Timing gear locating device and timing gear assembling equipment comprising same

A timing gear and positioning device technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as unqualified quality, and achieve the effect of improving the degree of automation, precise positioning, and ensuring the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

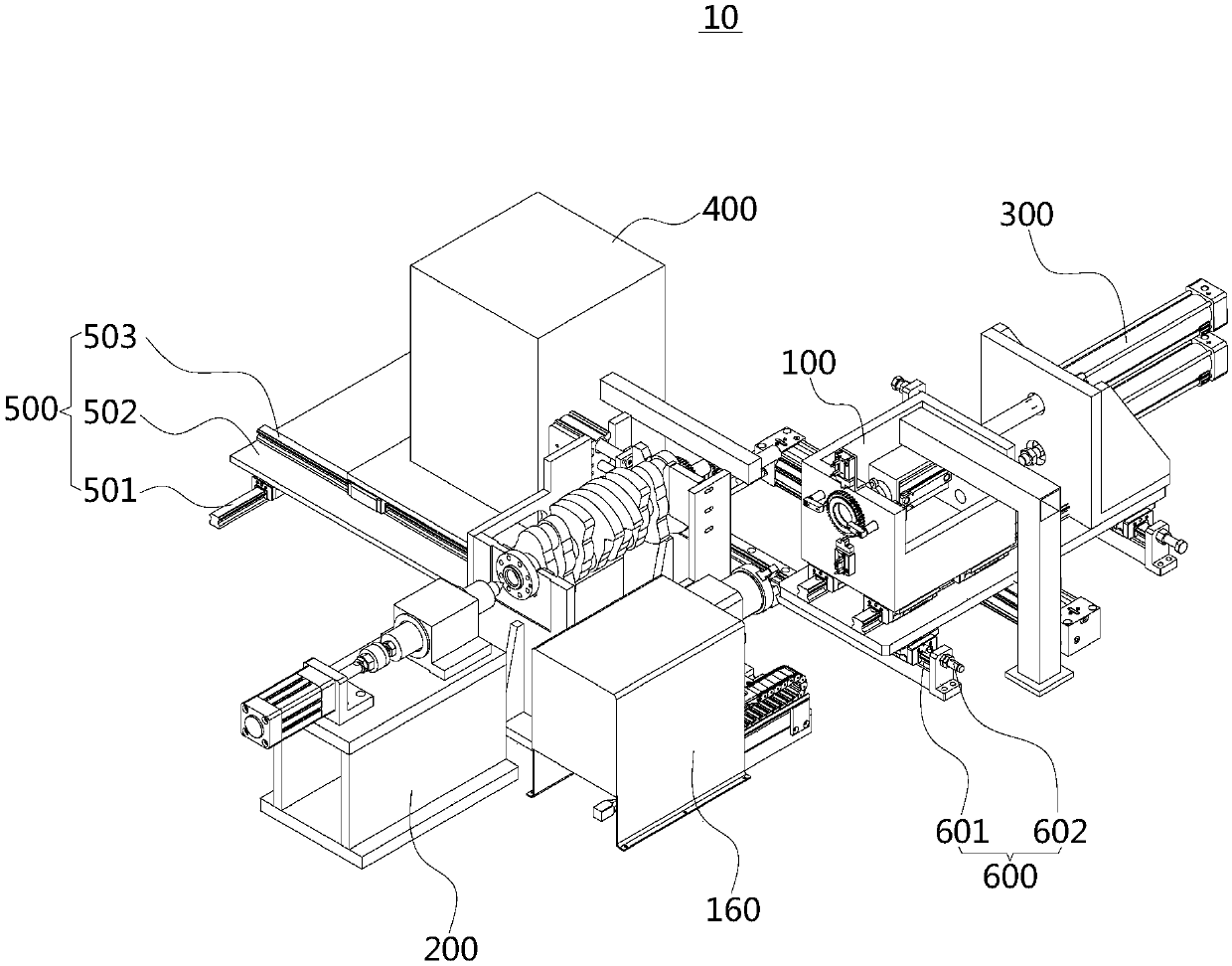

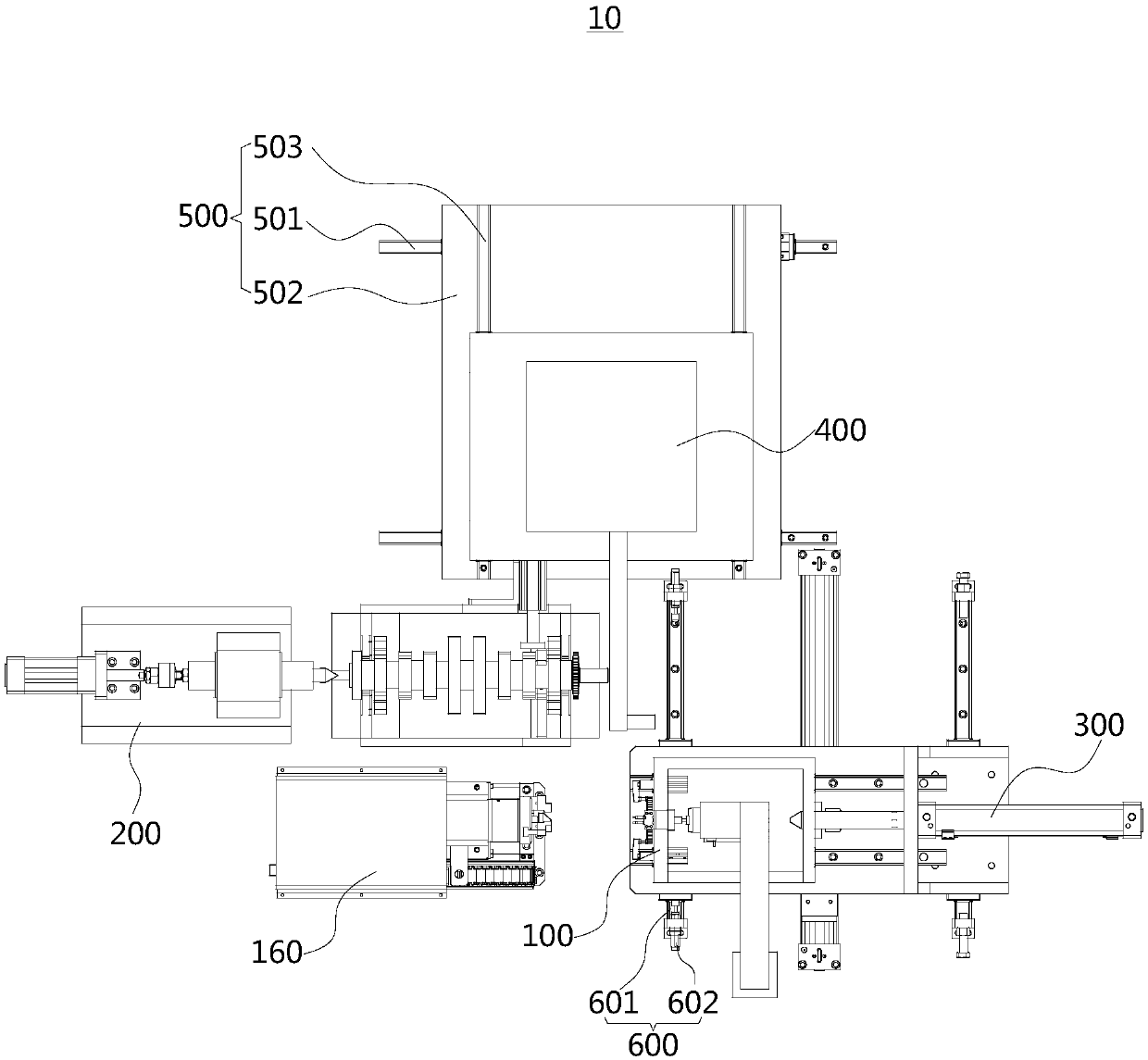

[0041] Please refer to figure 1 and figure 2 , the present embodiment provides a timing gear assembly equipment 10, which includes a workbench (not shown in the figure) and a timing gear positioning device 100, a crankshaft positioning device 200 and a press-fitting device 300 installed on the workbench. The working principle of the timing gear assembly equipment 10 is: utilize the timing gear positioning device 100 to position the timing gear 110, utilize the crankshaft positioning device 200 to position the crankshaft 201, and then utilize the press-fitting device 300 to position the positioned timing The gear 110 is press-fitted onto the positioned crankshaft 201 to complete the assembly.

[0042] Next, the specific structures of the timing gear positioning device 100 , the crankshaft positioning device 200 and the press-fitting device 300 and their mutual cooperation will be described in detail.

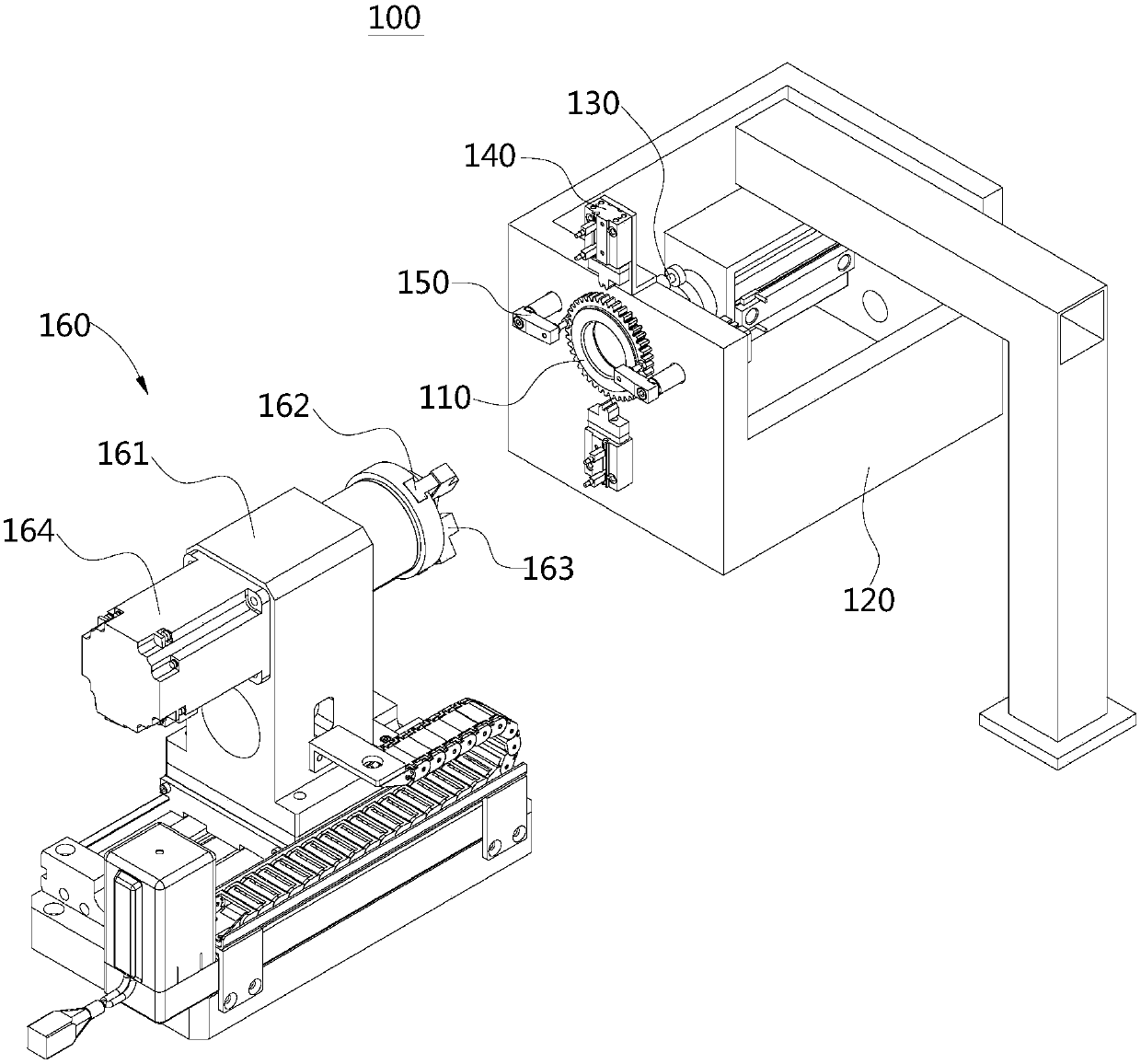

[0043] Wherein, the structure of the timing gear positioning device 100 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com