Diaphragm for battery and preparation method thereof

A separator and battery technology, applied in the field of battery separators and their preparation, can solve problems such as poor bonding performance, and achieve the effects of improving rate discharge and cycle performance, excellent bonding performance, and improving cell hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The preparation method of PVDF and PMMA mixed slurry comprises the following steps:

[0064] Add 25-35 parts of PVDF and 8-16 parts of dispersant to 170-190 parts of water, mix and stir for 110-130 minutes to disperse evenly, then add 110-130 parts of PMMA solution and stir for 30-40 minutes, then add 7-15 parts Thickener, 3-10 parts of defoamer and 18-25 parts of binder are stirred evenly to obtain mixed slurry of PVDF and PMMA.

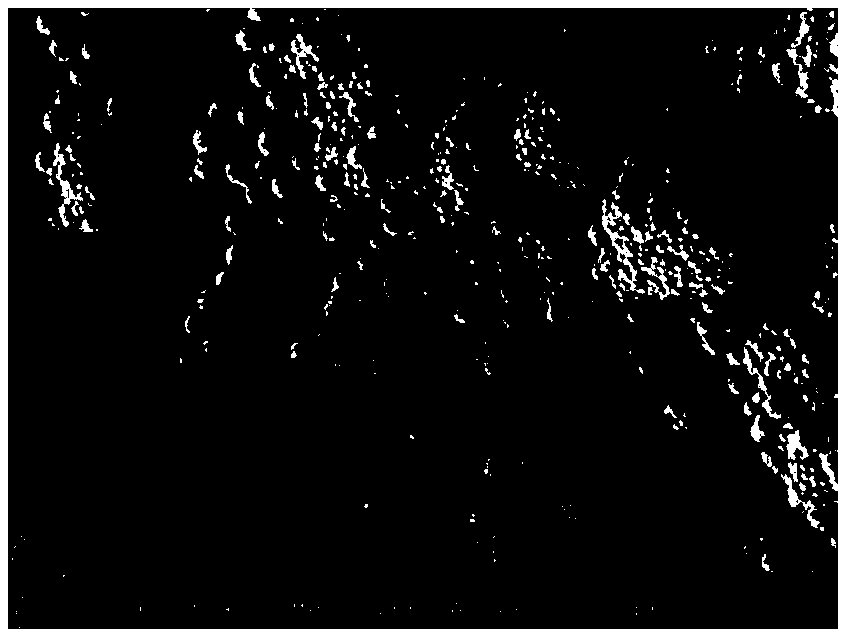

[0065] Depend on figure 1 It can be seen that the particle size of PVDF pellets is 100-200nm, and the particle size of PMMA pellets is 500-600nm. PVDF and PMMA are mixed well, and the battery separator prepared after spraying has good adhesion, which is conducive to improving the adhesion with the battery pole piece. Excellent adhesion, reduce interface resistance.

[0066] Preferably, the base film includes at least one of a polypropylene base film, a polyethylene base film, a polyimide base film and a polyester non-woven fabric base film....

Embodiment 1

[0097] A separator for a battery, comprising a polyethylene base film, an aramid fiber coating and a mixed coating of PVDF and PMMA connected in sequence.

[0098] The preparation method of the separator for the battery comprises the following steps:

[0099] (a) Take 15 parts of aramid fiber, 15 parts of aluminum oxide, 12 parts of ethyl cellulose and 13 parts of dimethylacetamide, heat and stir to dissolve, the dissolution temperature is 80 ℃, and mix evenly to obtain aramid fiber slurry; The 9um polyethylene-based membrane is coated with aramid fiber slurry by oil system and subjected to extraction process, the coating thickness is 3um, and dried in an oven at 50°C for 2.5min to obtain an aramid fiber coated separator;

[0100] (b) Add 32 parts of PVDF and 10 parts of sodium polyethylene glycol alkyl aryl ether sulfonate to 175 parts of water, mix and stir for 120 minutes to make it uniformly dispersed, then add 125 parts of PMMA solution and stir for 30 minutes, then add 9...

Embodiment 2

[0102] A separator for a battery, comprising a polyethylene base film, an aramid fiber coating and a mixed coating of PVDF and PMMA connected in sequence.

[0103] The preparation method of the separator for the battery comprises the following steps:

[0104] (a) Take 25 parts of aramid fiber, 8 parts of aluminum oxide, 20 parts of dimethyl carbonate and 15 parts of N-methylpyrrolidone, heat and stir to dissolve, the dissolution temperature is 80 ℃, and mix well to obtain aramid fiber slurry; The 9um polyethylene-based membrane is coated with aramid fiber slurry by oil system and subjected to extraction process, the coating thickness is 3um, and dried in an oven at 60°C for 2 minutes to obtain an aramid fiber coated separator;

[0105](b) Add 28 parts of PVDF and 14 parts of alkylphenol polyvinyl ether to 185 parts of water, mix and stir for 120 minutes to disperse evenly, then add 118 parts of PMMA solution and stir for 30 minutes, then add 13 parts of polyethylene glycol, 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com