Press-mounting machine

A press-fitting machine and press-fitting technology, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of difficult press-fitting of conductive voltage coils and unguaranteed quality, and achieve simple structure, good press-fitting effect, and easy assembly solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

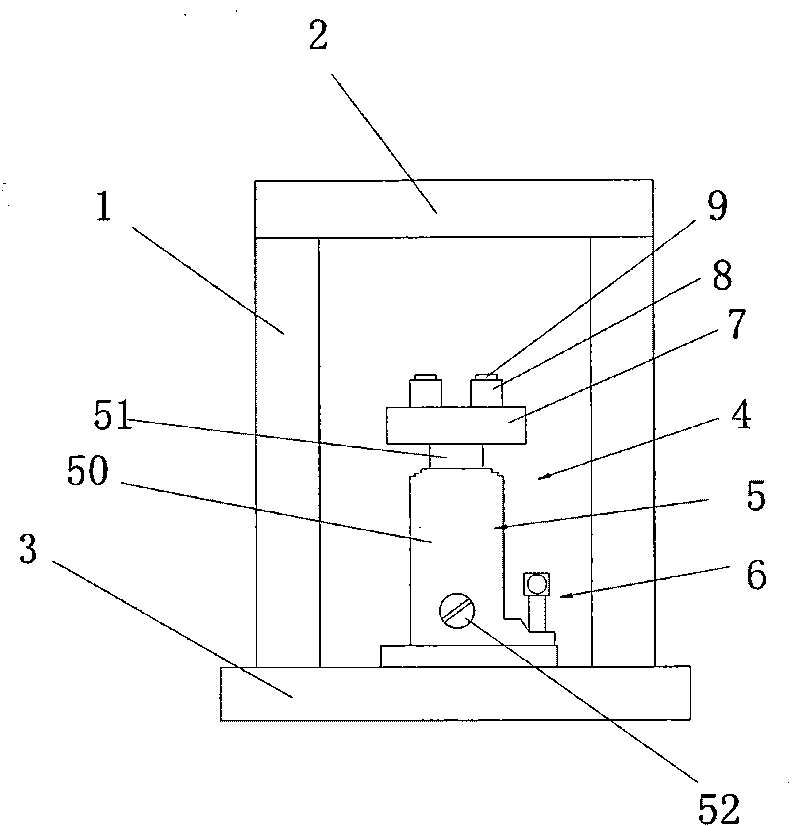

[0021] Such as image 3 As shown, the preferred embodiment of the pressing machine of the present invention is a flashlight conducting coil pressing machine, which includes a base 3, a support 1 with a top plate 2, a pressing device 4 arranged on the base 3, and the support 1 is installed on the base 3 Above, the press-fitting device 4 is arranged on the base 3; the press-fitting device 4 includes a hydraulic jacking device 5 and a press-fitting tool set on the top of the hydraulic jacking device 5, and the press-fitting tooling includes a bottom plate 7 installed on the top of the hydraulic jacking device , and several bosses 8 arranged on the bottom plate 7, the top of the bosses 8 is provided with a boss 9 matching the shape of the flashlight conductive coil.

[0022] In a preferred embodiment of the present invention, the hydraulic jacking device 5 is a manual hydraulic jack, see image 3 , The manual hydraulic jack includes a hydraulic cylinder 50, a piston 51, a manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com