System capable of conducting heating and drying simultaneously during board conveying

A sheet and drying technology, applied in the direction of veneer drying, heating device, drying of solid materials, etc., can solve the problems of affecting continuous production, failure to repair, easy to stick to the roller, etc., to achieve easy control of dry humidity and drying speed. The effect of fast and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with accompanying drawing and embodiment the present invention is described in detail:

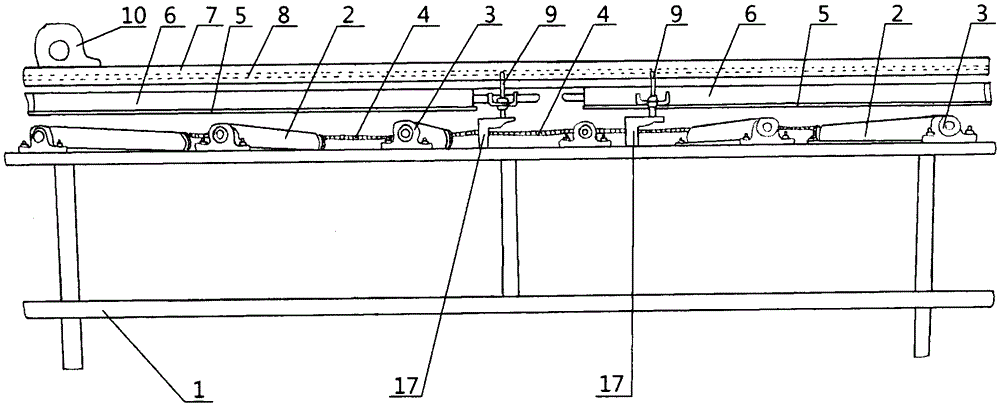

[0026] The present invention is made up of frame body (1), conveying and heating dual-function roller (2), bearing seat (3), chain (4), plate circulation guide plate (5), radiator (6), heat preservation wind hood ( 7), wind-blocking and air-discharging hole metal mesh (8), fastening piece (9), air blower (10).

[0027] figure 1 Shown is the structural representation of the present invention.

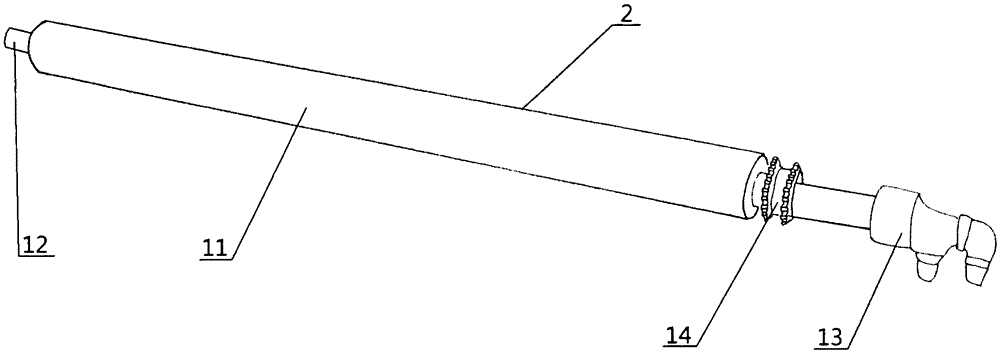

[0028] figure 2 Shown is the structural schematic diagram of the conveying and heating dual-function roller (2) in the present invention.

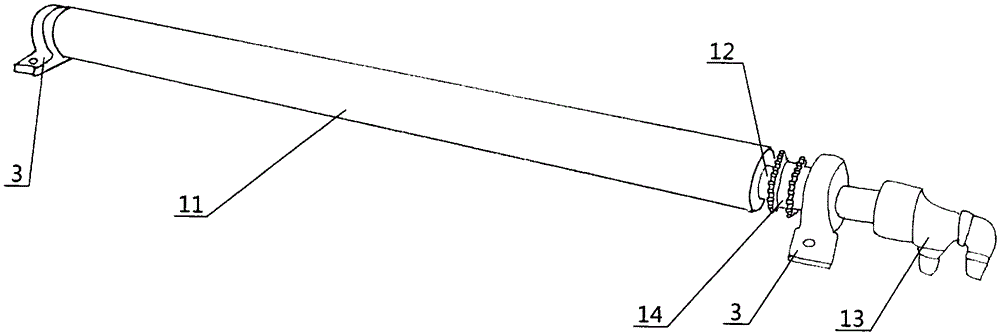

[0029] image 3 Shown is a structural schematic diagram of the combination of the conveying and heating dual-function roller (2) and the bearing seat (3) in the present invention.

[0030] Figure 4 Shown is a schematic structural view of the radiator (6) in the present invention.

[0031] From figure 1 , figure 2 , image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com