Automatic printing paper waste discharging device

A technology of automatic discharge and paper waste, applied in the field of papermaking, can solve the problems that the sundries cannot be cleaned in time, the dust cannot be completely separated, and it is unfavorable for long-term use, etc., and achieves the effect of ensuring air passage, low use cost, and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

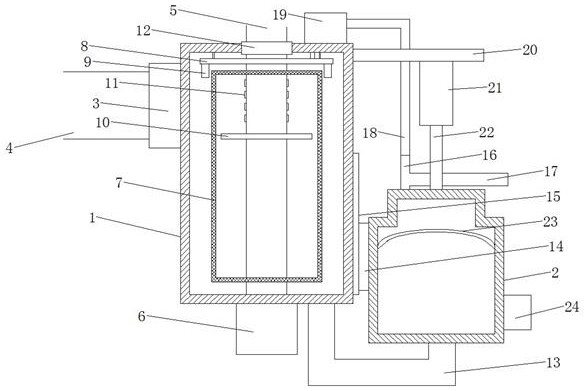

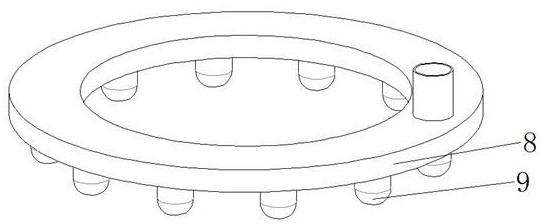

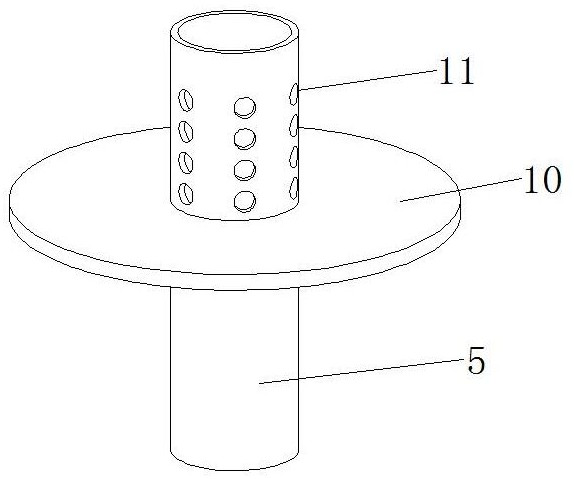

[0020] Please refer to the figure, in the embodiment of the present invention, an automatic printing paper waste discharge device includes a housing 1, a water tank 2, a suction fan 3, an air inlet pipe 4, and an air outlet pipe 5; on the top of the housing 1 It is connected with an air intake pipe 4, and a material suction fan 3 is installed in the air intake pipe 4, and the air with waste is sucked into the housing 1; the bottom of the housing 1 is coaxially fixed with a vertical motor 6, and the motor The output shaft of 6 extends upwards into the housing 1, and the output shaft of the motor 6 is coaxially fixed with a vertical air outlet pipe 5, and the upper end of the air outlet pipe 5 stretches out from the top of the housing 1, and The bearing 12 is rotatably connected with the casing 1 , so that the filtered air is discharged upward from the top of the air outlet pipe 5 .

[0021] Inside the housing 1, there is a separation mesh cylinder 7 fixed on the outside of the ...

Embodiment 2

[0024] On the basis of Embodiment 1, the top of the water tank 2 is communicated with a three-way pipe 16, and one end of the three-way pipe 16 is communicated with an overflow pipe 17 that is flush with the top of the water tank 2. When the water tank 2 moves downward, the excess The water is discharged from the water tank 2, and the other end of the tee pipe 16 is connected to the circulation pump 19 through the circulation pipe 18. The material of the circulation pipe 18 is the same as that of the drain pipe 13. A part of the water inside is pumped into the water spray pipe 8, so that a part of the water circulates and flows, reducing the consumption of water.

[0025] During use, the air with waste enters into the housing 1 from the air intake pipe 4, contacts with the rotating separation net cylinder 7, and after being filtered by the separation net cylinder 7, the air enters from the air inlet hole 11 in the separation net cylinder 7. Exhausted from the air outlet pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com