Copper-in-tin electromagnetic screen textile and method for preparing same

A technology of electromagnetic shielding and textiles, applied in the field of electromagnetic shielding textiles and its preparation, can solve the problems of poor conductivity, difficulty in brazing, and inability to maintain textiles, etc., and achieve the effect of good conductivity and easy brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

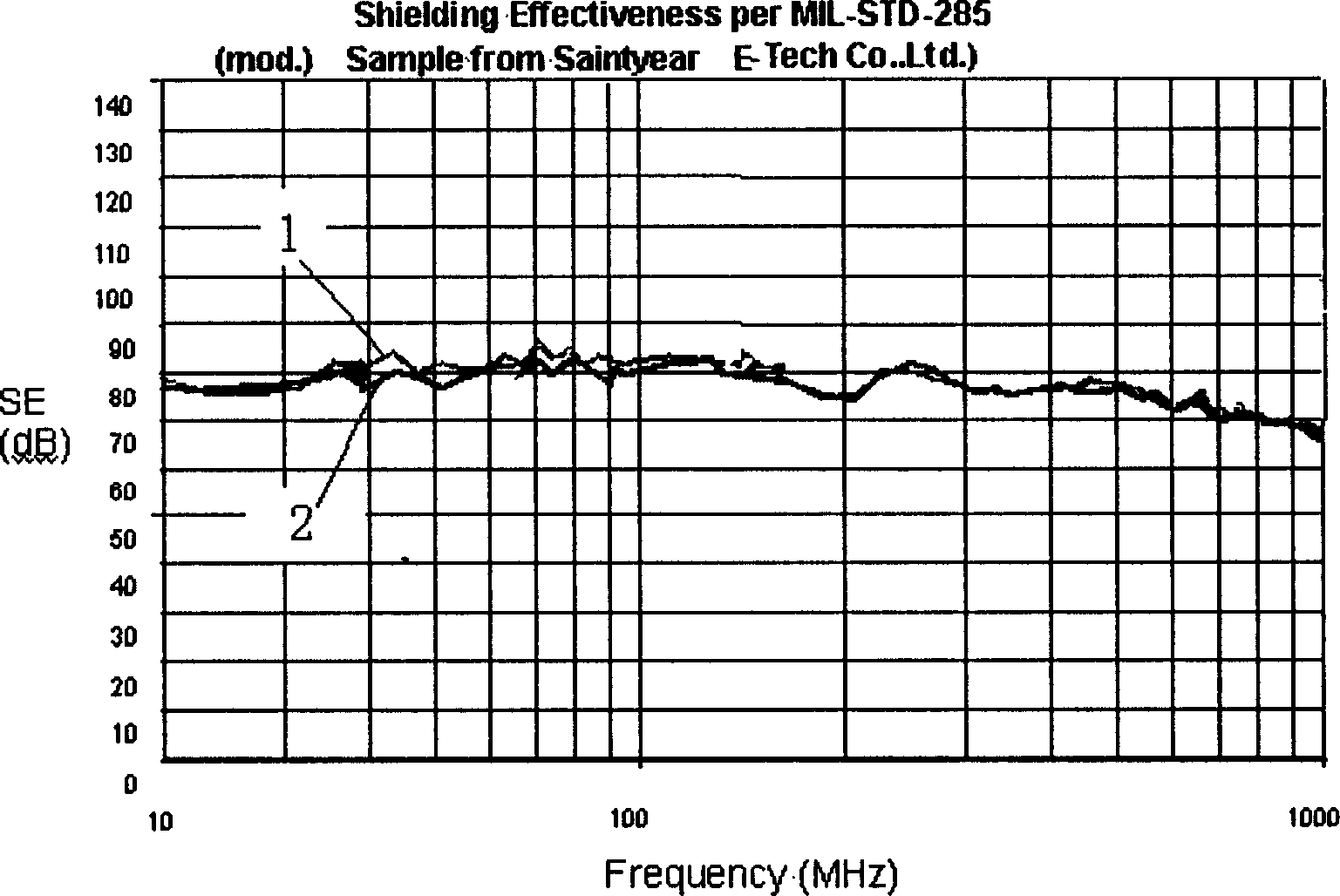

Image

Examples

Embodiment 1

[0057] In this example, nylon 66 textile "RIPSTOP" is used as the base material, and the preparation steps are as follows:

[0058] The first step, pretreatment, desizing and refining with sodium hydroxide solution to clean the surface of the substrate fiber and remove the dirt on the fiber surface;

[0059] In the second step, sensitization and activation, the base fiber is immersed in an aqueous solution of palladium chloride with a weight concentration of 0.53g / l to form an extremely thin metal catalytic layer on the surface of the fiber, and then dried by a heat setting machine MONFORTS 328;

[0060] Working fluid formula: (total 1800L)

[0061] PdCl2 0.53g / l

[0062] HCl(35%) 10ml / l

[0063] SBR Latex 60g / l

[0064] Liquid retention rate 65%

[0065] 180℃, 9min

[0066] The third step is strengthening, soaking with 40% formaldehyde solution to strengthen the surface structure of the fiber;

[0067] The fourth step, electroless copper plating process

[0068] Plating ...

Embodiment 2

[0105] In this embodiment, polyester taffeta is used as the base material, and the preparation steps are as follows:

[0106] Other preparation steps remain unchanged, and the plating solution formula of the fourth step electroless copper plating process is changed as follows accordingly:

[0107] Copper sulfate CuSO4·5H2O 16g / L

[0108] Sodium Potassium Tartrate NaKC4H4O6 4H2O 15g / L

[0109] EDTA Tetrasodium Salt 25g / L

[0110] Alkaline agent such as NaOH 20g / L

[0111] Formaldehyde HCHO (concentration 37-40%) 20g / L

[0112] Tin chloride NiCl2 6H2O 1g / L

[0113] α,α'-bipyridine 20mg / L

[0114] Potassium cyanide 8mg / L

[0115] Penetrant JFC (isobutylphenol polyoxyethylene ether) 2g / L

[0116] pH value 12~13

[0117] The temperature is 47°C.

[0118] The plating solution of the above formula is prepared separately by two groups of A and B, mixed before use, and finally added with a stabilizer to adjust the pH value.

[0119] Group A includes copper sulfate and formald...

Embodiment 3

[0143] In this embodiment, polyester taffeta is used as the base material, and the preparation steps are as follows:

[0144] Other preparation steps remain unchanged, and the plating solution formula of the fourth step electroless copper plating process is changed as follows accordingly:

[0145] Copper sulfate CuSO4·5H2O 16g / L

[0146] Sodium Potassium Tartrate NaKC4H4O6 4H2O 15g / L

[0147] EDTA Tetrasodium Salt 25g / L

[0148] Alkaline agent such as NaOH 20g / L

[0149] Formaldehyde HCHO (concentration 37-40%) 20g / L

[0150] Tin chloride NiCl2 6H2O 1g / L

[0151] α,α'-bipyridine 20mg / L

[0152] Potassium cyanide KCN 8mg / L

[0153] Potassium thiocyanate (KSCN) 12mg / L

[0154] Penetrant JFC 2g / L

[0155] pH value 12~13

[0156] Temperature 47°C

[0157] The plating solution of the above formula is prepared separately by two groups of A and B, mixed before use, and finally added with a stabilizer to adjust the pH value.

[0158] Group A includes copper sulfate and form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com