Electrospinning and electrostatic spraying method for membrane electrode CCM

An electrostatic spraying and electrospinning technology is applied in the fields of electrospinning and electrostatic spraying preparation. The effect of increasing the three-phase reaction interface and improving the utilization rate of the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 4g 5wt% Nafion solution, 0.05g polyacrylic acid, 0.95g isopropanol and water mixed solution, wherein, the volume ratio of isopropanol and water is 3:1, after mixing, stir magnetically for 8h to obtain a concentration of 5wt%, fully Mixed electrospinning solution. Install aluminum foil on the electrospinning collection drum and ground it. Use a 5mL syringe to take 3mL of the electrospinning solution, install the syringe on a micro-injection pump, and connect the needle of the syringe to the positive electrode of the high voltage source. Adjust the advancing speed of the syringe pump to 0.1mL / h, and turn on the high-voltage power supply and the roller when droplets appear on the needle. The working voltage was adjusted to 12KV, the drum speed was 100rpm, and the electrospinning time was 30min to obtain polymer nanofibers. The measured average diameter of the polymer nanofiber is 250nm, the thickness is 6μm, and the porosity is greater than 70%.

[0033] Cut polym...

Embodiment 2

[0039]Weigh 4g of 5wt% Nafion solution, 0.01g of polyacrylic acid, 2.2g of isopropanol and water mixed solution, wherein, the volume ratio of isopropanol to water is 3:1, after mixing, stir magnetically for 8h to obtain a concentration of 3.4wt%. Thoroughly mix the electrospinning solution. Install aluminum foil on the electrospinning collection drum and ground it. Use a 5mL syringe to take 3mL of the electrospinning solution, install the syringe on a micro-injection pump, and connect the needle of the syringe to the positive electrode of the high voltage source. Adjust the advancing speed of the syringe pump to 0.5mL / h, and turn on the high-voltage power supply and the roller when droplets appear on the needle. The working voltage was adjusted to 12KV, the drum speed was 50rpm, and the electrospinning time was 20min to obtain polymer nanofibers. The measured average diameter of the polymer nanofiber is 160nm, the thickness is 4μm, and the porosity is greater than 70%.

[0...

Embodiment 3

[0044] According to example 2 steps

[0045] Take 10mg of Pt / C catalyst (40wt%Pt), 0.5mg of Nafion, 2.5g of isopropanol and water mixed solution, wherein, the volume ratio of isopropanol to water is 3:1, mix and ultrasonically disperse for 3min to obtain a concentration of 5.7wt %, mix a homogeneous solution. Then replace the electrospinning collection drum with an aluminum plate of an appropriate size, and place the above-mentioned composite film on the aluminum plate. Use a 5ml syringe to take 2mL of the catalyst solution, adjust the distance between the needle aluminum plate to 5cm, the working voltage to 4.5KV, and spray for 20min. Obtain this surface as a membrane electrode anode with a platinum loading of 0.06 mg / cm 2 .Spray on the other side of the membrane for 30 minutes in the same way, as the cathode of the membrane electrode, with a platinum loading of 0.09mg / cm 2 .CCM preparation ends.

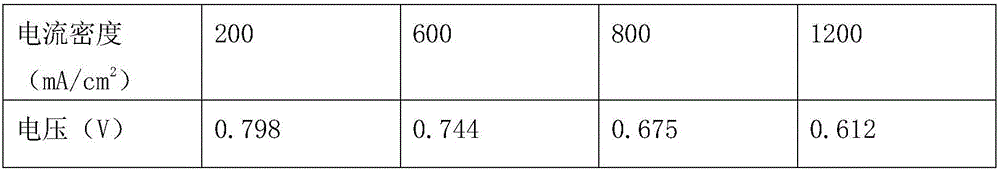

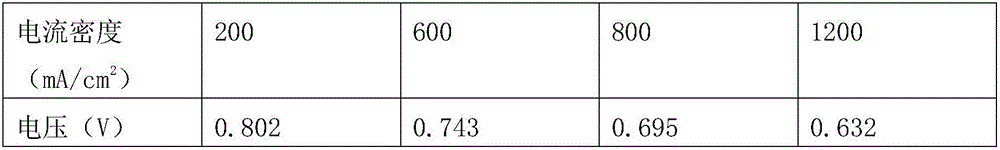

[0046] The CCM and SGL carbon paper were hot-pressed to form a film electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com