Preparation method and application of uniform-size graphene quantum dots

A graphene quantum dot, uniform size technology, applied in the field of nanomaterials, can solve problems such as being unsuitable for mass production and application, uncontrollable size, cumbersome process steps, etc., achieve mild conditions, accelerate electron transfer rate, and increase active area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

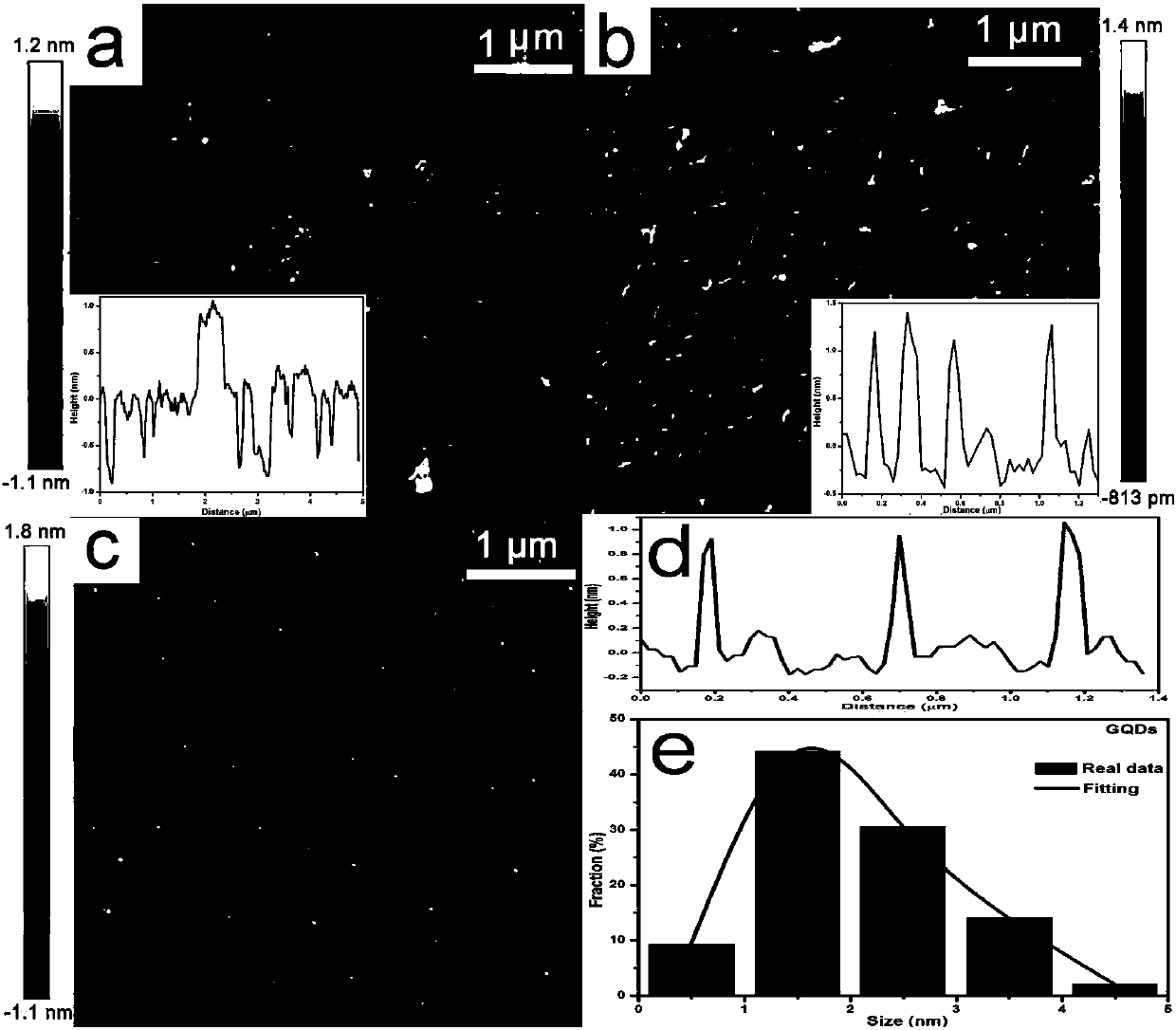

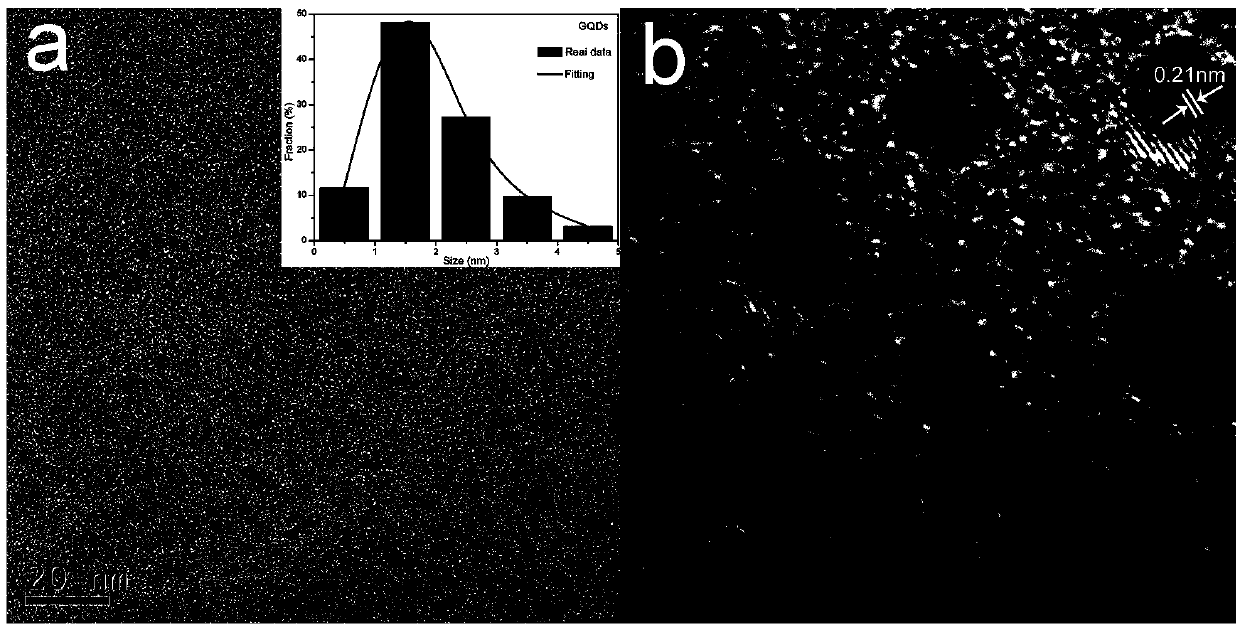

[0039] (1) Preparation of graphene oxide: Add 26mL of concentrated sulfuric acid to a beaker in an ice-water bath at 0°C, then add graphite powder 1g, sodium nitrate 0.5g, add potassium permanganate 3g in small quantities, and stir for 2 hours from ice Remove from water bath. Add 46mL of water into the beaker, control the temperature of the system at 35°C, and stir the reaction for 30min. Then, keep stirring at 95°C for 15 minutes, then add 140mL of warm water. Add 3.3% H dropwise 2 o 2 solution until there are no more bubbles in the system. Centrifuge, and then wash with 5% hydrochloric acid solution, absolute ethanol, and deionized water. The precipitate obtained by centrifugation was put into a vacuum freeze dryer, and dried at -45° C. for 24 hours to obtain graphite oxide powder. The obtained graphene oxide is as attached Figure 1 (a) shows a monolithic layer with a smooth surface and a thickness of about 1 nm due to the presence of oxygen-containing groups.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com