Preparation method for water-repelling grease-proofing easy-ash-removal filter material

A technology of water and oil repellency and filter material, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc. It can solve the problems of impregnation in finishing process, inability to adapt to oil, and water is easy to paste bags, etc., to achieve uniform distribution and increased degree of freedom , The effect of simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example one

[0020] Filter material used: non-alkali glass fiber twill woven fabric, product standard specification model: GE·W·T-400-h-o.

[0021] Preparation of dipping emulsion: Place the dipping liquid in the dipping tank according to the proportions in Table 1, and stir fully under normal temperature and pressure to make it uniform.

[0022] Table 1 The proportion of GE·W·T-400-h-o impregnation solution

[0023] Ingredients formula

[0024] Finishing process: immerse the element filter material in sequence --- tentering and finalizing --- drying. Oven temperature: pre-baking at 160℃, baking at 210℃, and it takes 15min to move cloth at a constant speed.

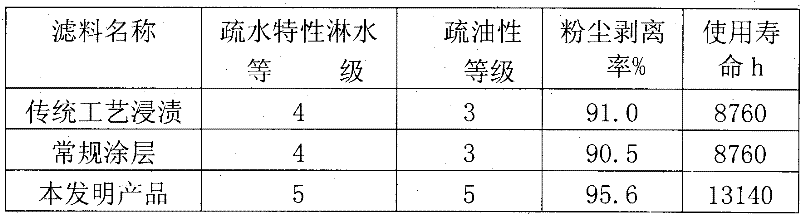

[0025] Technical indicators: See Table 2 for the technical indicators of the filter material's water-repellent, oil-repellent and easy-cleaning effect and the comparison with the traditional process.

[0026] Table 2 Comparison of technical indexes of GE·W·T-400-h-o this invention and traditional technology

[0027]

Example Embodiment

[0028] Example two

[0029] Filter material used: polyester needle felt, product standard specification model: PET·NW-500-h-o.

[0030] Preparation of dipping emulsion: Place the dipping solution in the dipping tank according to the proportions in Table 3, and fully stir it under normal temperature and pressure to make it uniform.

[0031] Table 3 The proportion of PET·NW-500-h-o impregnation solution

[0032] Ingredients formula

[0033] Finishing process: immerse the element filter material in sequence --- tentering and finalizing --- drying. Oven temperature: pre-baking at 105°C, baking at 125°C, and it takes 15 minutes to move cloth at a constant speed. The hot pressing temperature is 135℃.

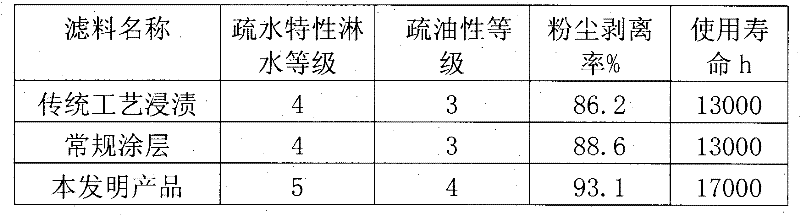

[0034] Technical indicators: See Table 4 for the technical indicators of the filter material of the present invention for its water repellent, oil-repellent and easy-cleaning effect and the comparison table with the traditional process.

[0035] Table 4 Comparison of technical indicators of...

Example Embodiment

[0037] Example three

[0038] Filter material used: polyphenylene sulfide and polyimide blended needle felt, product standard specification model: PPS+P84·NW·PPS-500-h-o.

[0039] Preparation of dipping emulsion: Place the dipping solution in the dipping tank according to the proportions in Table 5, and fully stir it under normal temperature and pressure to make it uniform.

[0040] Table 5 PPS+P84·NW·PPS-500-h-o impregnating liquid ratio

[0041] Ingredients formula

[0042] Finishing process: immerse the element filter material in sequence --- tentering and finalizing --- drying. Oven temperature: Pre-baking at 130°C, baking at 150°C, and it takes 16 minutes to move cloth at a uniform speed. The hot pressing temperature is 170°C.

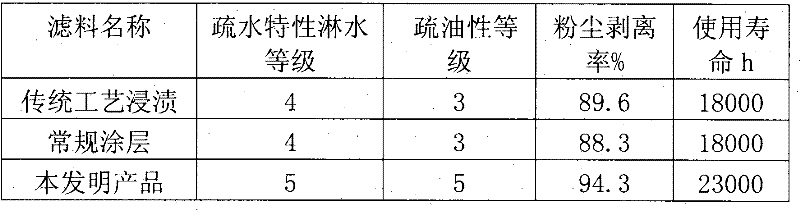

[0043] Technical indicators: See Table 6 for the technical indicators of the filter material's water-repellent, oil-repellent and easy-cleaning effect and the comparison with the traditional process.

[0044] Table 6 PPS+P84·NW·PPS-500-h-o Comparison of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com