Silk screen cleaning device and method

A cleaning device and screen technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems affecting paper air permeability and cleanliness, affecting paper quality, affecting paper water permeability and cleanliness Degree and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

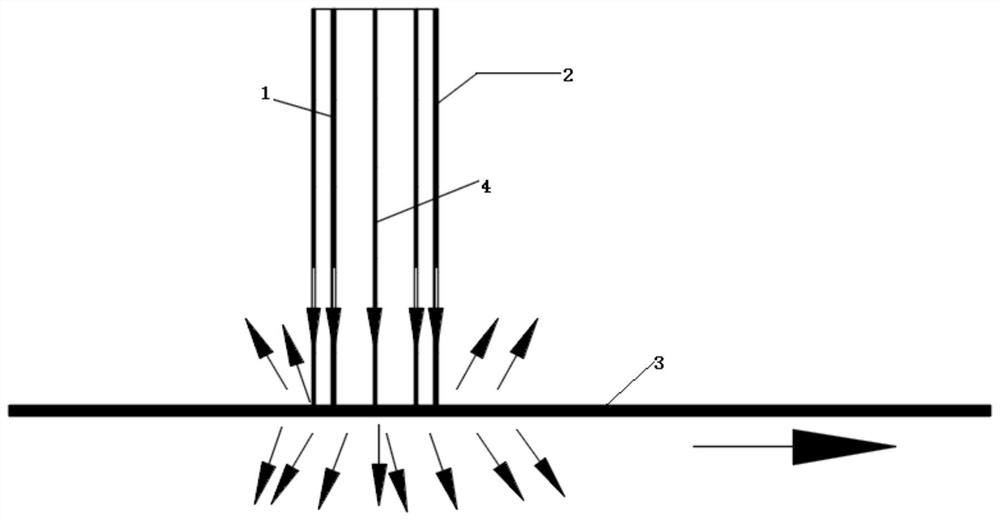

[0080] A screen cleaning device, comprising a main body, the main body is provided with a first group of air knives, the first group of air knives includes a first annular air knife 1, a second annular air knife 1, and a cleaning liquid nozzle, wherein the first annular The air knife 1 is surrounded by the second annular air knife 2 and the cleaning liquid nozzle is surrounded by the first annular air knife 1 .

[0081] The cleaning liquid nozzle can be arranged in any shape of inline, cross, *, #, polygon, and ring. But preferably, the cleaning liquid nozzle in the above example is the high-pressure water needle 4 . The main body is provided with a cleaning liquid pipeline, and the cleaning liquid pipeline passes through the main body and communicates with the high-pressure water needle 4 .

[0082] The first annular gas knife 1 includes a first gas channel and a first gas outlet, the first gas outlet is located on the surface of the main body, the first gas channel communic...

Embodiment 2

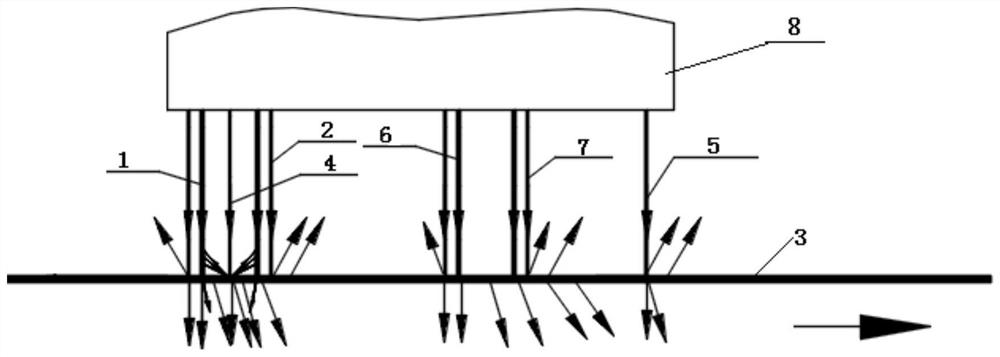

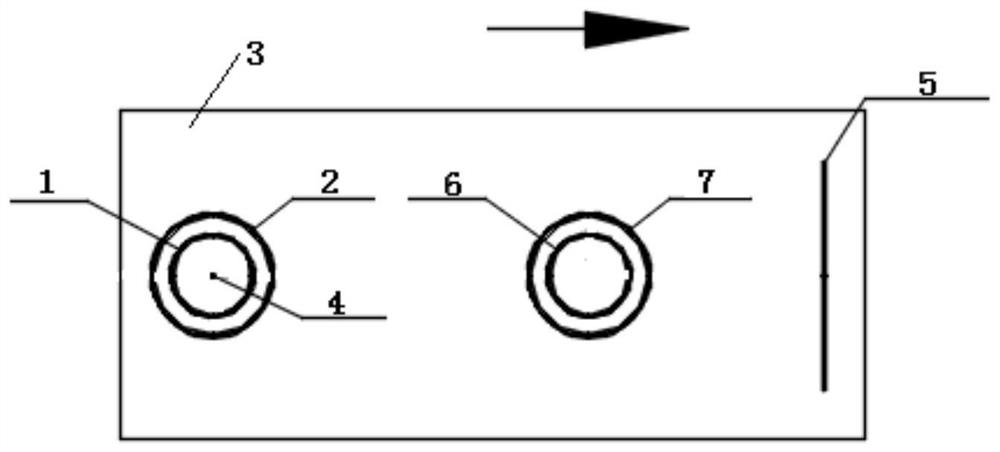

[0093] Based on the first embodiment above, this embodiment adds a second group of air knives, specifically, a second group of air knives is also provided in the main body 8, and the second group of air knives is located downstream of the first group of air knives, wherein, The second group of air knives includes a third annular air knife 6 and a fourth annular air knife 7 , wherein the third annular air knife 6 is surrounded by the fourth annular air knife 7 .

[0094] The third annular gas knife 6 includes a third gas channel and a third gas outlet, the third gas outlet is located on the surface of the main body, the third gas channel communicates with the third gas outlet through the main body; The knife 7 includes a fourth gas channel and a fourth gas outlet, the fourth gas outlet is located on the surface of the main body, and the fourth gas channel communicates with the fourth gas outlet through the main body.

[0095] Similarly, the third gas channel and the fourth gas ...

Embodiment 3

[0101] Preferably, on the basis of Embodiments 1 and 2, a third group of air knives is also provided in the main body 8, and the third group of air knives is located downstream of the second group of air knives, wherein the third group of air knives includes Fifth air knife 5.

[0102] The working process is as follows:

[0103] Such as Figure 2-3 As shown, the air intake pipe of the fifth air knife 5 is connected with the air supply equipment outside the main body 8, and the gas enters the air intake pipe and sends the gas to the fifth air outlet through the fifth exhaust pipe arranged in a ring, and the gas forms the fifth air outlet. The air knife 5 sweeps the surface of the screen 3;

[0104] Referring to Embodiment 1 and Embodiment 2, the area after the initial cleaning of the screen by the first set of air knives moves to the bottom of the second set of air knives for further blowing and drying.

[0105] After the screen 3 leaves the second set of air knives, it move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com