Positive electrode active material and nonaqueous electrolyte secondary cell

A positive electrode active material, non-aqueous electrolyte technology, applied in secondary batteries, secondary battery repair/maintenance, active material electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The embodiments of the present invention will now be described based on specific experimental results. However, it can be understood that the present invention is not limited to the embodiments.

[0061] [Experiment 1-1]

[0062] First check Li m Co x Al y Mg z O 2 The numerical range of y and z in.

[0063] Sample 1

[0064] First, the positive electrode active material was produced as follows. Commercially available lithium carbonate, cobalt oxide, aluminum hydroxide and magnesium carbonate were mixed together in a molar ratio of Li, Co, Al and Mg of 1.02:0.98:0.01:0.01. The resulting mixture was sintered in a stream of dry air using a crucible made of alumina. When the obtained powder was quantitatively analyzed by atomic absorption analysis method, it was confirmed that LiCo 0.98 Al 0.01 Mg 0.01 O 2 Composition. When the powder was subjected to X-ray diffraction measurement, it was confirmed that the pattern of the powder was similar to LiCoO in 36-1004 of ICDD (Interna...

Embodiment 2

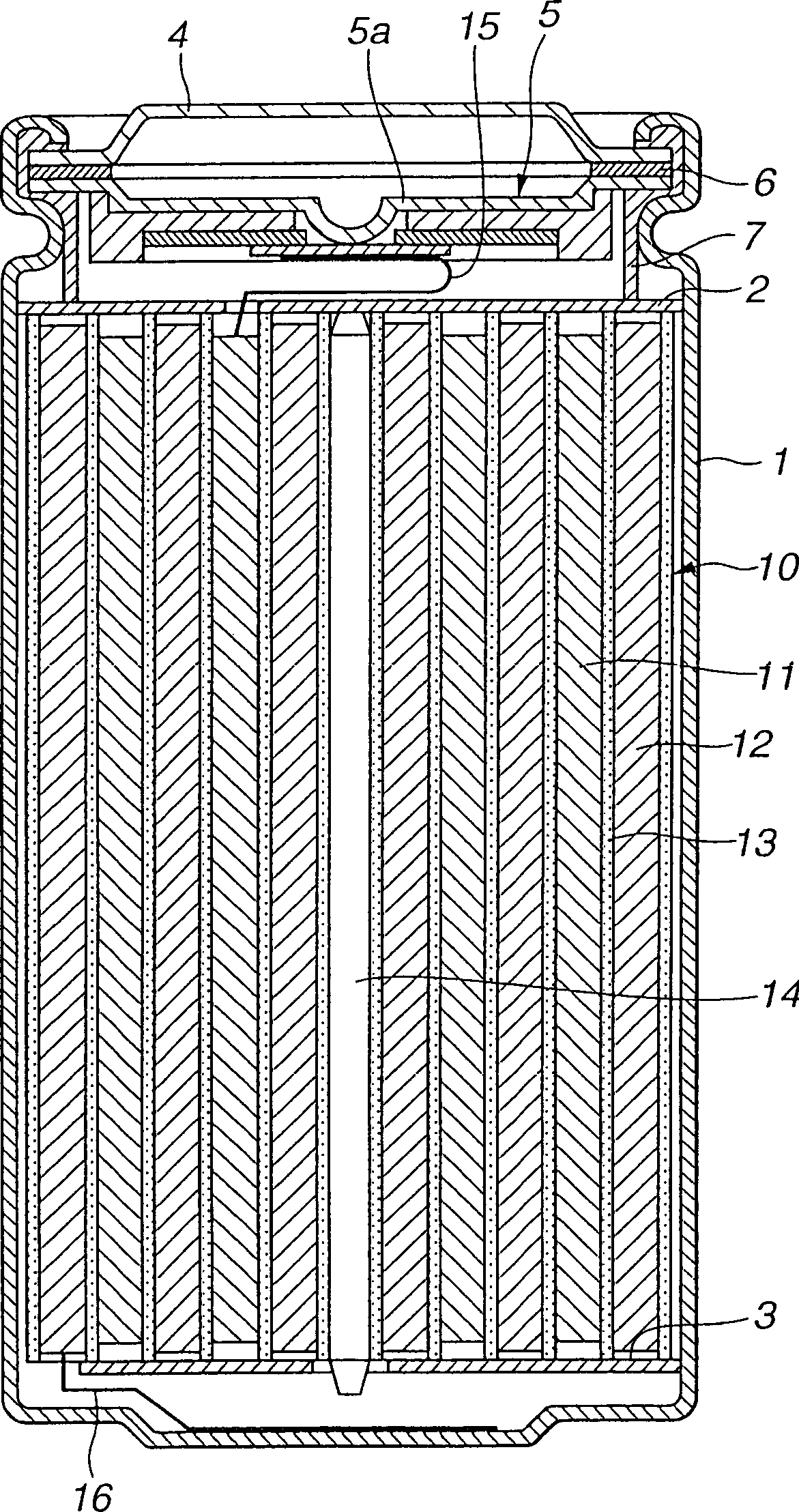

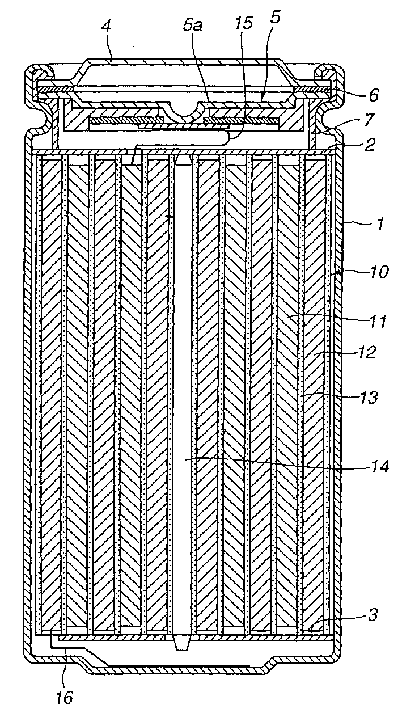

[0113] The cross-sectional structure of the non-aqueous secondary battery as the second embodiment of the present invention is given below. Because the non-aqueous secondary battery has figure 1 The non-aqueous electrolyte secondary battery shown has the same configuration, and the elements having the same operations and functions are denoted by the same reference numerals, so detailed explanations thereof are omitted.

[0114] By caulking the gasket 7, the battery cover 4, the safety valve device 5 and the positive temperature coefficient element (PTC element) 6 located in the battery cover 4 are connected to the open end of the same battery container 1. The inside of the battery container 1 is sealed. The battery cover 4 is made of, for example, the same material as the battery container 1. The safety valve device 5 is electrically connected to the battery cover 4 through the positive temperature coefficient element 6, so that when the internal pressure of the battery reaches a ...

Embodiment 3

[0139] The non-aqueous electrolyte secondary battery given as the third embodiment of the present invention has figure 1 The non-aqueous electrolyte secondary battery shown has the same structure, except that the anode includes a specific negative electrode active material. Therefore, elements having the same operations and functions as those of the non-aqueous electrolyte secondary battery of the first embodiment are denoted by the same reference numerals, and detailed explanations thereof are omitted.

[0140] In the non-aqueous electrolyte secondary battery given as the third embodiment, the cathode 11 is composed of, for example, a cathode composite mixture layer and a cathode current collector layer. The cathode composite mixture layer is located on both surfaces or one surface of the cathode current collector layer in the structure. The cathode current collector layer is composed of metal foil, for example, aluminum foil, nickel foil or stainless steel foil. In the cathode c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com