Knitted fabric and production method thereof

A technology for knitted fabrics and production methods, applied in knitting, weft knitting, warp knitting, etc., which can solve the problems of poor functionality such as quick drying of fabrics and increased production costs, so as to ensure bulkiness, light weight, and good softness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

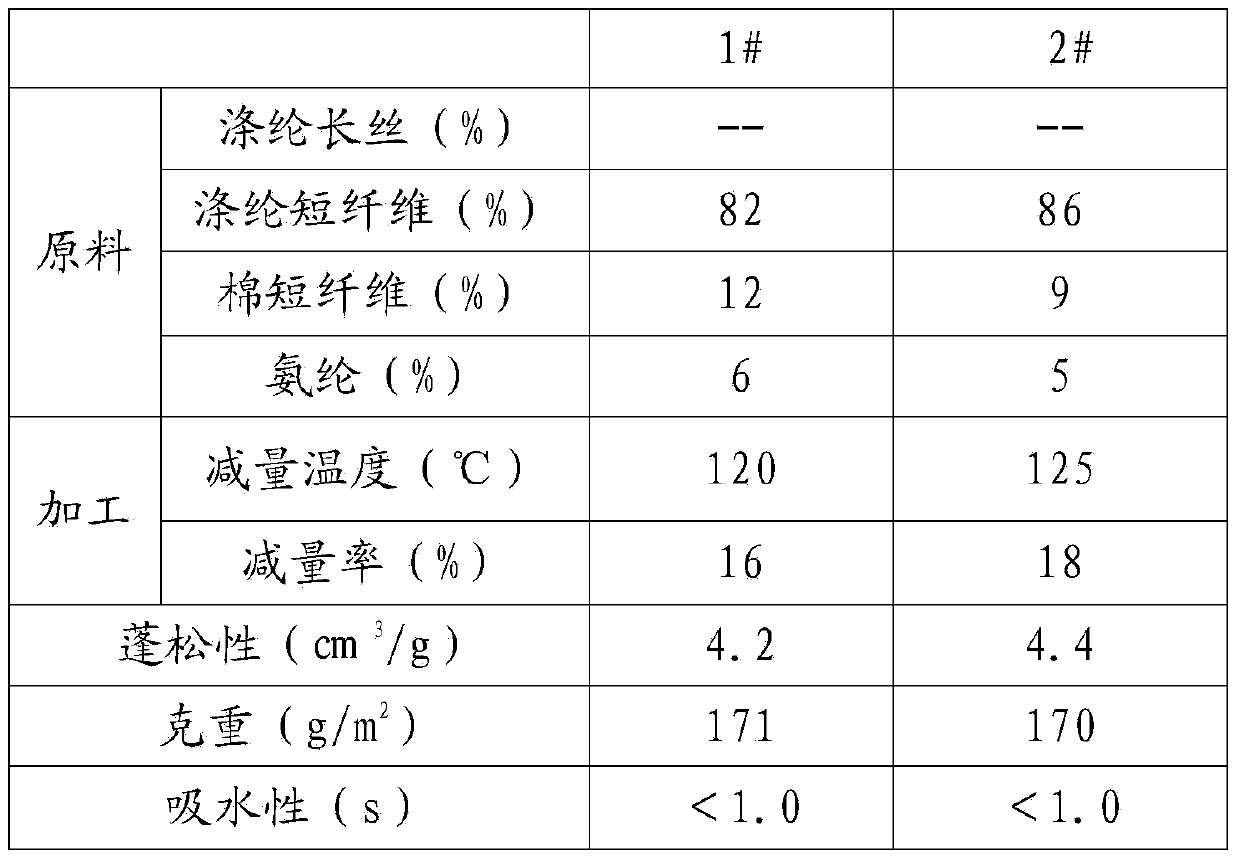

[0028] 1# knitted fabric

[0029] 40s pure polyester spun yarn, 40s cotton spun yarn, and 22dtex spandex are used for weaving, and the proportions of the three yarns are 82%, 12%, and 6% respectively; the grammage of the gray fabric obtained is 200g / m 2 .

[0030] The above-mentioned gray cloth goes through presetting→refining→alkali weight reduction→dyeing→finishing and setting→cloth inspection to finally get the finished product.

[0031] The weight of the finished product is 171g / m 2 .

[0032] Description of process conditions:

[0033] Pre-forming: temperature 190℃*1.2min, overfeed rate 40%;

[0034] Refining: Refining in the bath in the dyeing vat, the refining temperature is 80℃*20min;

[0035] Alkali reduction: reduce the amount in the dye vat, the reduction temperature is 120°C, and the NaOH (30%) is 27g / l.

[0036] The reduction rate is 16%;

[0037] Finishing and shaping: use polyester water-absorbing soft resin with an amount of 30g / l. The setting temperatu...

Embodiment 2

[0039] 2# knitted fabric

[0040] 40s pure polyester spun yarn, 40s polyester-cotton spun yarn, and 22dtex spandex are used for weaving, and the proportions of the three yarns are 86%, 9%, and 5% respectively; the grammage of the gray fabric obtained is 201g / m 2 .

[0041] The above-mentioned gray cloth goes through presetting→refining→alkali weight reduction→dyeing→finishing and setting→cloth inspection to finally get the finished product.

[0042] The weight of the finished product is 170g / m 2 .

[0043] Description of process conditions:

[0044] Pre-forming: temperature 190℃*1.2min, overfeed rate 35%;

[0045] Refining: Refining in the bath in the dyeing vat, the refining temperature is 80℃*20min;

[0046] Alkali reduction: use the reduction in the dyeing vat, the reduction temperature is 125°C, NaOH (30%) is 32g / l,

[0047] The reduction rate is 18%;

[0048]Finishing and shaping: use polyester water-absorbing soft resin with an amount of 25g / l. The setting temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com