A kind of preparation method of benzene ring type core-shell emulsion polymer for cement

A technology of core-shell emulsion and polymer, which is applied in the field of building surface waterproofing and bonding coatings, and building materials, can solve the problems of coating stain resistance, heat resistance and water resistance at the same time, and achieve narrow molecular weight distribution range, Strengthen the internal bonding force and the effect of good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

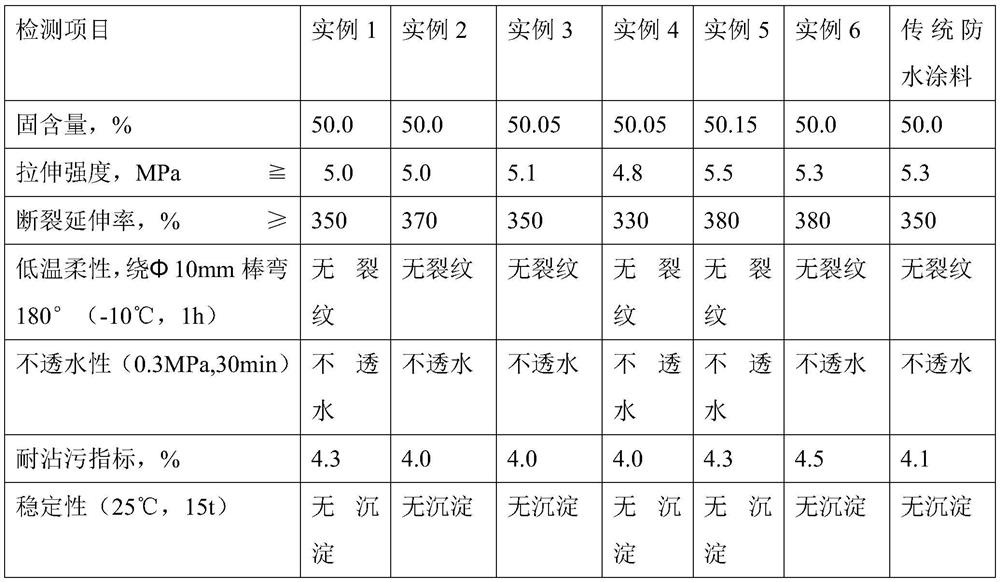

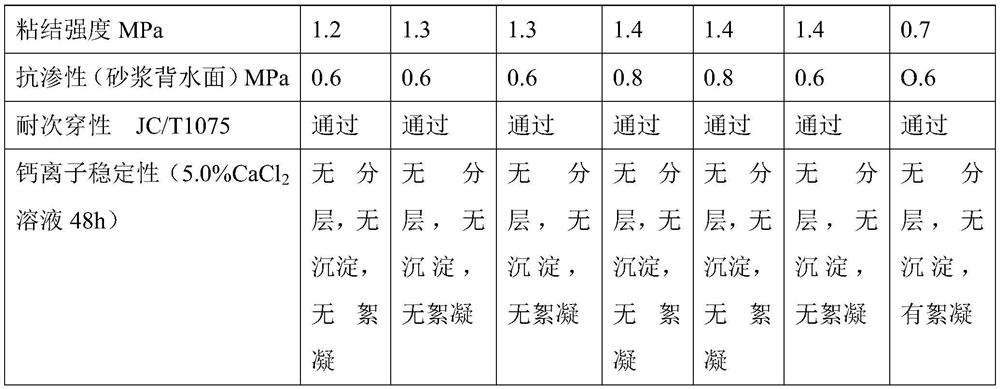

Examples

example 1

[0050] A preparation method of benzene ring core-shell emulsion polymer for cement, which is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and the components and process parameters are as follows:

[0051] Methacryl alcohol: 3.5 parts

[0052] 1-Phenylvinylboronic acid: 14.5

[0053] Dicyclohexyl peroxydicarbonate: 0.3 parts

[0054] Sodium methacrylate: 0.5 parts

[0055] Prenol: 9 parts

[0056] 2-ethylhexyl acrylate: 200 parts

[0057] 1-Phenylvinylboronic acid: 230 parts

[0058] Benzoyl peroxide: 1.5 parts

[0059] Di-tert-butyl peroxide: 1.5 parts

[0060] Sodium hypophosphite: 2.0 parts

[0061] Combination of bis(methacryloxyethyl) pyrophthalic anhydride ester and hydroxyethyl pyrophthalic anhydride dimethacrylate with a mass ratio of 1:1: 4 parts

[0062] Diethanolamine: 1.2 parts

[0063] Sodium bicarbonate: 2.8 parts

[0064] The composition of trifluoroethyl acrylate and perfluorooctyl ethyl acrylate with ...

example 2

[0072] A preparation method of benzene ring core-shell emulsion polymer for cement, which is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and the components and process parameters are as follows:

[0073] Methacryl alcohol: 3.5 parts

[0074] 1-Phenylvinylboronic acid: 14.5

[0075] Composition of dicyclohexyl peroxydicarbonate and tert-butyl peroxy tert-valerate with a mass ratio of 3:1: 0.3 parts

[0076] Sodium methacrylate: 0.5 parts

[0077] Prenol: 9 parts

[0078] 2-ethylhexyl acrylate: 200 parts

[0079] 1-Phenylvinylboronic acid: 230 parts

[0080] Benzoyl peroxide: 1.5 parts

[0081] Di-tert-butyl peroxide: 1.5 parts

[0082] Composition of sodium dithionite and ascorbic acid with a mass ratio of 1:3: 2.0 parts

[0083] Combination of bis(methacryloxyethyl) pyrophthalic anhydride ester and hydroxyethyl pyrophthalic anhydride dimethacrylate with a mass ratio of 1:1: 4 parts

[0084] Diethanolamine: 1.4 parts ...

example 3

[0094] A preparation method of benzene ring core-shell emulsion polymer for cement, which is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and the components and process parameters are as follows:

[0095] Methacryl alcohol: 3.5 parts

[0096] 1-Phenylvinylboronic acid: 14.5

[0097] Dicyclohexyl peroxydicarbonate: 0.3 parts

[0098] Sodium methacrylate: 0.5 parts

[0099] Composition of 4-(ethyleneoxy)-1-butanol and isopentenol with a mass ratio of 1:1: 9 parts

[0100] 2-ethylhexyl acrylate: 200 parts

[0101] 1:2 composition of 1-phenylvinylboronic acid and 4-methoxy-2-vinylaniline: 230 parts

[0102] Benzoyl peroxide: 1.5 parts

[0103] Di-tert-butyl peroxide: 1.5 parts

[0104] Sodium hypophosphite: 2.0 parts

[0105] Combination of bis(methacryloxyethyl) pyrophthalic anhydride ester and hydroxyethyl pyrophthalic anhydride dimethacrylate with a mass ratio of 1:1: 4 parts

[0106] Diethanolamine: 1.5 parts

[0107]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com