Circuit board laminating machine

A circuit board and laminator technology, applied in lamination, lamination devices, layered products, etc., can solve the problem that the production efficiency cannot meet the requirements of circuit board manufacturing, the degree of automation of material preparation and feeding devices is not high, and the control is unreliable, etc. problems, to achieve the effect of saving working time, saving space, and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

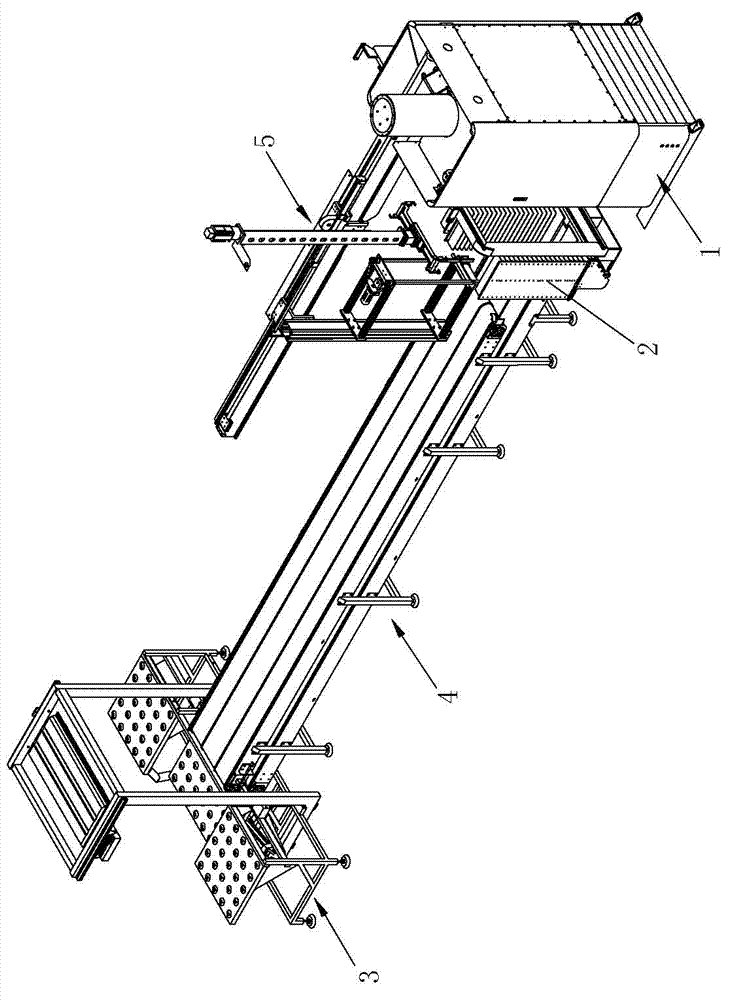

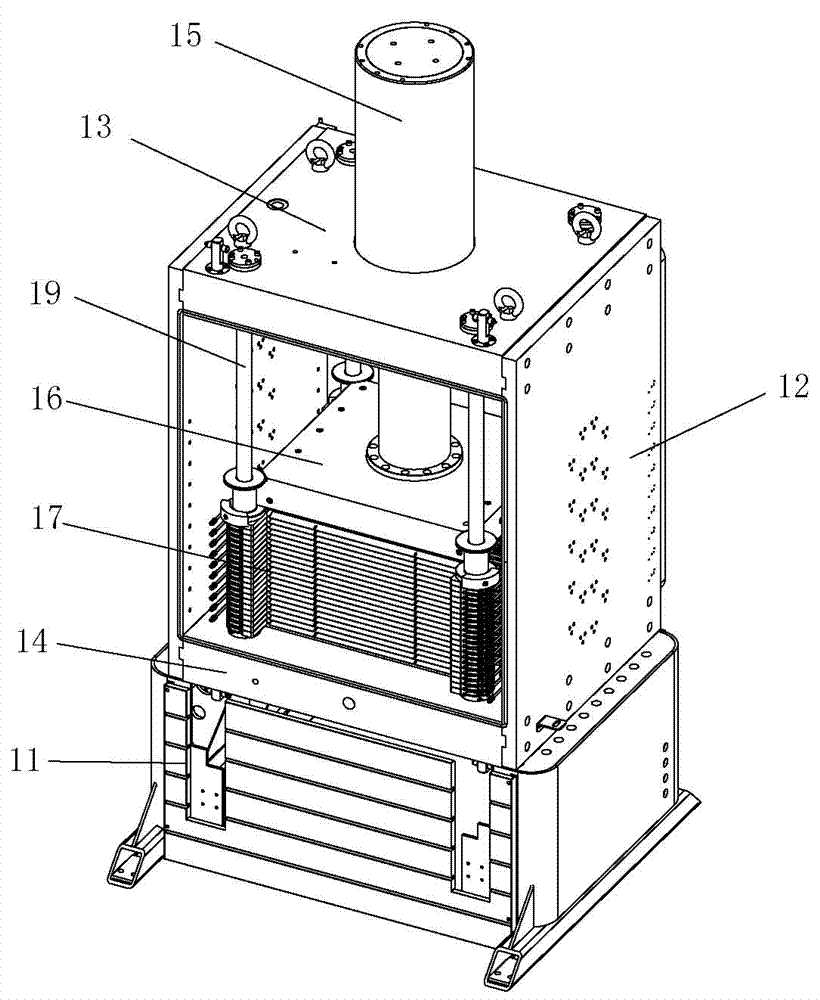

[0034] See Figure 1 to Figure 12 , a circuit board laminating machine, which includes a control system, a laminating device 1, a lifting device 3, a conveying device 4 with a double-layer conveying structure, and a cantilever type feeding and unloading device 5, and the board inlet of the laminating device 1 The material bracket 2 is slidingly connected, the lifting device 3, the conveying device 4 and the laminating device 1 are arranged in sequence, the cantilever feeding and unloading device 5 is fixedly installed on the top of the laminating device 1, and the control system is connected with the cantilever feeding and unloading device respectively. Material device 5 and laminating device 1 are controlled and connected.

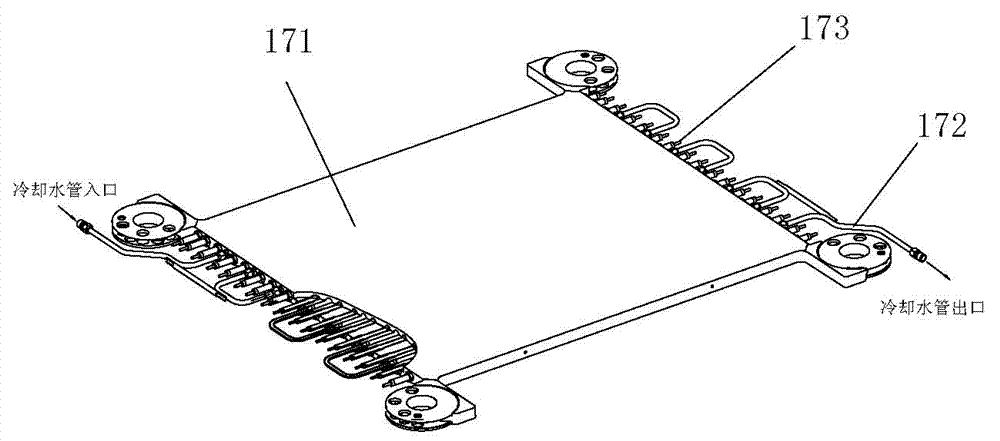

[0035] Wherein, the lifting device 3 is used for lifting and lowering the prepared circuit board. like figure 2 and image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com