No-baffle high-temperature-resistant air filter paper and preparation method thereof

A technology of air filter paper and high temperature resistance, which is applied in the direction of filter paper, separation methods, chemical instruments and methods, etc. It can solve the problems of powder shedding, high resistance of filter paper, high resistance of filter, etc., and achieve enhanced tensile strength and good high temperature resistance. , the effect of high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Please combine figure 1 , in the present embodiment, as the glass fiber air filter paper 1 of filtering base layer, two kinds of borosilicate glass microfibers are used as main raw materials, mixed with alkali-free continuous glass fiber chopped strands with a diameter of 6 μm, fiber lengths of 6 mm and 9 mm, and 1.5 : 1 mixed polyester and aramid organic fibers are made into slurry, stirred and mixed evenly by a high-frequency deflagging machine, after the forming net is vacuum-molded, water-soluble epoxy resin emulsion (Yixing Haotian Chemical Co., Ltd. Company, SM600-WY-35) and water-soluble silicone resin emulsion (Dow Corning Company Z-6018) were mixed according to 1.5:2.5, and diluted 10 times with water, and the diluted emulsion was evenly sprayed on the sizing part and vacuum sucked, and then Dry in a steam dryer at 150°C for 2 to 3 minutes.

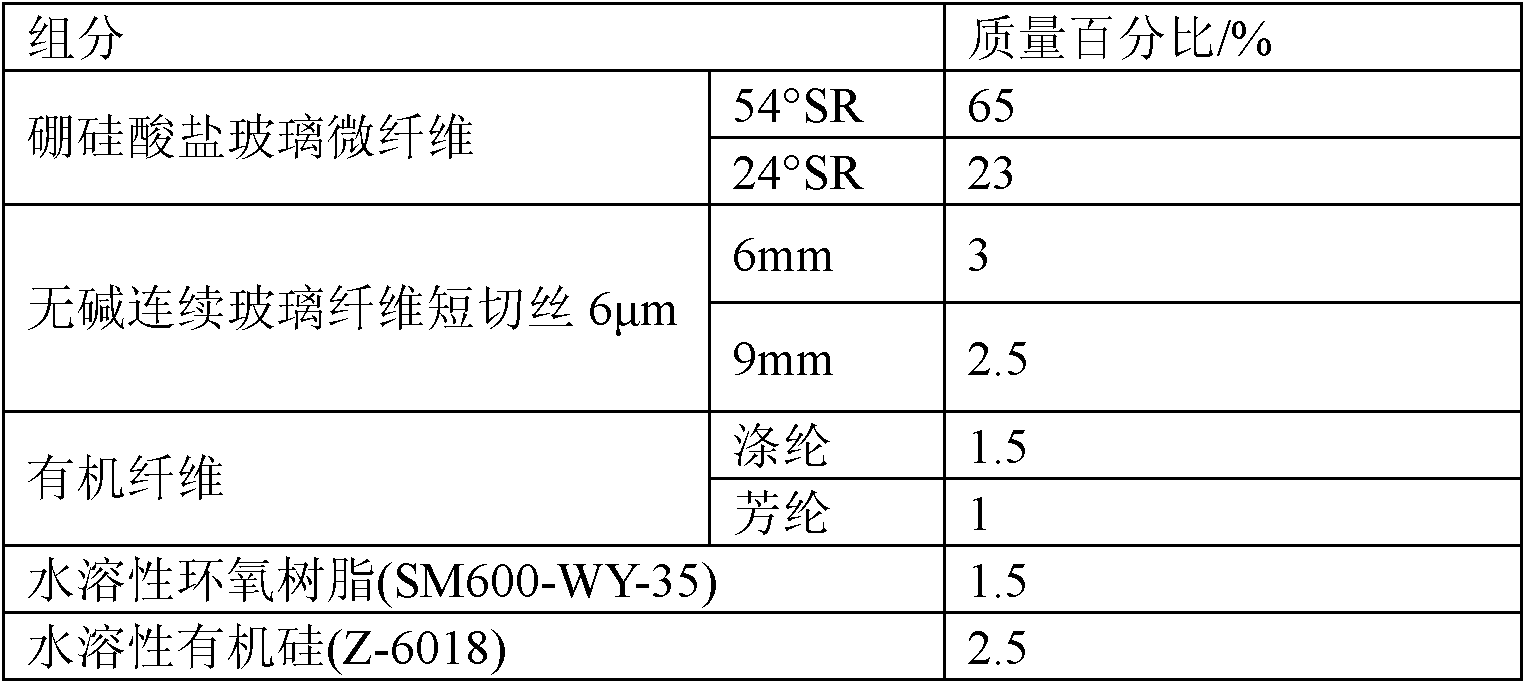

[0019] The mass percentages of each component in the above-mentioned high-temperature-resistant glass fiber air filter ...

Embodiment 2

[0027] In this embodiment, as the glass fiber air filter paper 1 of the filter base layer, two kinds of borosilicate glass microfibers are used as the main raw material, mixed with alkali-free continuous glass fiber chopped strands with a diameter of 6 μm and a fiber length of 6 mm, and organic fiber aromatics. The slurry is made of lentil short-cut fiber, and it is stirred and mixed evenly by a high-frequency debulking machine. After the forming net is vacuum-molded, the water-soluble phenolic resin (phenolic resin for glass fiber produced by Wuxi Xinming Chemical Co., Ltd. ) and water-based silicone emulsion (Dow Corning Z-6018) were mixed at a ratio of 3:1, diluted 10 times with water, sprayed the diluted emulsion evenly on the sizing part and vacuum sucked, and then dried in a steam dryer at 150 ° C for 2 ~3min.

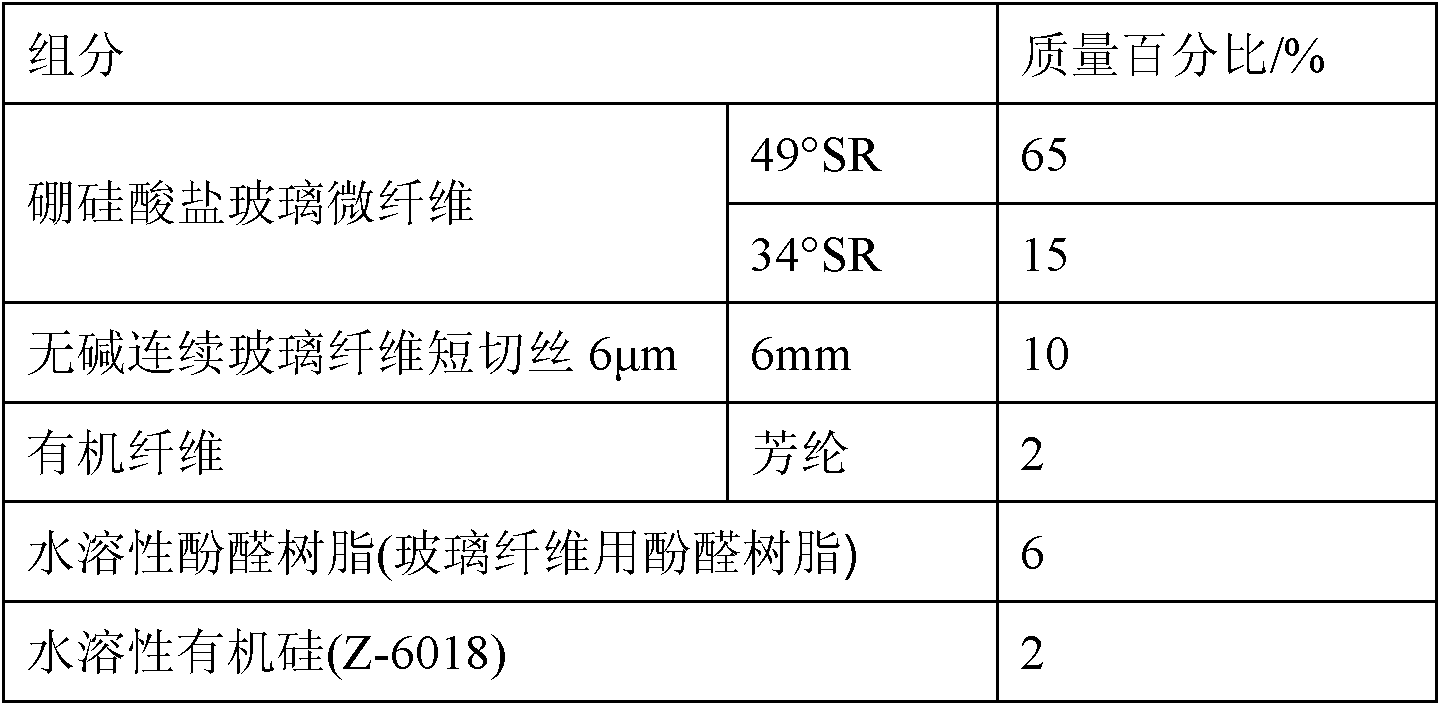

[0028] The mass percent of each component in the above-mentioned high temperature resistant glass fiber air filter paper is shown in Table 3:

[0029] Table 3: ...

Embodiment 3

[0036] In this embodiment, as the glass fiber air filter paper 1 of the filter base, two kinds of borosilicate glass microfibers are used as the main raw material, mixed with alkali-free continuous glass fiber chopped strands with a diameter of 6 μm and a fiber length of 6 mm to make a slurry, Stir and mix evenly with a high-frequency decomposer, and after the forming net is vacuum-molded, dilute the water-based phenolic resin (phenolic resin for glass fiber produced by Wuxi Xinming Chemical Co., Ltd.) with water 20 times in the batching device, Apply the diluted emulsion to the overflow and vacuum suction, and then dry it in a steam drying cylinder at 150°C for 2 to 3 minutes.

[0037] The mass percentages of each component in the above-mentioned high-temperature-resistant glass fiber air filter paper are shown in Table 5:

[0038] Table 5: The mass percent of each component of high temperature resistant glass fiber air filter paper in embodiment 3

[0039]

[0040] The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com