Surface treatment technology of singeing and calendering integrated machine

A technology of singeing calendering and surface treatment, which is applied in the direction of singeing, fabric surface trimming, textiles and papermaking, etc. It can solve the problems of increased production time, retention of filter materials, and inability to coordinate the speed of online operation, so as to improve utilization Efficiency, the effect of expanding market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

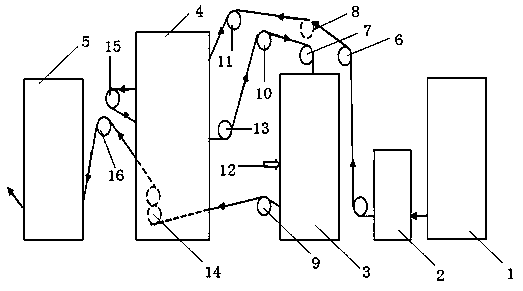

[0015] Such as figure 1 As shown, a surface treatment process of a singeing and calendering integrated machine includes the following steps: pass the filter material to be treated through the front cloth storage rack 1 and the bristle box 2, through the cloth guide roller 1 (6), the cloth guide roller 3 (8) Enter the calender unit 4 with the bridge upper roll 11, pass through the gap between the upper press roll and the hot roll in the calender unit 4, enter the calender unit again through the rear expansion roll 15, and pass through the front expansion unit in turn Roller 13, connecting bridge middle roller 10 and fabric guide roller 2 (7) enter singeing unit 3, and then pass through connecting bridge lower roller 9, traction roller 14, cooling roller 16, and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com