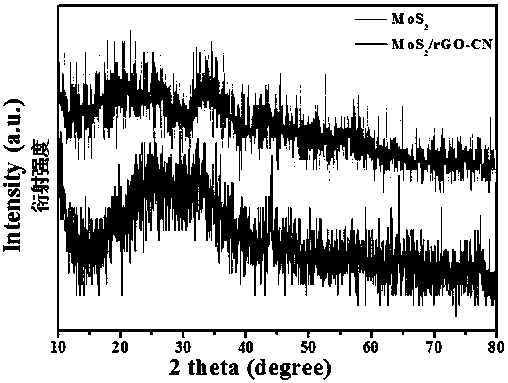

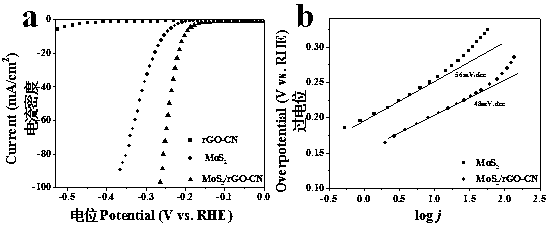

Preparation method and application of MoS2/rGO-CN composite material

A composite material, rgo-cn technology, applied in the field of electrocatalytic hydrogen evolution, can solve the problems of poor conductivity and easy accumulation of molybdenum disulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

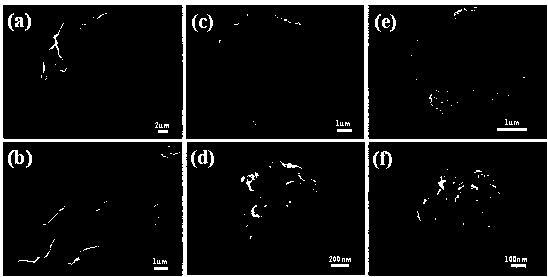

Embodiment 1

[0029] Weigh 45 mg of graphite oxide and place it in a beaker, add 15 mL of deionized water, ultrasonically disperse and then add 27 mg of melamine to ultrasonically dissolve again to form a colloidal solution. The above colloidal solution was transferred to a 25 mL polytetrafluoroethylene-lined reactor, and then the reactor was placed in an oven at 120 °C for 6 h, cooled to room temperature, and finally freeze-dried to obtain a black substance. Then transfer the obtained black substance into a porcelain boat, and then transfer it to a temperature-programmed tube furnace. Under the protection of argon, the temperature-programmed tube furnace is heated to 600 °C at a heating rate of 2.3 °C / min and then kept for 2 hours. After being naturally cooled to room temperature, it was taken out to obtain reduced graphene oxide-nitrogen carbide (rGO-CN).

[0030] Weigh 1 mg ammonium tetrathiomolybdate ((NH 4 ) 2 MoS 4 ) and 2 mg rGO-CN were placed in a beaker, then 15 mL DMF was added...

Embodiment 2

[0032] Weigh 45 mg of graphite oxide and place it in a beaker, add 15 mL of deionized water, ultrasonically disperse and then add 27 mg of melamine to ultrasonically dissolve again to form a colloidal solution. The above colloidal solution was transferred to a 25 mL polytetrafluoroethylene-lined reactor, and then the reactor was placed in an oven at 120 °C for 6 h, cooled to room temperature, and finally freeze-dried to obtain a black substance. Then transfer the obtained black substance into a porcelain boat, and then transfer it to a temperature-programmed tube furnace. Under the protection of argon, the temperature-programmed tube furnace is heated to 600 °C at a heating rate of 2.3 °C / min and then kept for 2 hours. After being naturally cooled to room temperature, it was taken out to obtain reduced graphene oxide-nitrogen carbide (rGO-CN).

[0033] Weigh 3 mg ammonium tetrathiomolybdate ((NH 4 ) 2 MoS 4 ) and 2 mg rGO-CN were placed in a beaker, then 15 mL DMF was added...

Embodiment 3

[0035] Weigh 45 mg of graphite oxide and place it in a beaker, add 15 mL of deionized water, ultrasonically disperse and then add 27 mg of melamine to ultrasonically dissolve again to form a colloidal solution. The above colloidal solution was transferred to a 25 mL polytetrafluoroethylene-lined reactor, and then the reactor was placed in an oven at 120 °C for 6 h, cooled to room temperature, and finally freeze-dried to obtain a black substance. Then transfer the obtained black substance into a porcelain boat, and then transfer it to a temperature-programmed tube furnace. Under the protection of argon, the temperature-programmed tube furnace is heated to 600 °C at a heating rate of 2.3 °C / min and then kept for 2 hours. After being naturally cooled to room temperature, it was taken out to obtain reduced graphene oxide-nitrogen carbide (rGO-CN).

[0036] Weigh 7 mg ammonium tetrathiomolybdate ((NH 4 ) 2 MoS 4 ) and 2 mg rGO-CN were placed in a beaker, then 15 mL DMF was added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com