Pressing module for testing drawing force of keycap and test machine for drawing force of keycap

A pulling force and testing machine technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of strong human subjectivity, limited fatigue endurance of probes, difficult maintenance, etc., and the reach is controllable Clearance adjustment, efficient overcoming friction, easy replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing of description, the present invention will be further described.

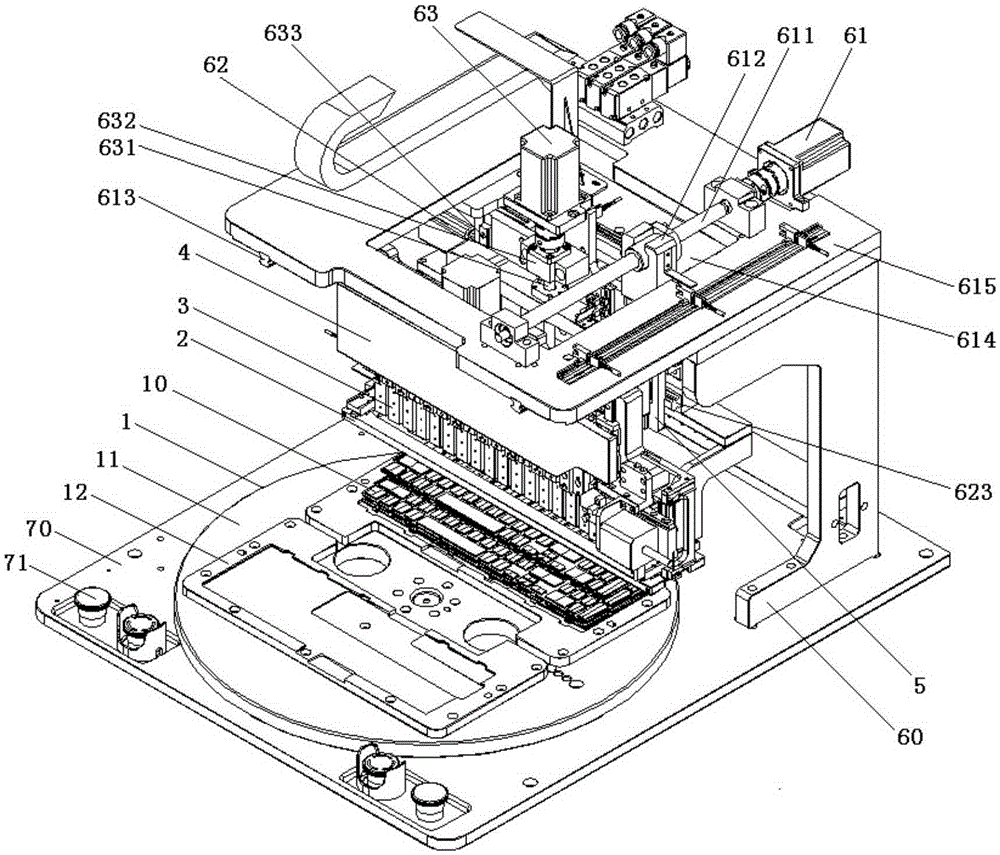

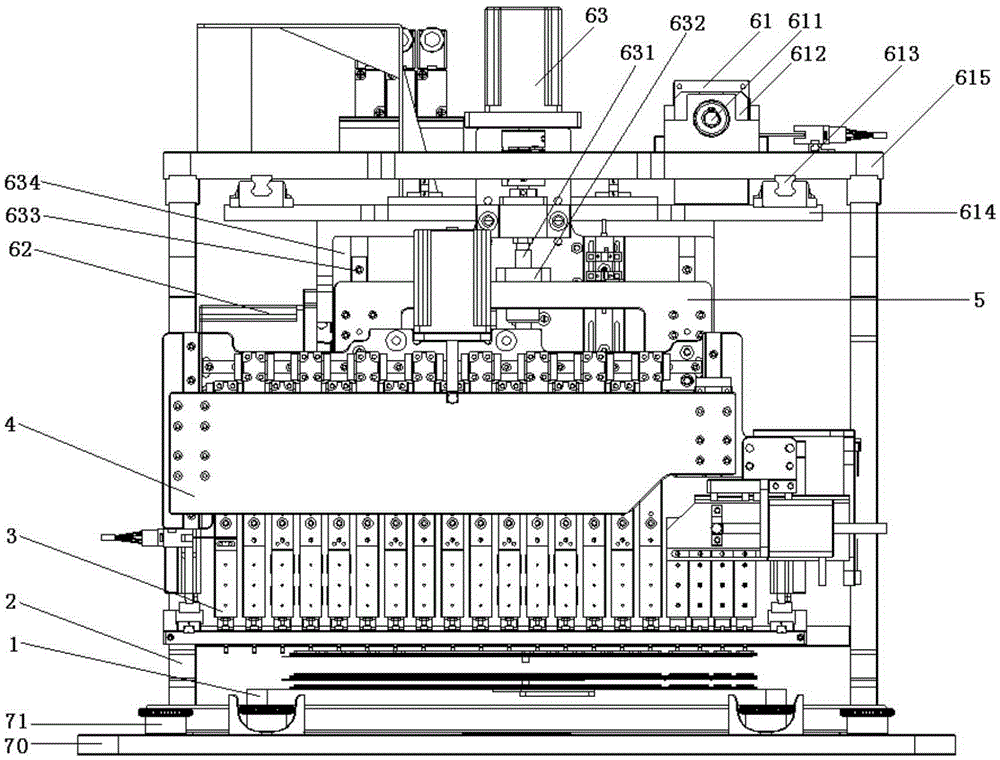

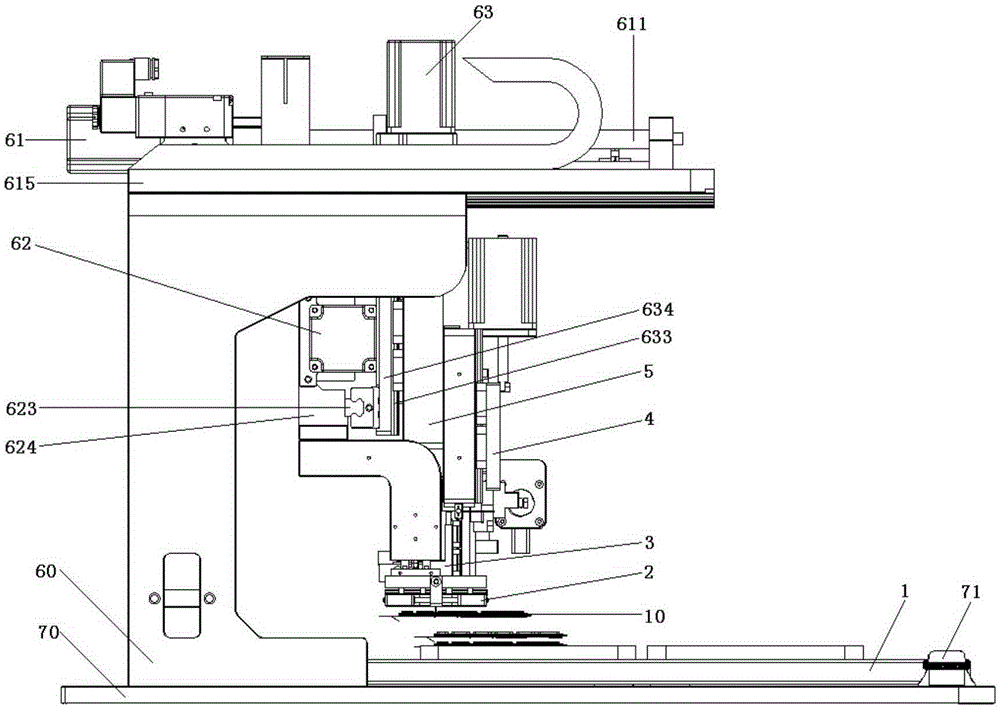

[0044] Such as Figure 1 to Figure 4 A keycap pulling force testing machine is shown, comprising: a keyboard placement device 1 for placing and inputting a keyboard 10 to be tested; a pressing module 2 for testing a keycap pulling force for pressing the keyboard 10; The pull-out force test head assembly 3 is used to perform a pull-out force test on the keycap in the pressed keyboard 10; the telescopic module 4 is used to suspend the test head assembly 3 and adjust the distance; the base plate 5 is used to fix the telescopic module 4. The driving device 6 is used to drive the substrate 5 to move in the X-axis, Y-axis and Z-axis directions.

[0045] Such as Figure 5 As shown, the keycap pulling force testing machine also includes a frame 7, a test button 71 arranged on the frame 7, an electric control box 72, a test control keyboard 73, a display screen 74 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com