Adjustable steel tube joint closing device

An adjustable steel pipe technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of lower production efficiency, uneven stress on steel pipes, and poor pressing effects, etc., and improve the quality of enterprises. Production efficiency, improvement of pressing effect, and effect of improving seaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

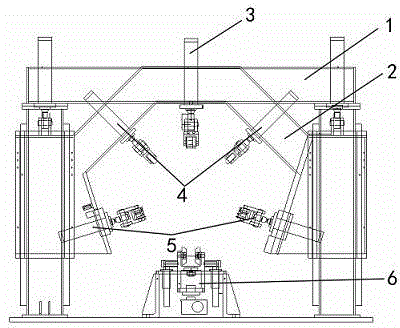

[0036] Such as figure 1 The adjustable seam joining device for steel pipes shown includes a machine base 1, a pressing roller fixing seat 2, a first pressing roller 3, a second pressing roller 4, a third pressing roller 5 and a lifting support 6. The lifting support 6 is placed directly below the fixing seat 2 of the pressing roller.

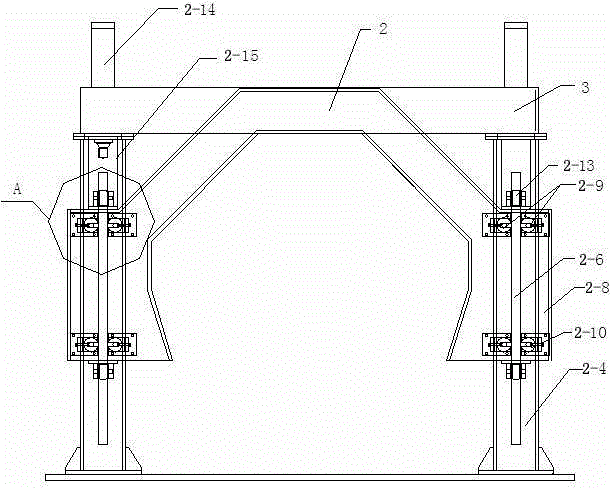

[0037] as attached figure 2 , attached Figure 6 , attached Figure 7 , attached Figure 8 As shown, the base 1 is provided with a pressing roller fixing seat 2, the base 1 includes two sets of vertical pillars and a top frame 2-3, each set of vertical pillars consists of two vertical pillars 2-4, the top frame 2-3 is a rectangular structural frame surrounded by four beams 2-5, and the four vertical pillars 2-4 are respectively fixed on four of the top frame 2-3. On the corner, the inner side of the vertical pillar 2-4 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com