Method for cleaning and regenerating filter belt

A filter belt and filter part technology, applied in the field of cleaning, can solve the problems such as the decrease of the air permeability of the filter belt, the influence of the dehydration efficiency of the filter belt, the inability to clean the filter belt or the polyester mesh, etc., and achieve the reduction of waste water discharge and good dehydration effect. , the effect of good environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

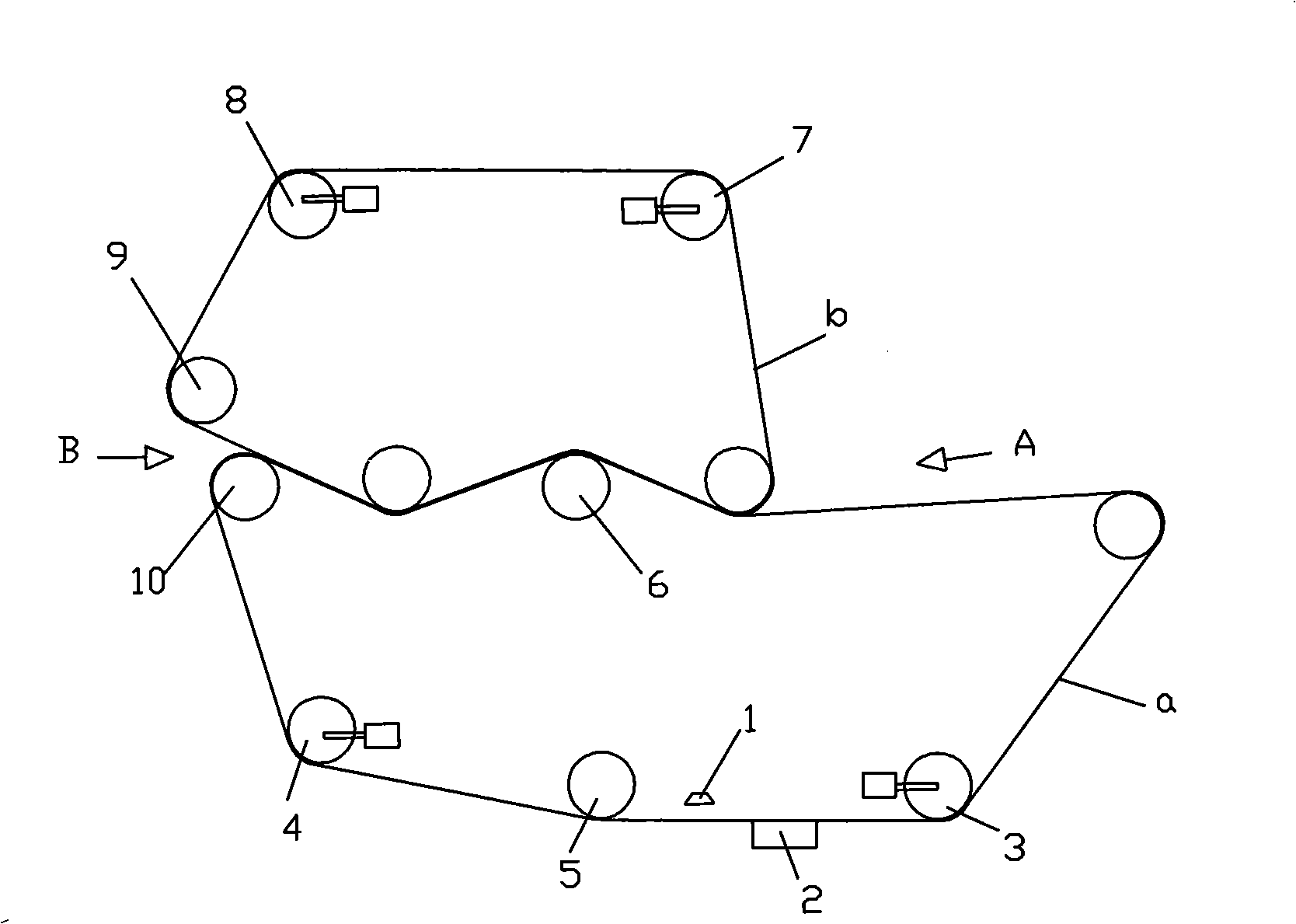

[0014] The cleaning and regenerating method of the filter belt is a vacuum cleaning and regenerating method, comprising a water spray cleaning step and a vacuum suction cleaning step, wherein the water spray cleaning is performed first, and then the vacuum suction cleaning is performed. The water spray cleaning step is to carry out water spray cleaning to the filter belt through the water spray device 1, and the water spray device 1 is arranged at the discharge port B of the press filter part of the belt filter press; the vacuum suction cleaning step The vacuum suction device 2 is used to carry out vacuum suction cleaning on the filter belt. The vacuum suction device 2 is installed at the discharge port B of the press filter part of the belt filter press, and the water spray device 1 is installed on the vacuum suction Device 2 front. In this cleaning and regeneration method, before vacuum suction cleaning, the filter belt is pre-cleaned with water spray, so that there is suffi...

Embodiment 2

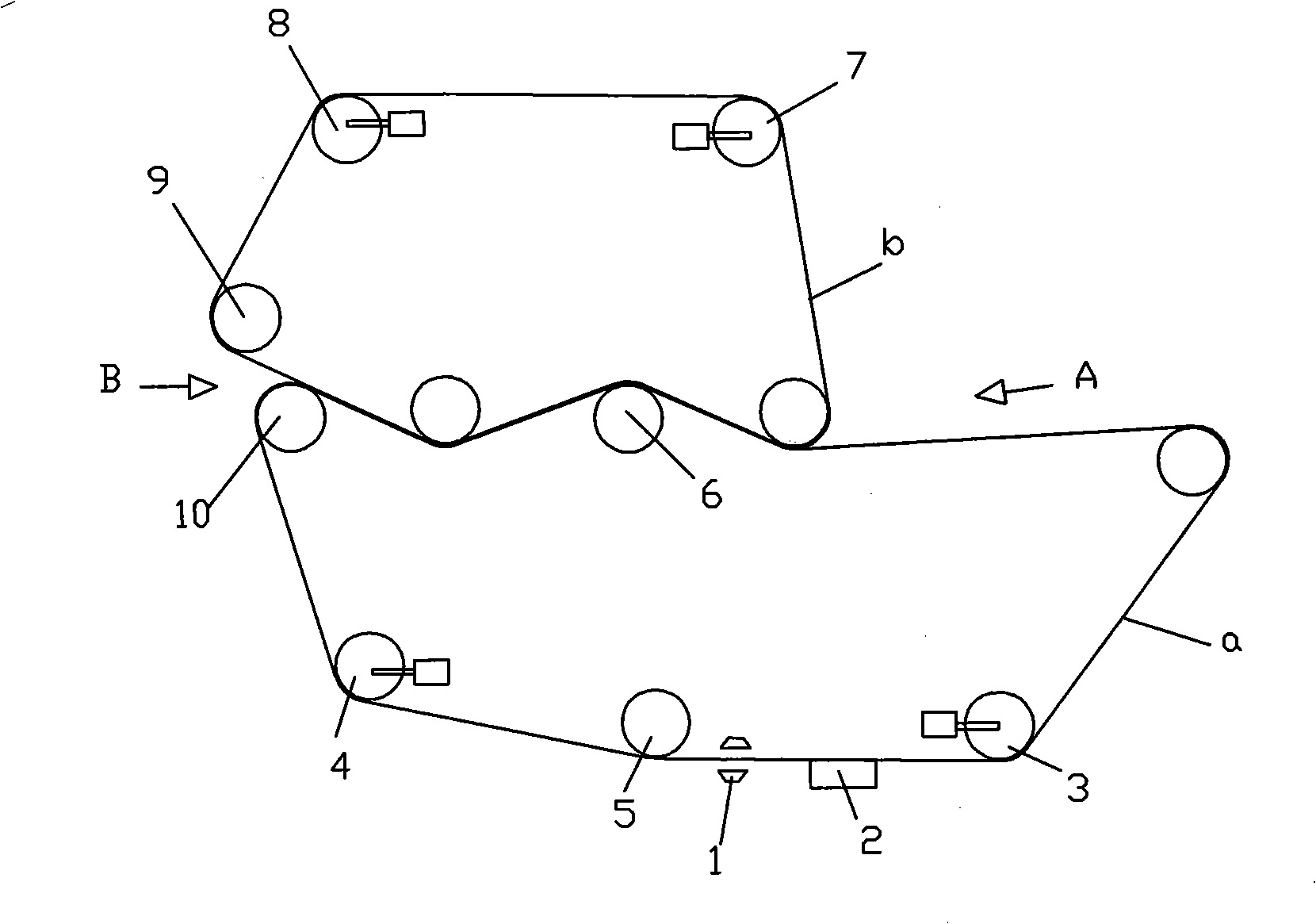

[0019] The water spray cleaning step of the filter belt cleaning and regeneration method adopts the method of double-sided spraying, and the cleaning water is sprayed on both sides of the lower filter belt a; the vacuum degree of the vacuum suction device 2 is 0.025MPa. see figure 2 , the water spraying device 1 of the present embodiment uses two groups of shower nozzles, and water is installed on and below the lower filter belt a after the two filter belts are separated after the discharge port B of the press filter part of the belt filter press is discharged. The shower head of the shower device 1, the water shower device 1 is installed in the front of the vacuum suction device 2. When in use, the cleaning water in the water spray cleaning step sprays the upper and lower sides of the lower filter belt a.

[0020] The other steps and the device used in the cleaning and regeneration method of this embodiment are the same as those in Embodiment 1.

[0021] Spraying on both s...

Embodiment 3

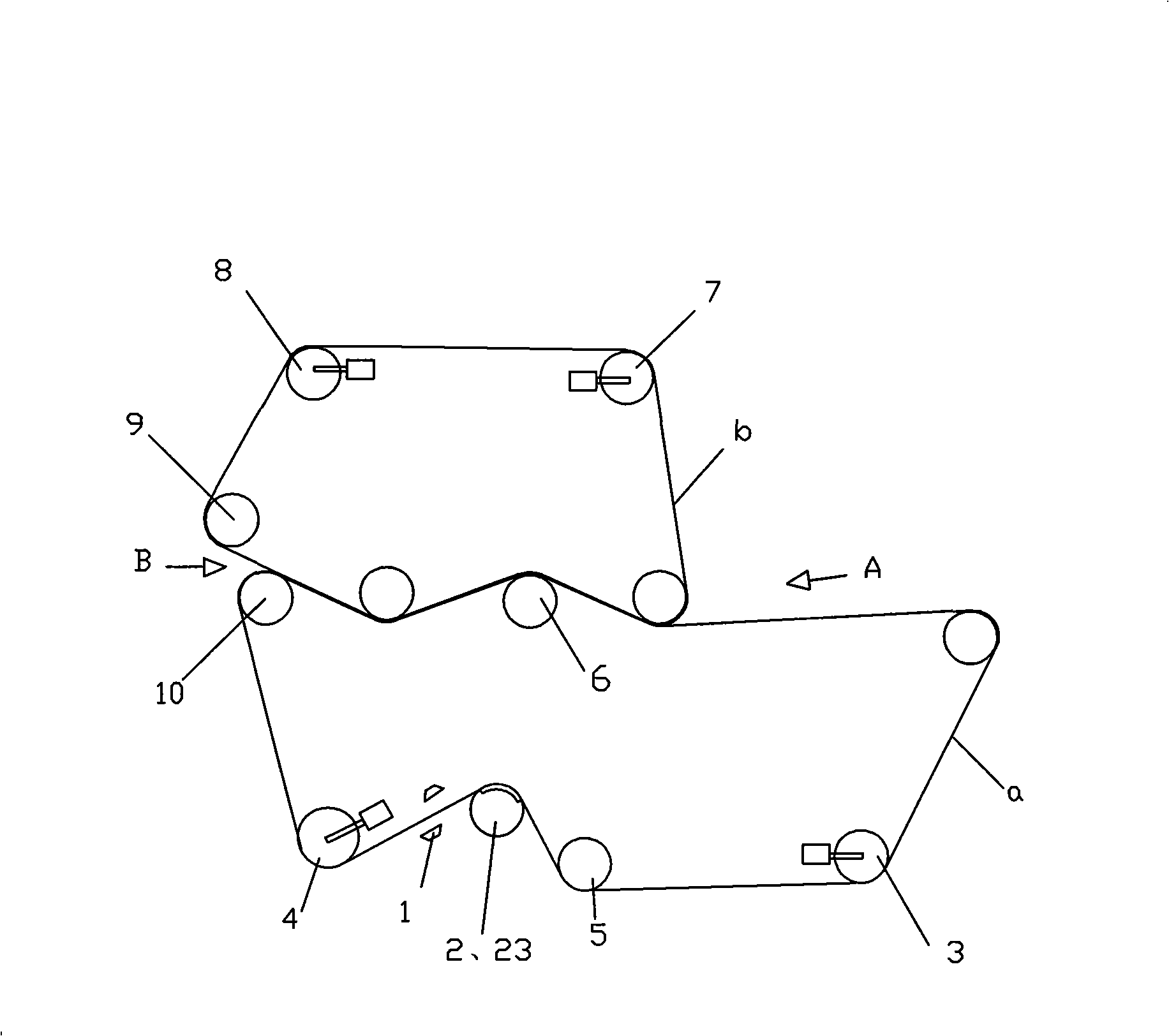

[0024] The vacuum suction device 2 used in the vacuum suction cleaning step of the filter belt cleaning regeneration method is mainly composed of a vacuum pump, a valve and a vacuum suction roller 23, and the vacuum degree of the vacuum suction device 2 is 0.04MPa. see image 3 , The vacuum suction roller 23 is installed close to the lower filter belt a. After the lower filter belt a is unloaded at the outlet B of the press filter part, after being sprayed by two groups of nozzles of the water spray device 1, it enters the position corresponding to the vacuum suction roller 23 for vacuum suction cleaning. Vacuum suction roller 23 is commonly used known product, and its roller surface has the suction hole of leading vacuum pump.

[0025] The other steps of the cleaning and regeneration method in this embodiment and the devices used are the same as those in Embodiment 2.

[0026] This embodiment is used for cleaning regeneration air permeability is 50 liters / meter 2 ·The filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com