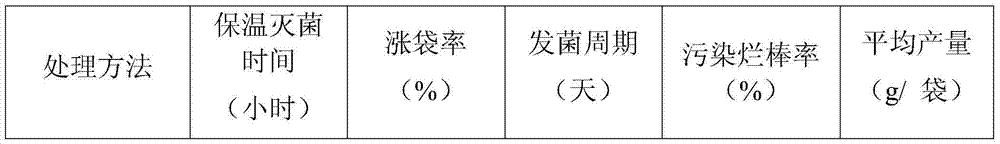

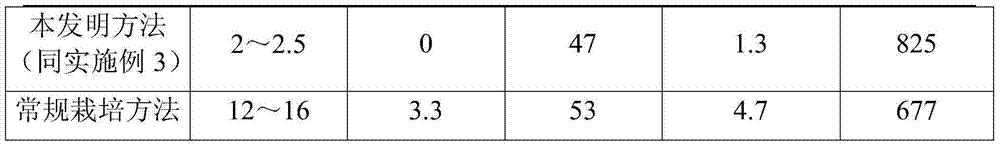

Method for improving preparing efficiency and yield and quality of shiitake sticks

A technology for preparing high-efficiency and high-efficiency shiitake mushroom sticks, which is applied in botany equipment and methods, mushroom cultivation, horticulture, etc., can solve the problems of easy burning of bacteria caused by puncturing, time-consuming and labor-intensive, and long time for bacteria to grow. Shorten the germination cycle, improve the quality and output, and achieve the effect of uniform germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: (a kind of method that improves " Zhexiang No. 6 " shiitake mushroom stick preparation efficiency and yield quality)

[0027] The concrete steps of this method are:

[0028] (1) Preparation of the cultivation inner bag: take the double-layer 15cm×55cm×0.0045cm high-pressure resistant polypropylene film folded in half as the material, and use needles at a longitudinal interval of 4cm from the side 5cm away from the material, The horizontal interval is 5cm, and the double-layer film is pierced downward, and the above method is repeated until the bottom edge, and after forming 6 breathing hole strips with a pore size of 0.03-0.05cm and distributed in strips, it is made into a corner-shaped plastic bag for cultivation. inner bag;

[0029] (2) Preparation of rods:

[0030] 1) Preparation and bagging of compost: Mix sawdust, wheat bran, gypsum, sugar and water as ingredients, and mix them evenly in the proportion of 34:8:0.5:0.5:57 by weight to form compost fo...

Embodiment 2

[0040] Embodiment 2: (a kind of method that improves " L26 " mushroom stick preparation efficiency and yield quality)

[0041] In this example, the preparation of the cultivation inner bag in step (1): The double-layer 25cm×55cm×0.0045cm high-pressure resistant polypropylene tubular membrane folded in half is used as the material, and the pore diameter formed is 0.03-0.05cm, and the breathing hole strip There are 10 pieces in total, and the material is used to make a large angled plastic bag as a cultivation inner bag; step (2) preparation of material rod: 1) preparation and bagging of culture material: use miscellaneous wood chips, wheat bran, gypsum, sugar and water as The ingredients are mixed evenly in the ratio of 35:8.5:0.5:0.5:55.5 by weight to become compost for cultivating shiitake mushrooms; they are packed into large bags with breathing holes, each bag weighing 2.7-2.8 kilograms; 2) Sterilization of feed rods: Put the big bag material rod on the polypropylene plasti...

Embodiment 3

[0042] Embodiment 3: (a kind of method that improves " L808 " mushroom stick preparation efficiency and yield quality)

[0043] In this example, step (1) preparation of the cultivation inner bag: the double-layer 15cm×55cm×0.0045cm high-pressure resistant polypropylene tubular membrane folded in half is used as the material, and the pore diameter formed is 0.03-0.05cm, and the breathing hole strip A total of 6 pieces, using the material to make a corner-shaped plastic bag as the cultivation inner bag; step (2) preparation of material stick: 1) preparation and bagging of culture material: use miscellaneous wood chips, wheat bran, gypsum, sugar and water as The ingredients are mixed evenly in the proportion of 36:9:0.5:0.5:54 by weight to form compost for cultivating shiitake mushrooms; packed into small bags with breathing holes, each bag weighing 1.6-1.7 kg; 2) Sterilization of the rod: Cover the small bag material stick with a polypropylene plastic outer bag of 17cm × 60cm × ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com