Method for preparing tobacco sheet paper base from tobacco stems

A technology for making tobacco sheets and tobacco stems, applied in the directions of preparing tobacco, tobacco, and application, can solve problems such as changing the performance and quality of paper bases of tobacco sheets, and achieve the effects of improved paper base performance, excellent paper-forming properties, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

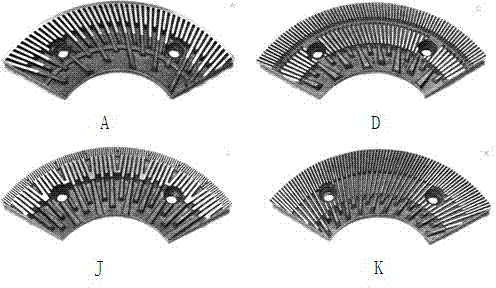

Image

Examples

Embodiment 1

[0029] 1. Experimental raw materials: The tobacco stems used in the experiment were provided by Guangdong China Tobacco Industry Co., Ltd. The tobacco stems obtained after conventional threshing and re-roasting were taken back, refrigerated at 4°C, and packed in bags to balance the moisture for later use.

[0030]2. Dipping and extraction: the extraction of tobacco stems can refer to existing routines. The single-stage immersion extraction experiment of tobacco stems in this example is carried out in a digital display constant temperature water bath (Jinyi HHS digital display constant temperature water bath can be used, or other similar water baths can be used). First put the tobacco stems into a polyethylene sealed bag, add a certain volume of distilled water (liquid ratio 1:7) according to the experimental conditions, and put it in a water bath that has been raised to 60°C, and keep it warm for 100 minutes. During the immersion extraction, rub it every 10 minutes to make the...

Embodiment 2

[0076] 1. Raw materials: Tobacco stems used in the experiment were provided by Guangdong China Tobacco Industry Co., Ltd. The tobacco stems obtained after conventional threshing and re-roasting were taken back and refrigerated at 4°C, and packed into bags to balance the moisture for later use.

[0077] 2. Experimental method

[0078] (1) Dipping extraction: The experimental conditions for the steeping and extraction of tobacco stems are as follows: liquid ratio 1:7, temperature 60°C, time 100 min. The single-stage dipping and extraction experiment of tobacco stems was carried out in a conventional experimental electric cooking pot (common type) ZT1-00 / 15L (produced by Xingping Zhongtong Experimental Equipment Co., Ltd.). The amount of tobacco stems in the pot is 1500 g. First, the extraction water calculated according to the liquid ratio is added to the cooking pot to preheat to the specified temperature, then the tobacco stems are added, the pot is covered, and the pot is rot...

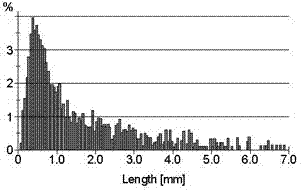

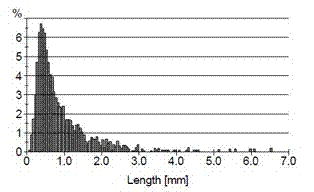

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com