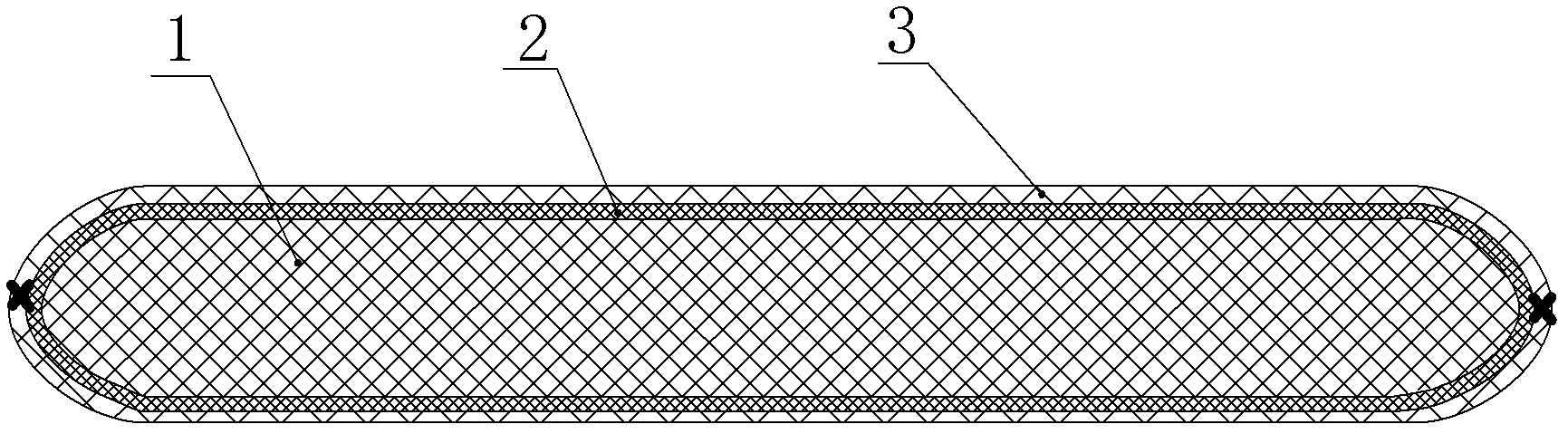

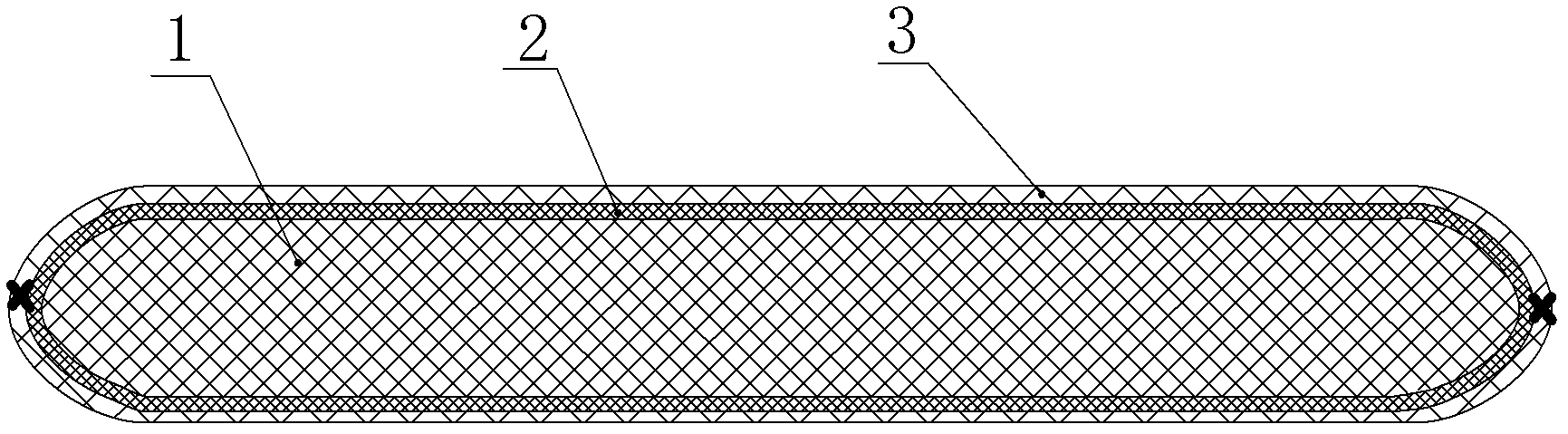

Cotton padding and preparation method thereof

A batt, cotton technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of loss of resilience of cotton fibers, detachment of gauze and cotton batts, loss of heat preservation function, etc. The effect of breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Cotton 1.8kg (high-quality lint above grade 3), natural bamboo fiber 0.3kg (average fineness: 6dtex, average length 95mm), far-infrared hollow polyester staple fiber 0.3kg (6.67dtex*60mm), antibacterial polyester hollow fiber 0.3kg (6.67 dtex*60mm), low melting point fiber 0.3kg (4.45dtex*51mm);

Embodiment 2

[0042] Cotton 1.5kg (high-quality lint above grade 3), bamboo carbon hollow polyester fiber 0.45kg (6.67dtex*60mm), three-dimensional crimped hollow fiber 0.45kg (6.67dtex*64mm), low melting point fiber 0.6kg (4.45dtex*51mm) ;

Embodiment 3

[0044] Cotton 2.1kg (high-quality lint above grade 3), natural bamboo fiber 0.3kg (average fineness: 6dtex average length 95mm), three-dimensional crimped hollow fiber 0.45kg (6.67dtex*64mm), low melting point fiber 0.15kg (4.45dtex* 51mm);

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com