Process for producing straw artificial board

A production process and wood-based panel technology, applied in the direction of manufacturing tools, wood processing equipment, sugarcane machining, etc., can solve the problems of cumbersome production process, damage to straw fiber structure, and discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

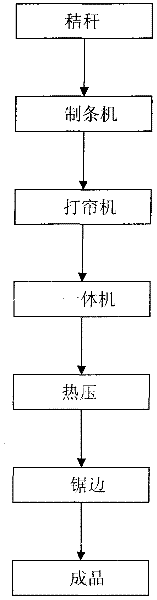

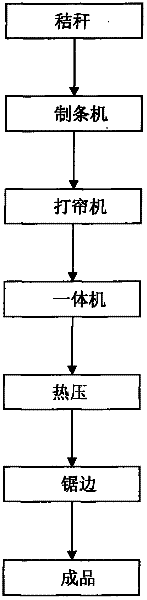

Image

Examples

Embodiment 1

[0014] First, one of the four kinds of straws is sent to the whole straw making machine, and the whole straw is processed longitudinally by the making machine into 6mm wide straw strips, the length of which is the natural length of each straw, and then the 6mm The wide stalks are fed into the curtain tying machine, and the stalks are woven by the curtain tying machine into sheet-like stalk curtains with two different stalk placements of the same shape and size, that is, the vertical length of the stalks is 2700mm × horizontal 1300mm ×Layer thickness 10mm This arrangement method makes two pieces, and then according to the arrangement method of 1300mm in the vertical direction of the stalks × 2700mm in the horizontal direction × Layer thickness of 10mm, make one piece, three pieces form a group, and send the three pieces of stalk curtain The integrated machine for drying, glue spraying and billet assembly of double-roller stalk curtains is integrated to complete the work of dryin...

Embodiment 2

[0016] After drying, glue spraying and slab assembly by the integrated machine, before sending it into the hot press, if you want to produce a veneer board, you can stick the veneer of wood veneer or other materials on the back surface of the slab Send into hot press machine again after two sides, just can directly send slab into hot press machine as producing plain panel material, other process conditions are like embodiment 1, can produce qualified panel material equally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com