Method of treating wool fabric using transglutaminase

A transglutaminase and enzyme treatment technology, which is applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems that anti-wrinkle technology cannot be used, it is unfavorable to environmental protection, and its durability is not strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Improvement of pressing performance

[0017] Select two woolen fabric samples, about 70 grams each, bath ratio 1:15, enzyme concentration 2.5% (o.w.f.). First, the two cloth samples are pretreated with distilled aqueous solution at 43 degrees Celsius (time 30 minutes), and then respectively in The enzyme solution at 50 degrees centigrade and the water at 50 degrees centigrade were each treated for 1 hour, then washed with tap water and dried in the air. Cut fabric samples with a specification of 40*20mm, and iron them with an iron at 100 degrees Celsius for 3.5 minutes (without getting wet). After different recovery times, the changes in their pressing angles are measured in Table 1:

[0018] Experiment number

[0019] It can be seen from the data that the pressing angle of the enzyme-treated fabric is significantly smaller than that of the untreated fabric. After 3.5 minutes of recovery, the reduction rate reaches 26.4%; after 1 hour of recovery...

Embodiment 2

[0020] Example 2: Improvement of Dimensional Stability

[0021] There are 3 pieces of cut fabric samples, the size is similar, and the weight of the fabric samples is about 22.5 grams. The quality of finished enzyme 1, finished enzyme 2 is all got 0.75 gram, aqueous solution 450ml, bath ratio 1: 20, concentration is 3.3% (o.w.f.). Without pretreatment, soak the fabric in the corresponding solution for 90 minutes, and the test temperature is still 50 degrees Celsius to ensure sufficient reaction. The numbers of the treated samples are 1, 2, and 3, corresponding to finished enzyme 1 treatment, finished enzyme 2 treatment and blank samples.

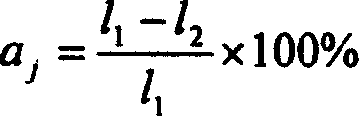

[0022] Before enzymatic treatment, iron the three fabrics flat, and mark the stitches of L1 (100mm) with a ruler. After the treatment, put the fabric in the washing machine for washing, rinsing, drying, and drying, then iron the fabric, measure the length L2 of the stitches, and calculate the warp shrinkage aj. The test data are shown in T...

Embodiment 3

[0026] Example 3: Improvement of wrinkle resistance

[0027] There are 3 pieces of cut fabric samples, the size is similar, and the weight of the fabric samples is about 22.5 grams. The quality of the finished enzyme 1 and the finished enzyme 2 is 0.75 grams, and the aqueous solution is 450 ml, and the concentration is 3.3% (o.w.f.). Without pretreatment, the fabric is soaked in the solution for 90 minutes, and the test temperature is still 50 degrees Celsius to ensure sufficient reaction. Three samples of the same specification were treated with finished enzyme 1 treatment (No. 1), finished enzyme 2 treatment (No. 2) and blank sample (No. 3).

[0028] The fabric samples were washed properly, hung, and several uninformed professionals were invited to evaluate the wrinkle condition. The results agreed that No. 1 was the best in terms of wrinkle resistance of wool fabrics, followed by No. 2. The No. 3 enzyme is the worst, indicating that the wrinkle resistance of the enzyme-tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com