Method needing no vacuum process to prepare organic polymer solar cell

A technology of solar cells and polymers, which is applied in the field, can solve the problems that are not conducive to large-area preparation, complicated process, high energy consumption, etc., and achieve the effects of improving device manufacturing efficiency, simplifying device manufacturing process, and reducing device manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

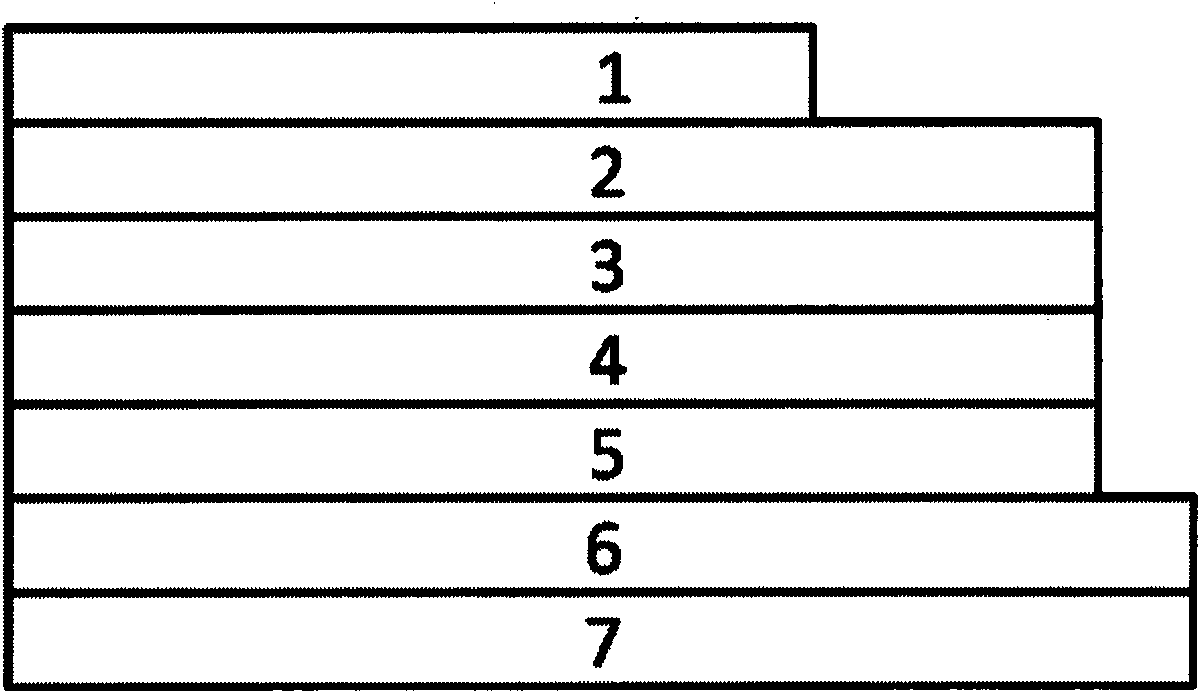

Method used

Image

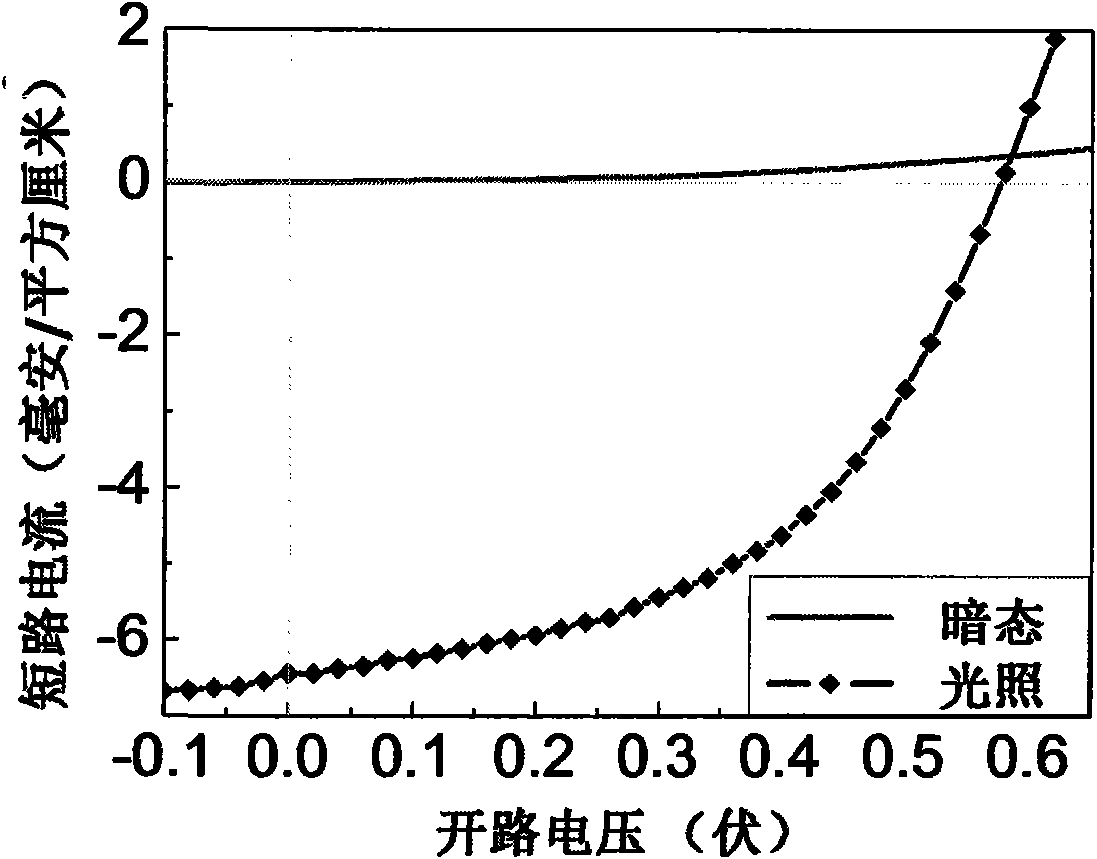

Examples

Embodiment 1

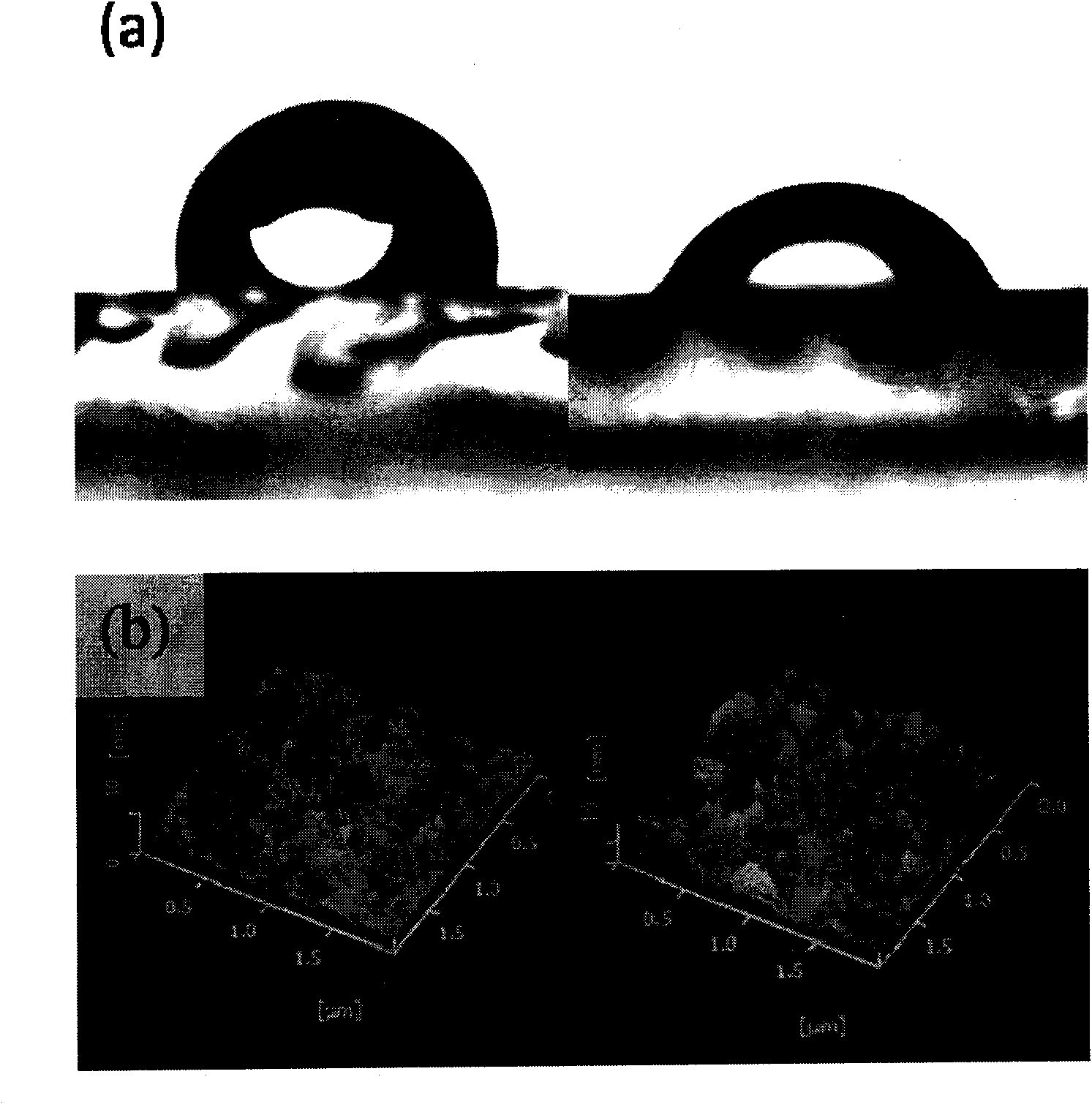

[0042] Solution configuration: the conjugated polymer donor material P3HT and the acceptor material PC 60 BM was dissolved in ODCB solvent at a mass ratio of 1:0.8 to prepare a 50 mg / ml solution and stirred at room temperature for 5 hours to fully dissolve it. The amphiphilic self-assembled molecule PAH-D:PSS was configured as a 1 mg / ml aqueous solution, and the pH value of the solution was adjusted to 10 by adding NaOH. Add dimethyl sulfoxide (DMSO) into PEDOT:PSS (PH500) to configure a mixed solution with a volume fraction of DMSO of 5%.

[0043] Preparation of ZnO-modified ITO cathode: (1) Treatment of ITO substrate: The ITO glass was ultrasonically cleaned in acetone, isopropanol and deionized water for 15 minutes in sequence. Then dry at 120 degrees Celsius for 10 minutes.

[0044] (2) Preparation of ZnO nanoparticles: Add 13.4 millimoles of zinc acetate to 125 milliliters of methanol, stir and reflux at 60 degrees Celsius for 30 minutes; dissolve 23 millimoles of KOH i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com