Board conveying and shaping device

A technology for shaping device and plate, which is applied in the direction of wood processing utensils, joining of wooden veneers, and manufacturing tools, etc., can solve the problems of multiple production turnover sites, decreased product qualification rate, heavy plate weight, etc., to shorten the production cycle, The effect of improving quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Now in conjunction with accompanying drawing and embodiment the present invention is described in detail:

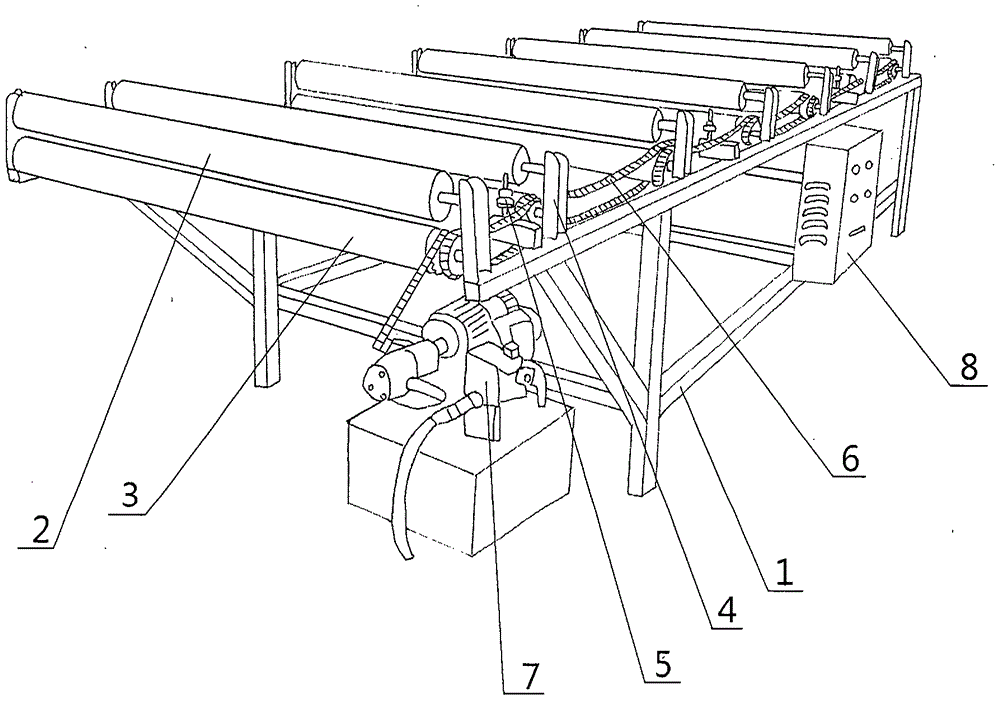

[0045] The present invention is composed of a frame body (1), a pressure setting roller (2), a conveying roller (3), a roller fixed groove frame (4), a plate positioning roller (5), a chain (6), a motor unit (7), Power box (8) forms.

[0046] figure 1Shown is the structural representation of the present invention. Wherein, 1 is a frame body, 2 is a pressure setting roller, 3 is a conveying roller, 4 is a roller fixing groove frame, 5 is a plate positioning roller, 6 is a chain, 7 is a motor unit, and 8 is a power supply box.

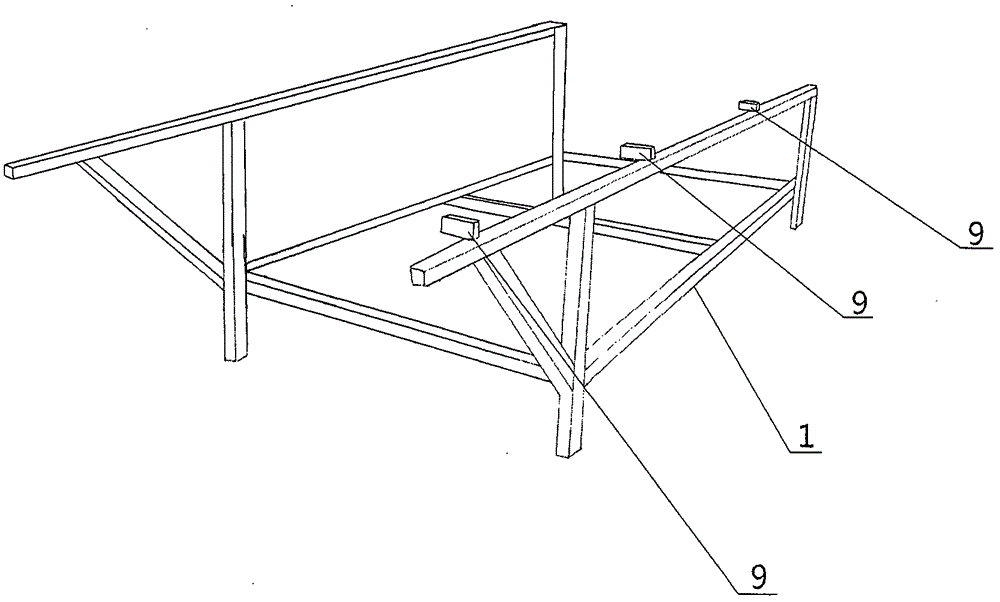

[0047] figure 2 Shown is a schematic structural view of the frame (1) in the present invention. The frame body (1) is a square three-dimensional frame, and the top of the frame body (1) is provided with a positioning roller frame (9), and there are several positioning roller frames (9).

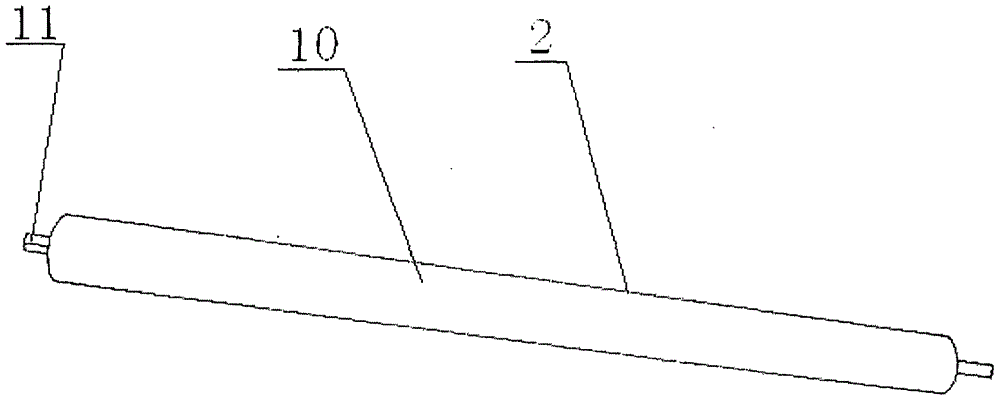

[0048] image 3 Shown is the structural schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com