Pollution prevention and control method in shiitake mushroom cultivation process

A mushroom culture medium and mushroom technology are applied in mushroom cultivation, botanical equipment and methods, cultivation and other directions, and can solve problems such as pollution and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

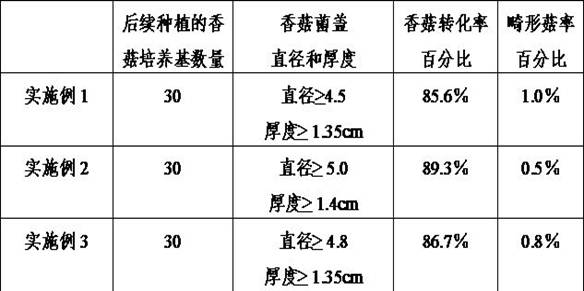

Embodiment 1

[0027] The pollution prevention and control method in the shiitake mushroom cultivation process of this embodiment, concrete prevention and control steps are as follows:

[0028] S1. Preparation of mushroom medium materials: first (by weight) prepare 60 parts of sawdust, 10 parts of locust bean pods, 3 parts of bean coat, 10 parts of corncobs, 5 parts of sweet potato dregs, 3 parts of barley grass, and 10 parts of bean cake dregs and 3 parts of humic acid, crush locust bean pods, corncobs and barley grass through a pulverizer, and stir and mix with sawdust, bean coat, sweet potato residue, bean cake residue, humic acid and water;

[0029] Among them, the sawdust is specifically dry, mildew-free, and impurity-free broad-leaved tree hard miscellaneous wood sawdust;

[0030] The bean coat used is specifically the bean coat with water that falls off after sprouting;

[0031] The addition ratio of each culture medium raw material and water is 1:1.2;

[0032] S2. Lentinus edodes c...

Embodiment 2

[0040] The pollution prevention and control method in the shiitake mushroom cultivation process of this embodiment, concrete prevention and control steps are as follows:

[0041] S1. Preparation of mushroom medium materials: first (by weight) prepare 65 parts of sawdust, 7 parts of locust bean pods, 4 parts of bean coat, 7 parts of corncobs, 7 parts of sweet potato dregs, 4 parts of barley grass, and 7 parts of bean cake dregs and 2 parts of humic acid, crush locust bean pods, corncobs and barley grass through a pulverizer, and stir and mix with sawdust, bean coat, sweet potato residue, bean cake residue, humic acid and water;

[0042] Among them, the sawdust is specifically dry, mildew-free, and impurity-free broad-leaved tree hard miscellaneous wood sawdust;

[0043] The bean coat used is specifically the bean coat with water that falls off after sprouting;

[0044] The addition ratio of each culture medium raw material and water is 1:1.25;

[0045] S2. Lentinus edodes cul...

Embodiment 3

[0053] The pollution prevention and control method in the shiitake mushroom cultivation process of this embodiment, concrete prevention and control steps are as follows:

[0054] S1. Preparation of mushroom medium materials: first (by weight) prepare 70 parts of sawdust, 5 parts of locust bean pods, 5 parts of bean coat, 5 parts of corncobs, 10 parts of sweet potato dregs, 5 parts of barley grass, and 5 parts of bean cake dregs and 1 part of humic acid, crush locust bean pods, corncobs and barley grass through a pulverizer, and stir and mix with sawdust, bean coat, sweet potato residue, bean cake residue, humic acid and water;

[0055] Among them, the sawdust is specifically dry, mildew-free, and impurity-free broad-leaved tree hard miscellaneous wood sawdust;

[0056] The bean coat used is specifically the bean coat with water that falls off after sprouting;

[0057] The ratio of each medium raw material to water is 1:1.3;

[0058] S2. Lentinus edodes culture medium shaping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com