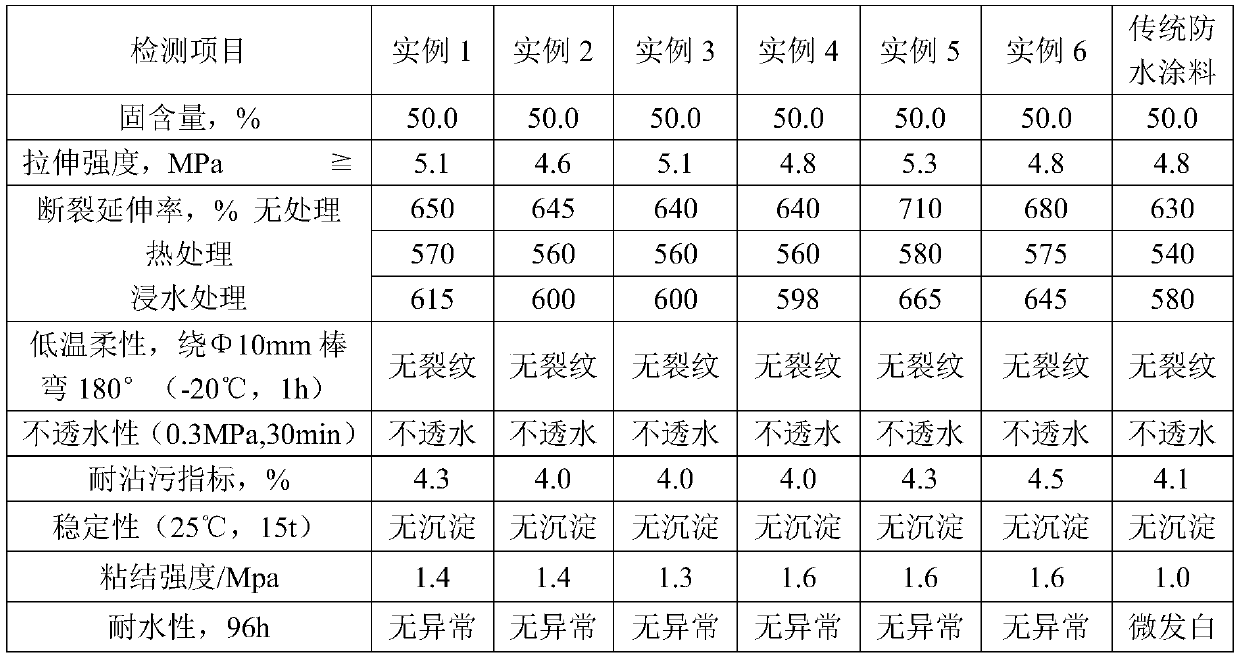

Examples

example 1

[0062] Prepare carboxyalkyl emulsion polymer, required raw material, in total mass parts 1000 parts, comprise following mass parts components:

[0063] Itaconic acid: 3.6 parts

[0064] Octadecyl vinyl ether: 8.4 parts

[0065] tert-butyl peroxyvaleric acid: 0.2 parts

[0066] Sodium methacrylate: 0.35

[0067] Two compositions of carboxyl-based hydrophilic monomers itaconic acid and aconitic acid with a mass ratio of 1:1: 13 parts

[0068] Dicyclopentadiene ethoxy acrylate: 135 parts

[0069] Octadecyl vinyl ether: 248 parts

[0070] Azobisisoheptanonitrile: 3.0 parts

[0071] The composition of diaminododecylbenzene and diaminooctadecylbenzene with a mass ratio of 1:1: 35 parts

[0072] Ethylene oxide and propylene oxide block polyether with a mass ratio of 1:1: 36 parts

[0073] Diisononyl phthalate: 4 parts

[0074] Polyethylene glycol dimethacrylate: 4.5 parts

[0075] Triisopropanolamine: 1.6 parts

example 2

[0086] Prepare carboxyalkyl emulsion polymer, required raw material, in total mass parts 1000 parts, comprise following mass parts components:

[0087] Itaconic acid: 3.6 parts

[0088] Octadecyl vinyl ether: 8.4 parts

[0089] tert-butyl peroxyvaleric acid: 0.2 parts

[0090] Sodium methacrylate: 0.35 parts

[0091] Aconitic acid: 13 parts

[0092] Dicyclopentadiene ethoxy acrylate: 135 parts

[0093] Octadecyl vinyl ether: 248 parts

[0094] Azobisisoheptanonitrile: 3.0 parts

[0095] The composition of diaminododecylbenzene and diaminooctadecylbenzene with a mass ratio of 1:1: 35 parts

[0096] Ethylene oxide and propylene oxide block polyether with a mass ratio of 1:1: 36 parts

[0097] Diisononyl phthalate: 4.0 parts

[0098] Polyethylene glycol dimethacrylate: 4.5 parts

[0099] Triisopropanolamine: 1.7 parts

[0100] Potassium carbonate: 2.3 parts

[0101] Graphene oxide: 0.3 parts

[0102] The balance is water

[0103] The preparation method is as follows:...

example 3

[0110] Prepare carboxyalkyl emulsion polymer, required raw material, in total mass parts 1000 parts, comprise following mass parts components:

[0111] Itaconic acid: 4.6 parts

[0112] Octadecyl vinyl ether: 8.4 parts

[0113] tert-butyl peroxyvaleric acid: 0.2 parts

[0114] Sodium methacrylate: 0.35 parts

[0115] Aconitic acid: 12 parts

[0116] Dicyclopentadiene ethoxy acrylate: 135 parts

[0117] Octadecyl vinyl ether: 247 parts

[0118] Composition of azobisisoheptanonitrile and dimethyl azobisisobutyrate with a mass ratio of 4:1: 3.0 parts

[0119] The composition of diaminododecylbenzene and diaminooctadecylbenzene with a mass ratio of 1:1: 35 parts

[0120] Ethylene oxide and propylene oxide block polyether with a mass ratio of 1:1: 38 parts

[0121] Diisononyl phthalate: 3.0 parts

[0122] Polyethylene glycol dimethacrylate: 4.5 parts

[0123] Triisopropanolamine: 1.6 parts

[0124] Sodium hydroxide: 2.4 parts

[0125] Graphene oxide: 0.3 parts

[0126] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com