Gel polymer electrolyte for lithium ion battery, and preparation method thereof

A gel polymer and electrolyte technology, applied in solid electrolytes, non-aqueous electrolytes, secondary batteries, etc., can solve the problems that the research results have not yet reached, and achieve high electrochemical stability, good thermal shrinkage resistance, and high electrical conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Correspondingly, the preparation method of the gel polymer electrolyte includes the following steps:

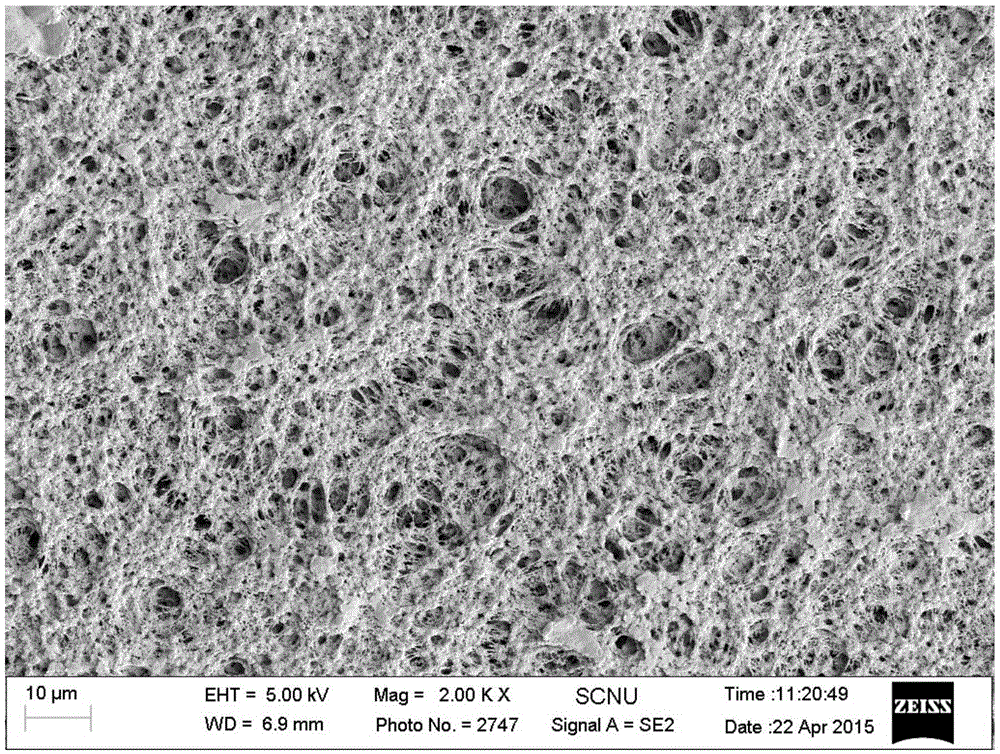

[0046] The polyvinylidene fluoride and cellulose acetate butyrate are co-dissolved in the solvent to form liquid 1, and then the carbomer resin is added to liquid 1 and fully stirred to form liquid 2. Finally, the polyolefin microporous membrane is immersed in liquid 2. The polymer film formed after drying is immersed in the electrolyte and taken out.

[0047] Preferably, the solvent is at least one of DMF, NMP and DMC.

[0048] Preferably, the mass ratio of polyvinylidene fluoride and cellulose acetate butyrate is (1-4): 1, and the sum of the mass of polyvinylidene fluoride and cellulose acetate butyrate accounts for 3% to 10% of the mass of liquid 1.

[0049] Preferably, the mass of the carbomer resin accounts for 0.01% to 0.2% of the total mass of the liquid 2;

[0050] Preferably, the polyolefin microporous film is immersed in the liquid 2 for 0.5h to 1h, the dry...

Embodiment 1

[0057] (1) Weigh 63g of DMF and 27g of DMC in a beaker, stir magnetically at 25°C for 30min, and mix well.

[0058] (2) Weigh 6.6 g of PVdF and 3.3 g of CAB into the mixed solvent of step (1), and stir magnetically at 25° C. for 6 h.

[0059] (3) Weigh 0.2 g of carbomer resin into the liquid obtained in step (2), and stir magnetically at 25° C. for 1 h.

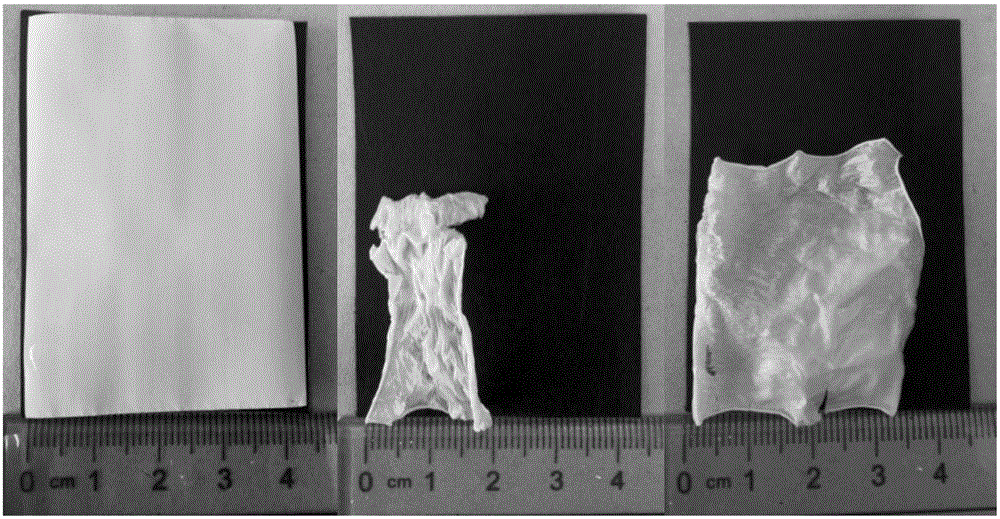

[0060] (4) The polypropylene microporous membrane is immersed in the liquid obtained in step (3), taken out after 0.5 h, air-dried at room temperature, and then transferred to a vacuum drying oven for drying at 60° C. for 24 h to obtain a polymer membrane.

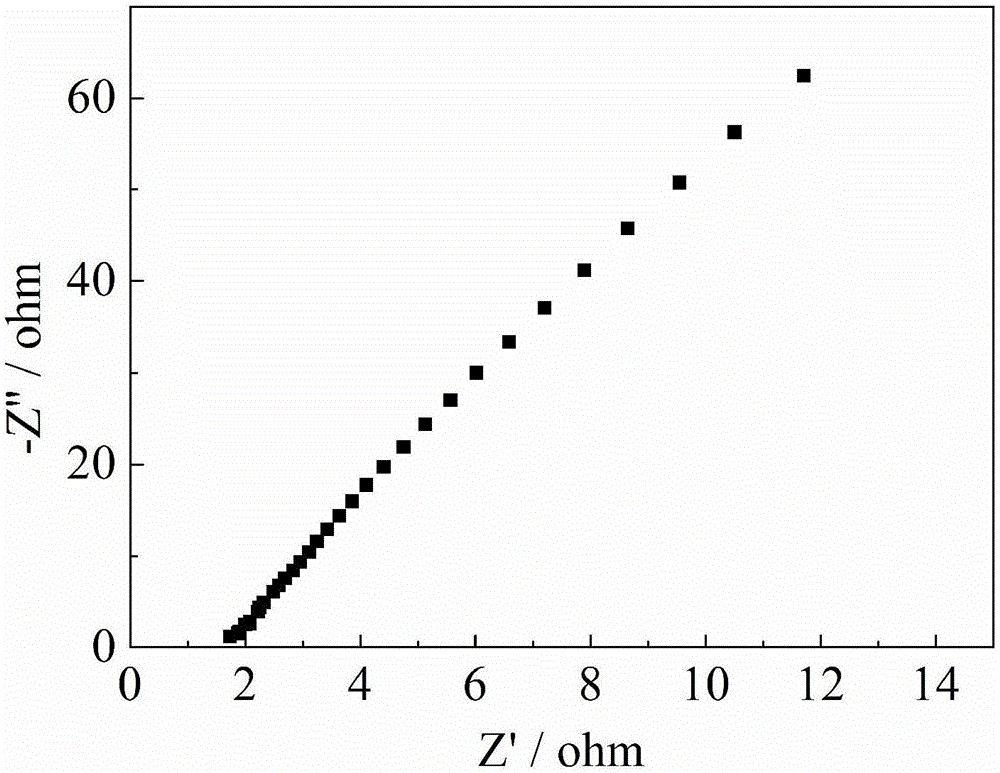

[0061](5) The polymer film obtained in step (4) is sliced, and the obtained round polymer film is immersed in an electrolyte solution for 1 hour under an argon atmosphere to prepare a gel polymer electrolyte. The electrolyte solvent adopts EC:DMC:DEC=1:1:1, and the lithium salt adopts LiPF 6 , the concentration is 1mol / L;

[0062] (6) The gel polymer electrolyte obtain...

Embodiment 2

[0064] (1) Weigh 90 g of NMP into a beaker.

[0065] (2) Weigh 6.6 g of PVdF and 3.3 g of CAB into the NMP described in step (1), and stir magnetically at 25° C. for 24 h.

[0066] (3) Weigh 0.01 g of carbomer resin into the liquid obtained in step (2), and stir magnetically at 25° C. for 1 h.

[0067] (4) The polypropylene microporous membrane is immersed in the liquid obtained in step (3), taken out after 0.5 h, air-dried at room temperature, and then transferred to a vacuum drying oven for drying at 60° C. for 24 h to obtain a polymer membrane.

[0068] (5) The polymer film obtained in step (4) is sliced with a microtome, and the obtained round polymer film is immersed in an electrolyte solution for 1 hour under an argon atmosphere to prepare a gel polymer electrolyte. The electrolyte solvent adopts EC:DMC:DEC=1:1:1, and the lithium salt adopts LiPF 6 , the concentration is 1mol / L.

[0069] (6) The gel polymer electrolyte obtained in step (5) is assembled into a button...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com