A kind of building ceramics white toner and preparation method thereof

A technology for building ceramics and white color, applied in the field of building ceramic white toner and its preparation, can solve the problems of easy fading preparation process, insufficient whiteness, high temperature resistance, etc., and achieve the effects of reducing cost, high whiteness and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

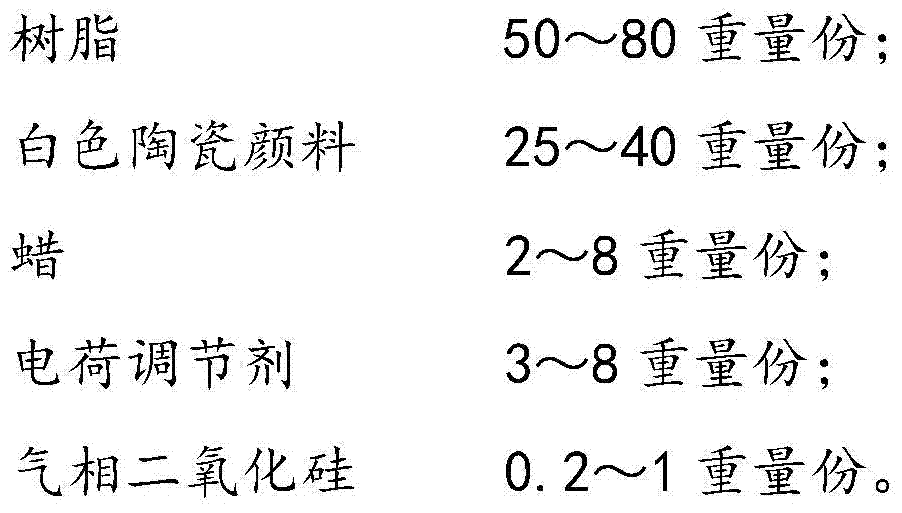

[0030] Example 1 This example discloses a white toner for architectural ceramics and a preparation method thereof. The white toner for architectural ceramics includes the following components:

[0031]

[0032] The preparation method comprises the steps of:

[0033] Preparation of modified white ceramic pigments:

[0034] a) Sol: Under the condition of stirring, the precursor of zirconia and the precursor of silicon oxide are synchronously and slowly added to the ethanol solution (50%) (the molar ratio of zirconia to silicon oxide is 4:1), after the addition is complete , stirring for hydrolysis for 24 hours, stratified after standing for 6 hours, discarding the supernatant, adding deionized water and stirring for another 24 hours, stratifying after standing for 6 hours, discarding the supernatant, repeating the above steps until the pH value of washing with water is neutral , get sol;

[0035] b) Gel: drying the sol in a drying oven to form a xerogel;

[0036] c) Calcin...

Embodiment 2

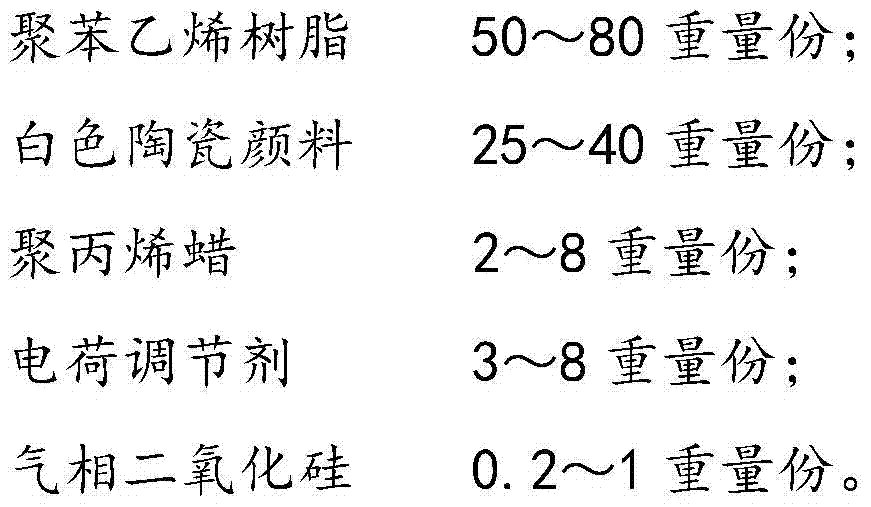

[0044] Example 2 This example discloses a white toner for architectural ceramics and a preparation method thereof. The white toner for architectural ceramics includes the following components:

[0045]

[0046] The preparation method comprises the steps of:

[0047] Preparation of modified white ceramic pigments:

[0048] a) Sol: Under the condition of stirring, the precursor of zirconia and the precursor of silicon oxide are synchronously and slowly added to the ethanol solution (50%) (the molar ratio of zirconia to silicon oxide is 4:1), after the addition is complete , stirring for hydrolysis for 24 hours, stratified after standing for 6 hours, discarding the supernatant, adding deionized water and stirring for another 24 hours, stratifying after standing for 6 hours, discarding the supernatant, repeating the above steps until the pH value of washing with water is neutral , get sol;

[0049] b) Gel: drying the sol in a drying oven to form a xerogel;

[0050] c) Calcin...

Embodiment 3

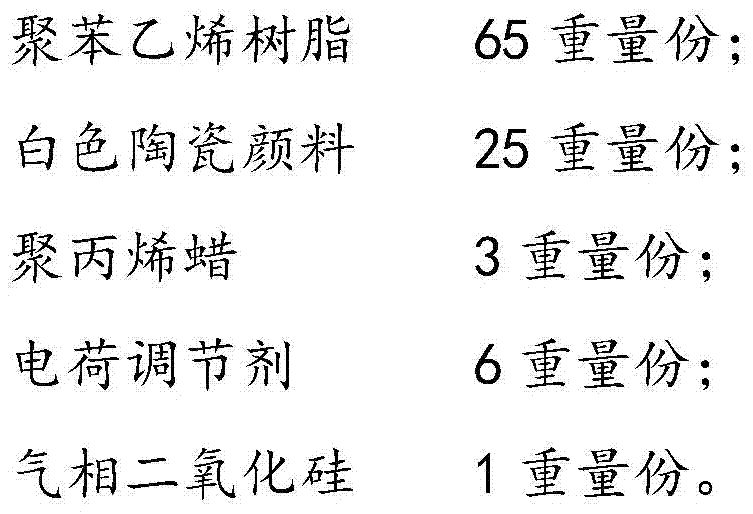

[0058] Embodiment 3 This embodiment discloses a white toner for architectural ceramics and a preparation method thereof. The white toner for architectural ceramics includes the following components:

[0059]

[0060] Described its preparation method, comprises the steps:

[0061] Preparation of modified white ceramic pigments:

[0062] a) Sol: Under the condition of stirring, the precursor of zirconia and the precursor of silicon oxide are synchronously and slowly added to the ethanol solution (50%) (the molar ratio of zirconia to silicon oxide is 4:1), after the addition is complete , stirring for hydrolysis for 24 hours, stratified after standing for 6 hours, discarding the supernatant, adding deionized water and stirring for another 24 hours, stratifying after standing for 6 hours, discarding the supernatant, repeating the above steps until the pH value of washing with water is neutral , get sol;

[0063] b) Gel: drying the sol in a drying oven to form a xerogel;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com