Residue and juice separation device for food processor

A food processing machine and slag juice separation technology, which is applied in the direction of household machinery, household appliances, and applications for filtering food, can solve the problems of poor juicing effect, incomplete separation of slag juice, and waste of juice, so as to improve juicing. effect, avoid incomplete separation of juice residue, and prolong the effect of pressing path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

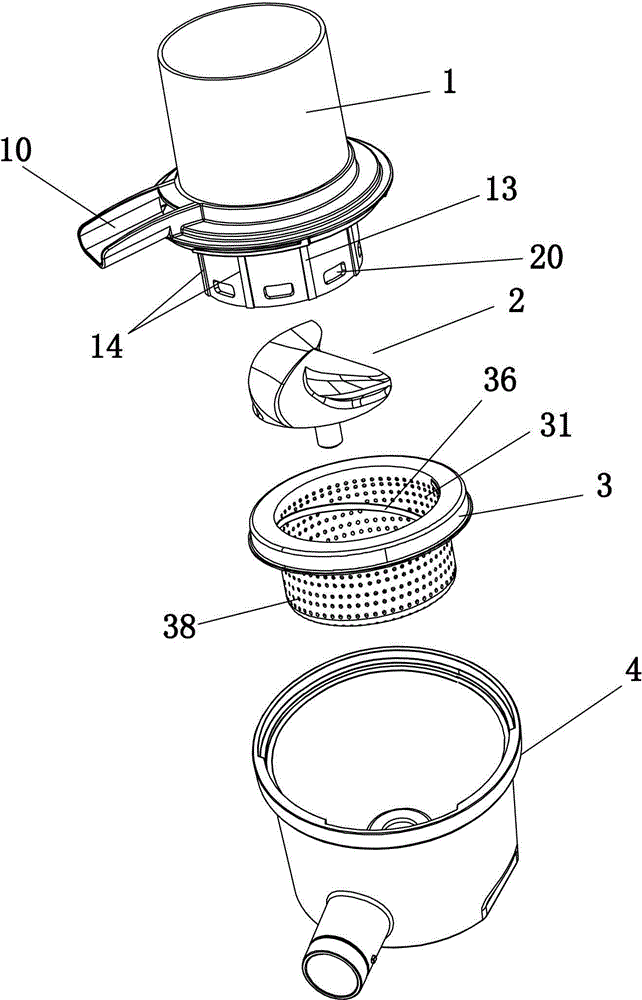

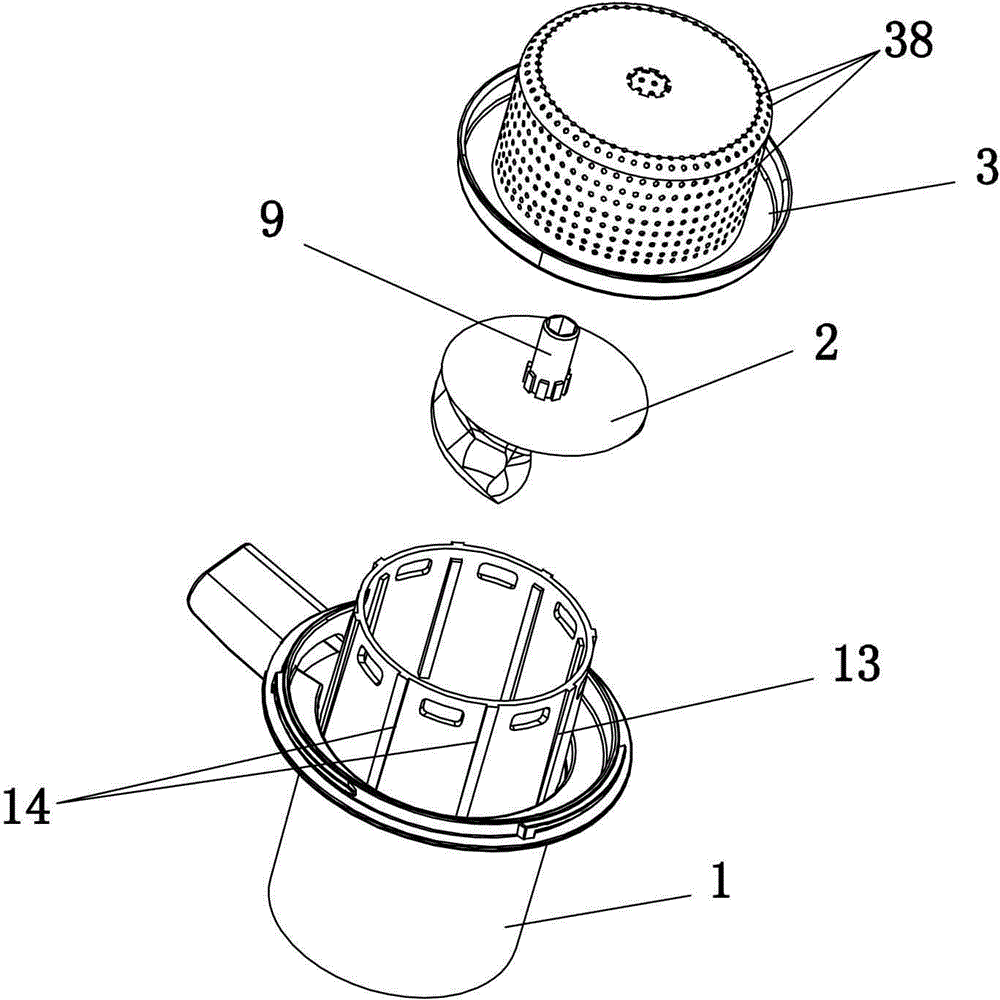

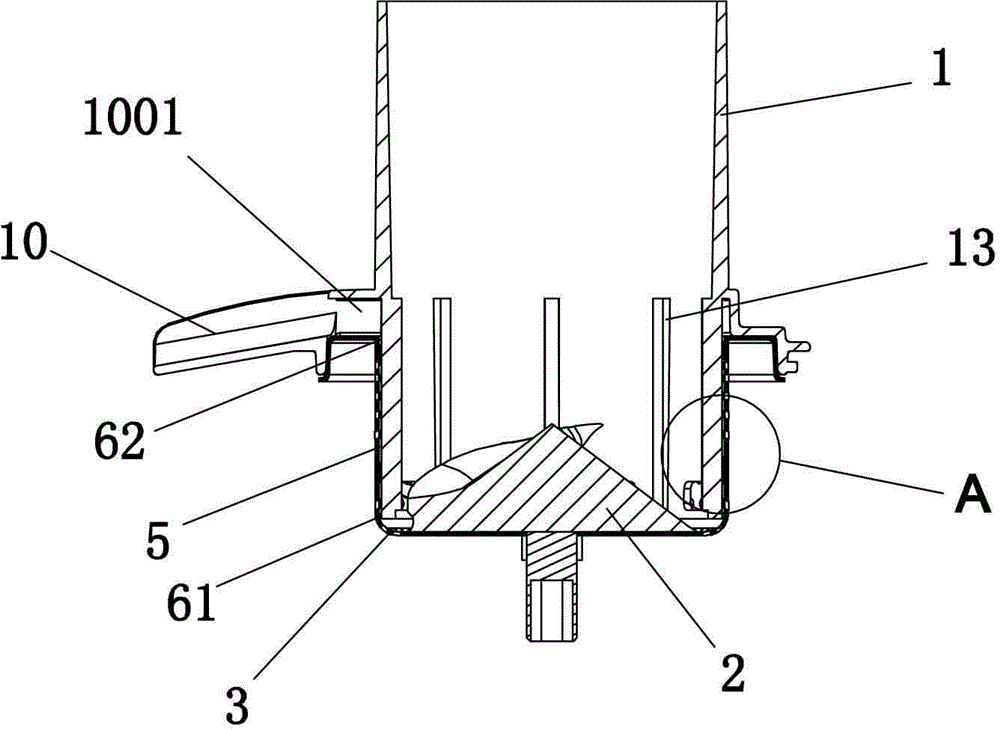

[0037] Embodiment one: if Figure 1 to Figure 6 As shown, a food processor slag juice separation device includes an inner channel 1 and a food preprocessor 2. The food preprocessor 2 is a chopper, which is arranged at the bottom of the inner channel 1 and the outer layer of the filter screen through a transmission shaft 9. 3, and connected with the filter screen outer layer 3. It is characterized in that it also includes a filter screen outer layer 3 and a juice receiving container 4, the filter screen outer layer 3 is arranged on the outside of the inner channel 1, and there is a gap 5 between the two, the filter screen outer layer 3 and the inner channel 1 They are arranged on the juice receiving container 4 together, and a squeeze channel 6 extending from bottom to top is arranged in the gap 5, and the squeeze channel 6 has at least one inclined section 63, the inlet 61 of the squeeze channel 6 is on the bottom, the outlet 62 is on the top, and the inlet 61 communicates wi...

Embodiment 2

[0043] Embodiment two: if Figure 7 and Figure 8 As shown, this embodiment is similar to the above-mentioned embodiment 1, the difference is only: the inner wall 31 of the outer layer of the filter screen in the gap 5 is provided with a flange 37 extending spirally from bottom to top, and the convex The edge 37 is against or close to the outer wall 11 of the inner passage, so that the spirally extending flange 37 separates the squeeze passage 6 extending spirally from bottom to top in the gap 5; that is to say, in this embodiment, through The flange 37 of the inner wall 31 of the outer layer of the filter screen is arranged to extend in a spiral shape instead of the arc-shaped extension of the first embodiment above, so that a spirally extending squeeze channel 6 is formed in the gap 5; this spirally extended squeeze channel 6 The squeezing path can be further extended, which is conducive to further improving the uniformity and squeezing effect of the squeezing, and the sque...

Embodiment 3

[0045] Embodiment three: as Figure 9-Figure 13 As shown, a food processing machine slag juice separation device includes an inner channel 1, a food preprocessor 2, a filter screen outer layer 3 and a juice receiving container 4, the filter screen outer layer 3 is arranged on the outside of the inner channel 1, and two There is a gap 5 between them, and the outer layer of the filter screen 3 and the inner channel 1 are arranged in the juice receiving container 4 together, and the outer wall 11 of the inner channel in the gap 5 is provided with a convex spiral extending from bottom to top. The flange 38, the flange 38 is against or close to the inner wall of the outer layer of the filter screen, so that the spirally extending flange 38 separates the squeeze channel 6 extending spirally from bottom to top in the gap 5, and the spirally extending The squeeze channel 6 of the same at least has an inclined section 63, the squeeze channel inlet 61 is on the bottom, the outlet 62 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com