Three-layered structured oxide fuel cell supported by stainless steel and preparation method thereof

A fuel cell and stainless steel technology, which is applied in fuel cells, fuel cell parts, solid electrolyte fuel cells, etc., can solve the problems of complex overall structure and preparation process of the battery, reduce the charge conduction efficiency of the battery, and achieve excellent thermal cycle resistance and anti-oxidation-reduction cycle and other resistance, safe long-term output, and the effect of increasing the active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

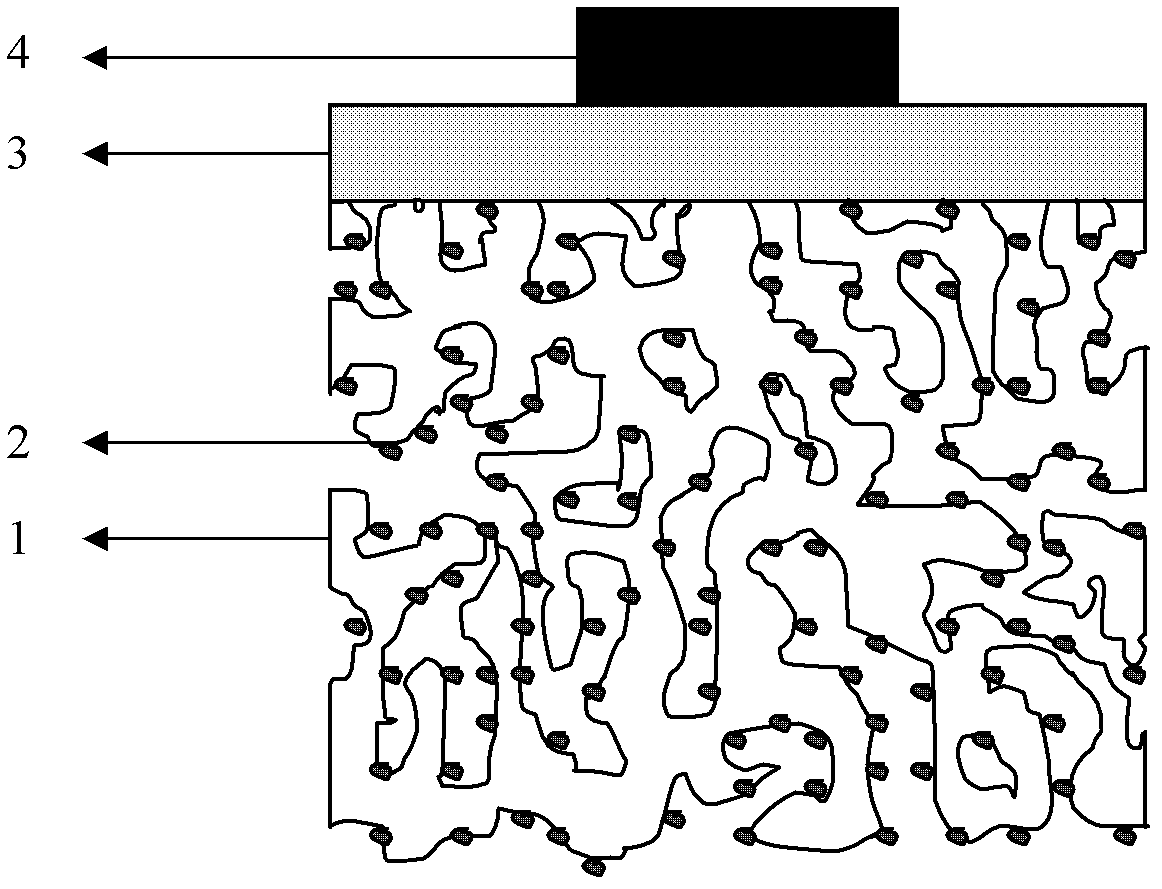

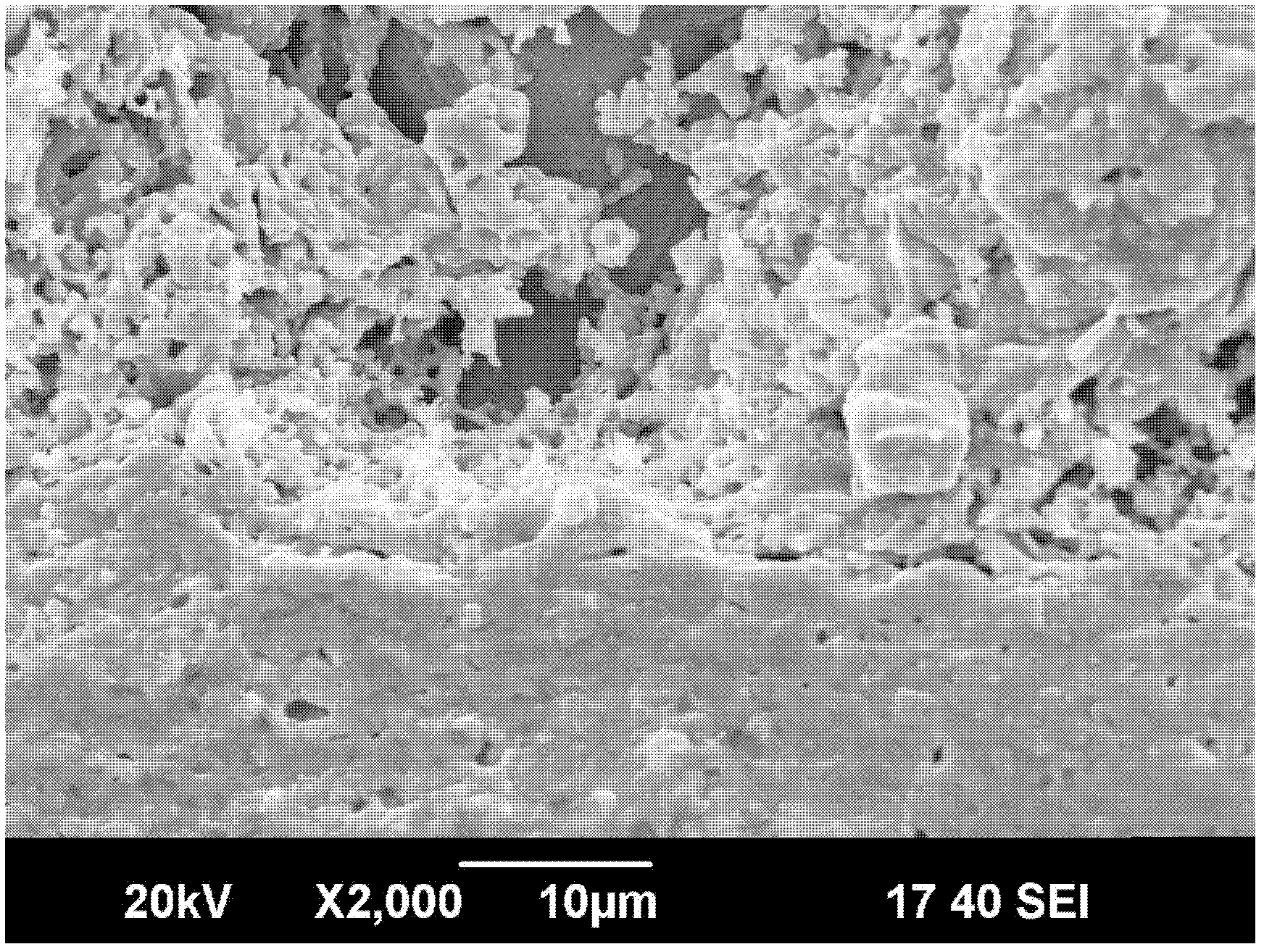

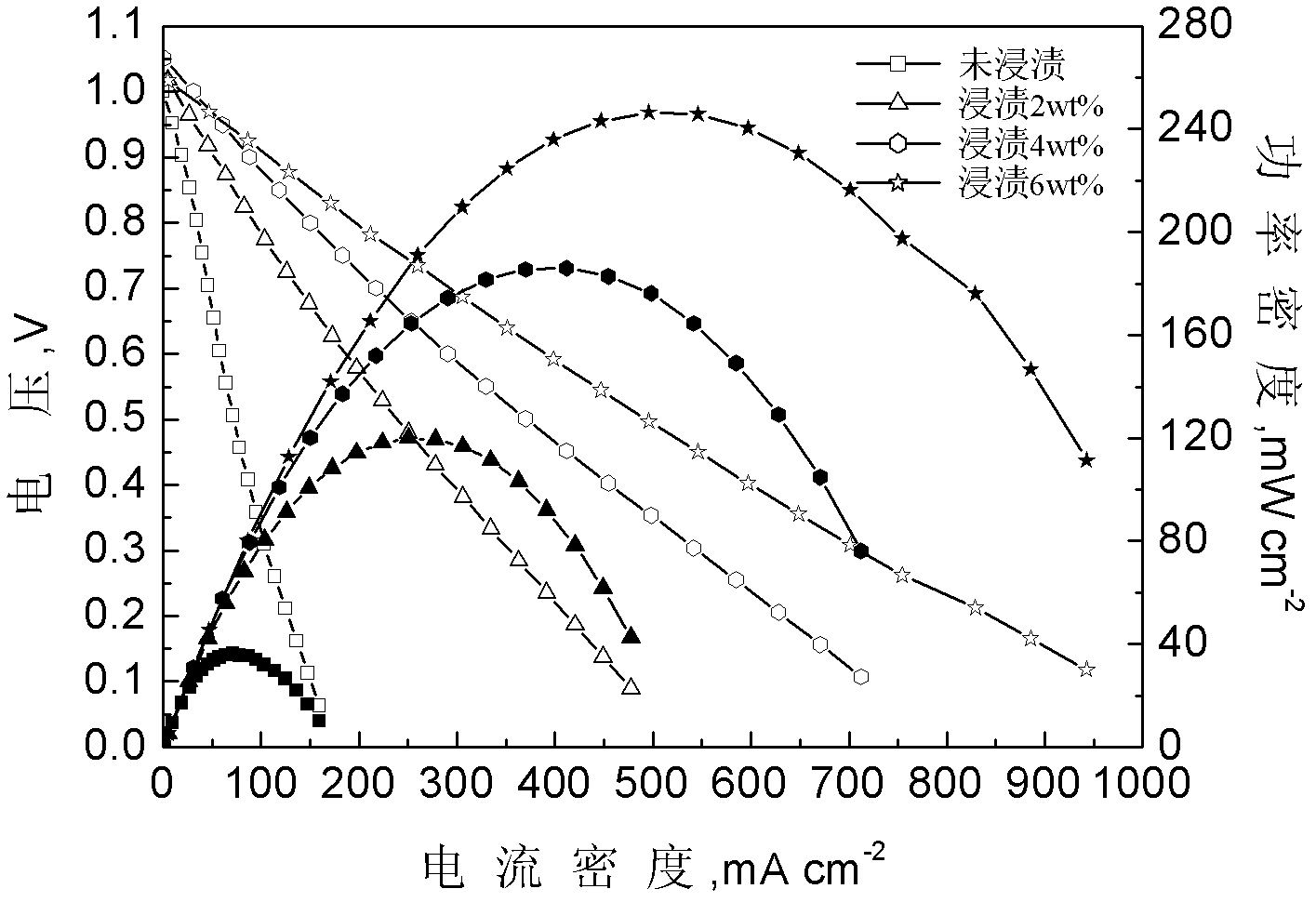

[0038] Example 1: SS430-YSZ(Ni-SDC) / YSZ / LSM-YSB three-layer structure stainless steel support SOFC

[0039] (1) Electrolyte YSZ (8mol% Y 2 o 3 -ZrO 2 ) powder and LSM in the cathode ((La 0.85 Sr 0.15 ) 0.9 SrMnO 3-δ ) and YSB((Y 0.25 Bi 0.75 ) 2 o 3 ) powder: Taking the synthesis of YSZ as an example, the pre-calibrated Y(NO 3 ) 3 , Zr(NO 3 ) 4 Mixed stoichiometrically, keeping Y 3+ and Zr 4+ The molar ratio of the substance is 0.16:0.92, forming the nitrate precursor Y 0.16 Zr 0.92 (NO 3 ) x solution, then add glycine as a complexing agent, the amount of required glycine is half of the total amount of nitrate ions, and stir for 1 hour to fully complex after glycine is dissolved. Then, take about 0.02mol of Y each time 0.16 Zr 0.92 (NO 3 ) x The precursor solution was placed in a 1000mL beaker, heated on a 500W electric hot plate, and the excess water was evaporated. After the solution becomes viscous, continue to heat, and the jelly starts to burn, and...

Embodiment 2

[0049] Embodiment 2: SS430-YSZ (Ni-CeO 2 ) / YSZ / LSM-YSB three-layer stainless steel support SOFC

[0050] (1) Electrolyte YSZ (8mol% Y 2 o 3 -ZrO 2 ) powder and LSM in the cathode ((La 0.85 Sr 0.15 ) 0.9 MnO 3-δ ) and YSB((Y 0.25 Bi 0.75 ) 2 o 3 ) powder: Taking the synthesis of LSM as an example, the pre-calibrated La(NO 3 ) 3 , Sr(NO 3 ) 2 and Mn(NO 3 ) 2 Mixed stoichiometrically, keeping La 3+ 、Sr 2+ and Mn 2+ The molar ratio of the substances is 0.765:0.135:1, forming the nitrate precursor La 0.765 Sr 0.135 Mn(NO 3 )x solution, then add glycine as a complexing agent, the amount of required glycine is half of the total amount of nitrate ions, and stir for 1 hour to fully complex after glycine is dissolved. Then, take about 0.02mol of La each time 0.765 Sr 0.135 Mn(NO 3 )x precursor solution was placed in a 1000mL beaker, heated on a 500W electric hot plate, and excess water was evaporated. After the solution becomes viscous, continue to heat, and th...

Embodiment 3

[0056] Example 3: SS430-YSZ(Ni-SDC) / YSZ / LSM-SDC three-layer structure stainless steel support SOFC

[0057](1) Electrolyte YSZ (8mol% Y 2 o 3 -ZrO 2 ) powder and LSM in the cathode ((La 0.85 Sr 0.15 ) 0.9 SrMnO 3-δ ) and SDC (Sm 0.2 Ce 0.8 o 1.9 ) powder: Taking the synthesis of SDC as an example, the pre-calibrated Sm(NO 3 ) 3 , Ce(NH 4 ) 2 (NO 3 ) 6 (Note: Practice found that Ce(NH 4 ) 2 (NO 3 ) 6 The performance of SDC powder made as raw material is higher than that of Ce(NO 3 ) 3 The performance is better at the time) mix according to the stoichiometric ratio, keeping Sm 3+ and Ce 4+ The molar ratio of the substances is 0.2:0.8, forming the nitrate precursor Sm 0.2 Ce 0.8 (NH 4 ) 1.6 (NO 3 ) x solution, and then add glycine as a complexing agent, the amount of glycine required is half of the total amount of nitrate ions (note: here need to deduct NH 4 + Can consume NO 3 - , each NH 4 + consume a NO 3 - ), and stir for 1 hour to fully comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com