Rapid shoe sole press-fit device for shoe production

A pressing device and fast technology, applied in the direction of footwear, application, and bonding shoe parts, etc., can solve the problems of complex operation, poor pressing effect, and low work efficiency, and achieve simple operation, high work efficiency, and pressing effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

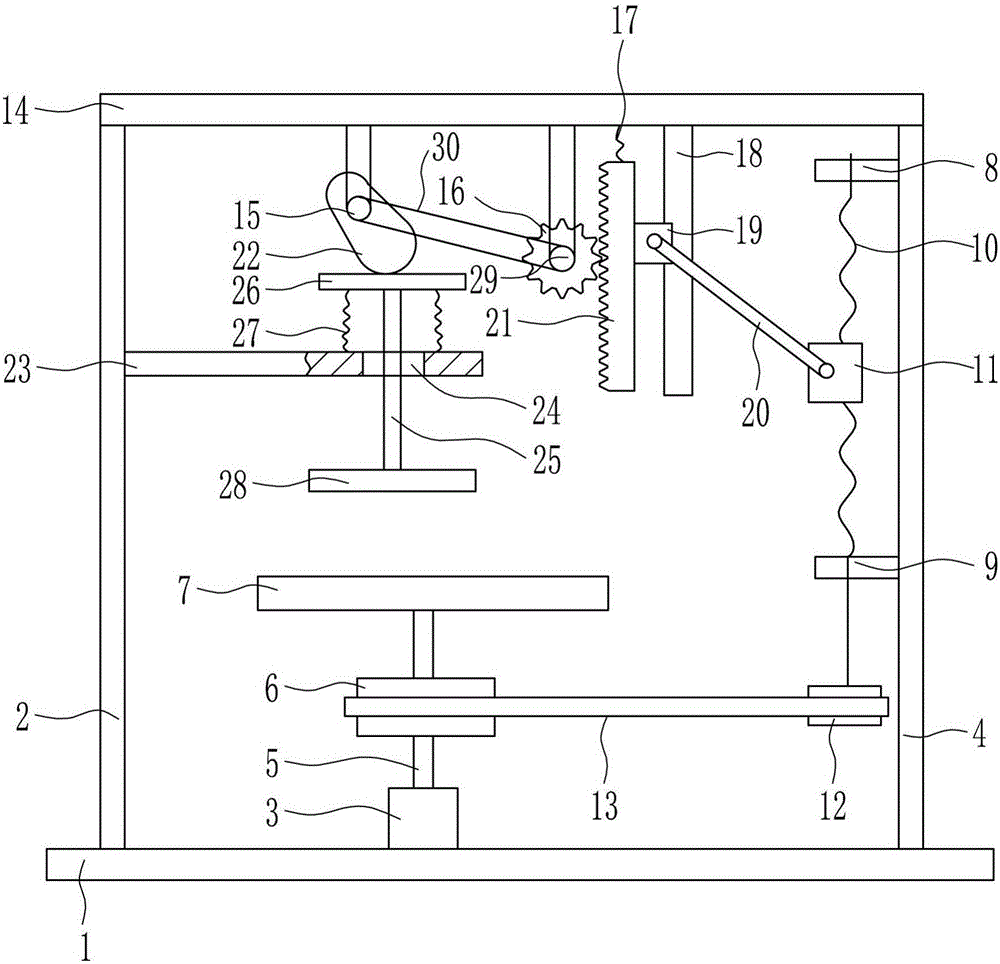

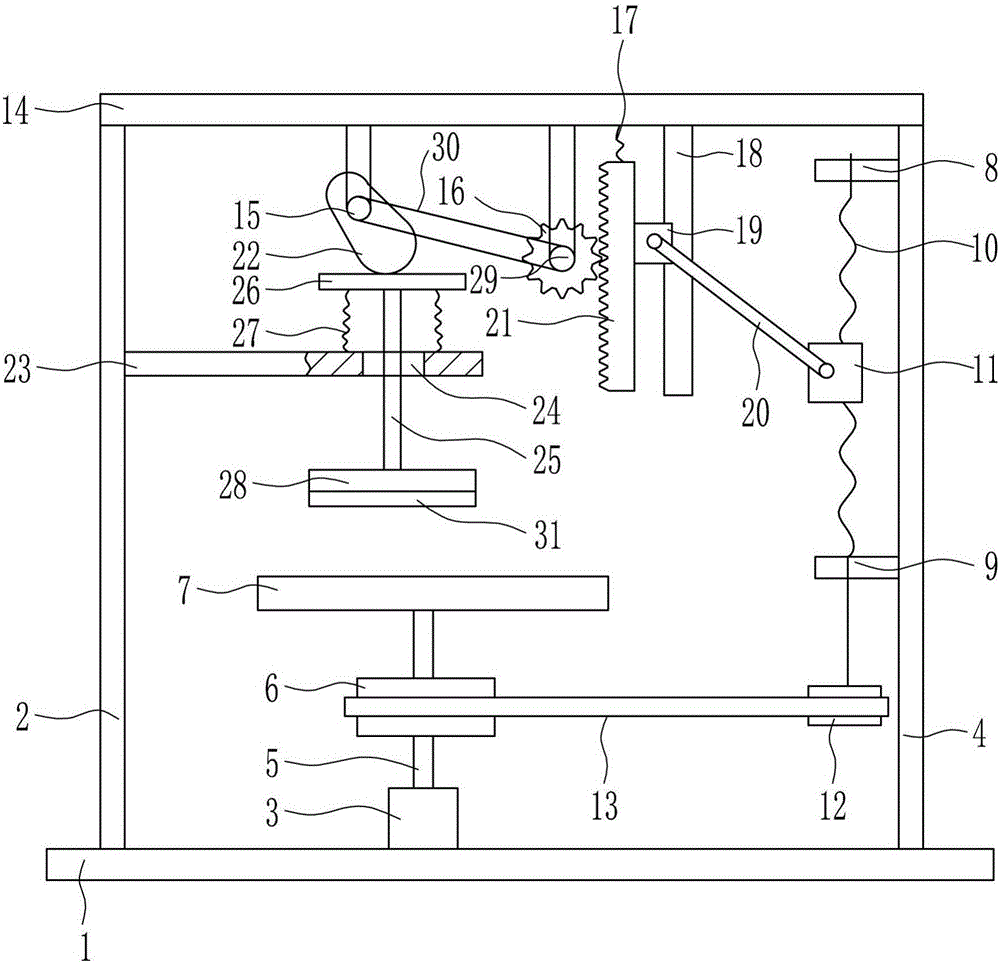

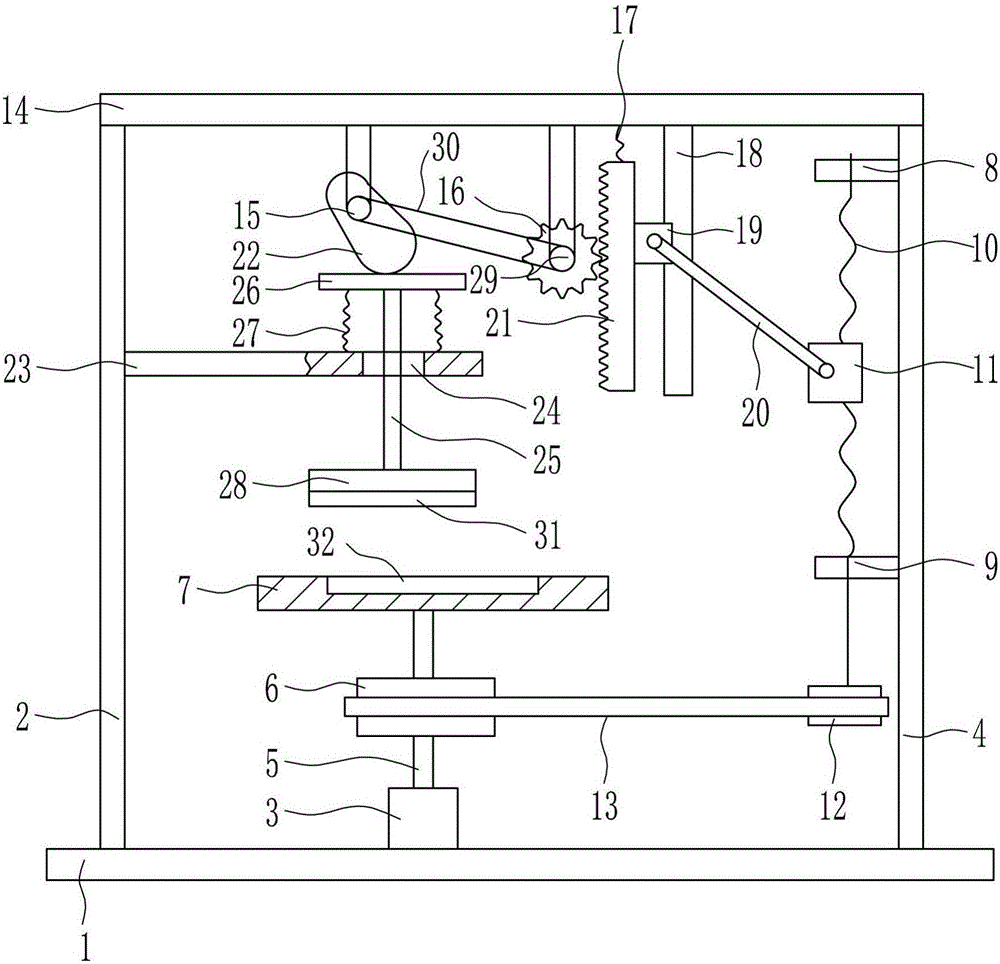

[0026] A shoe sole quick pressing device for shoe production, such as Figure 1-3 As shown, it includes a base plate 1, a left side plate 2, a motor 3, a right side plate 4, a rotating shaft 5, a large pulley 6, a placement plate 7, an upper bearing seat 8, a lower bearing seat 9, a screw rod 10, a nut 11, a small Pulley 12, flat belt 13, top plate 14, driven wheel 15, gear 16, first spring 17, slide rail 18, slider 19, connecting rod 20, rack 21, cam 22, guide plate 23, lifting rod 25, movable Plate 26, second spring 27, briquetting block 28, driving wheel 29 and first belt 30, bottom plate 1 top is provided with left side plate 2, motor 3 and right side plate 4 successively from left to right, on the output shaft of motor 3 Connected with a rotating shaft 5, the middle part of the rotating shaft 5 is provided with a large pulley 6, the top of the rotating shaft 5 is horizontally provided with a placement plate 7, and the left side of the right side plate 4 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com