High-strength wear-resistant wood-plastic composite material and preparation method thereof

A composite material, high-strength technology, applied in the field of polymer composite material preparation, can solve the problems of limiting the use range of wood-plastic composite materials, low strength and anti-wear performance of wood-plastic composite materials, reducing internal energy consumption and improving resistance to wear. Grinding effect, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

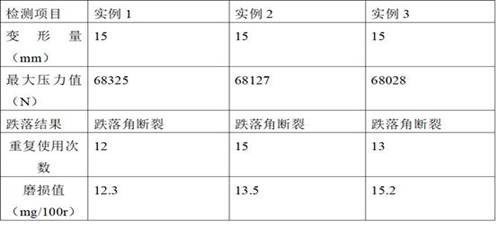

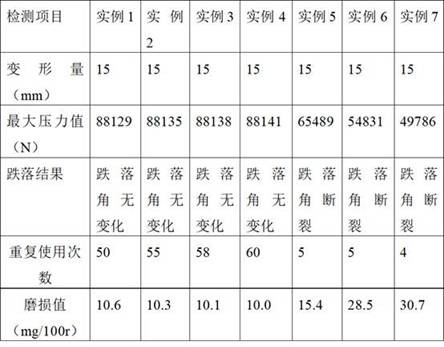

Examples

preparation example Construction

[0056] During the preparation of wood-plastic composite materials:

[0057] (1) Pretreatment of raw materials: The manufacture of wood-plastic composite materials is based on the treatment of raw materials. First, the treatment of wood chips. Through repeated freezing and thawing, the pore structure of wood chips is widened, and the specific surface area of wood chips is increased. The contact probability of large wood chips and plastics improves the compatibility of the two, thereby improving the cohesion of wood-plastic composites and increasing the mechanical strength of wood-plastic composites; followed by the modification of plastics, first using sodium silicate and hydrochloric acid to react Produce orthosilicic acid precipitation, and then hydrolyze the orthosilicic acid precipitation to produce nano-silica particles under high temperature conditions, thereby obtaining silica sol; then add mussel mucin, because there are more than 10% of mussel mucin peptide chain frag...

example 1

[0065] (1) Treatment of sawdust:

[0066] Weigh the sawdust and immerse it in deionized water for 15 hours, take out the soaked sawdust and immediately spray and freeze it with liquid nitrogen for 2 minutes, heat up to 40°C for 10 minutes after spraying, and repeat the freezing and thawing treatment for 5 times to obtain treated wood chips ;Through repeated freezing and thawing, the pore structure of wood chips is widened, thereby increasing the specific surface area of wood chips, which can increase the contact probability of wood chips and plastics, improve the compatibility of the two, and then improve the cohesion of plastic wood pallets, increase the plastic wood The mechanical strength of the tray;

[0067](2) Pour the sodium silicate solution with a concentration of 0.5mol / L into the beaker, adjust the pH to 6.0 with hydrochloric acid with a concentration of 1mol / L, stir the reaction with a magnetic stirrer at a speed of 300r / min for 1h, and transfer to In the reacti...

example 2

[0078] (1) Treatment of sawdust:

[0079] Weigh the sawdust and immerse it in deionized water for 16 hours, take out the soaked sawdust and immediately spray and freeze it with liquid nitrogen for 3 minutes, heat up to 42°C for 12 minutes after spraying, and repeat freezing and thawing for 6 times to obtain treated wood chips ;Through repeated freezing and thawing, the pore structure of wood chips is widened, thereby increasing the specific surface area of wood chips, which can increase the contact probability of wood chips and plastics, improve the compatibility of the two, and then improve the cohesion of plastic wood pallets, increase the plastic wood The mechanical strength of the tray;

[0080] (2) Pour the sodium silicate solution with a concentration of 0.5mol / L into the beaker, adjust the pH to 6.0 with hydrochloric acid with a concentration of 1mol / L, stir the reaction with a magnetic stirrer at a speed of 320r / min for 1h, and transfer it to In the reaction kettle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com