Method for modifying positive electrode of lithium ion battery by adding metal oxide/carbon composite material

A lithium-ion battery, carbon composite material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of expensive equipment, high deposition modification cost, unfavorable cycle performance, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

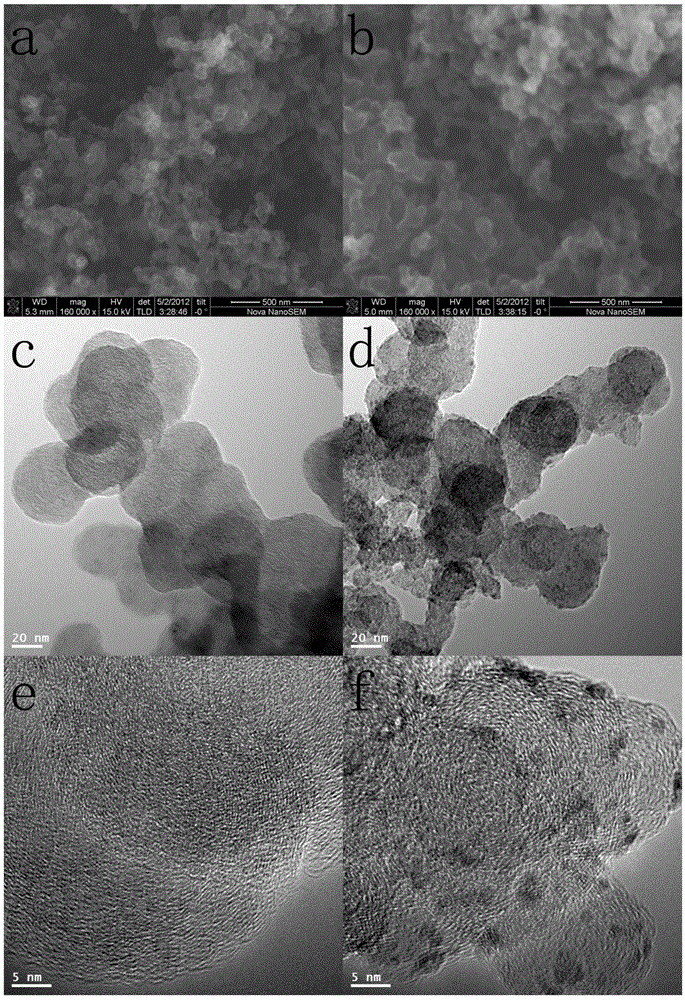

[0035] (1) Weigh 1.496g of conductive carbon black as a carrier of conductive carbon material, mix it with surfactant sodium lignosulfonate in deionized water at a mass ratio of 1:5, ultrasonicate for 1 hour, then filter and wash, after washing, remove the precipitate Add it to 250mL of ruthenium trichloride solution with a concentration of 0.005M, sonicate for 1h, then heat to boiling and stir for 6h, so that the loading precursor is loaded on the surface of the carrier and completely hydrolyzed, then filtered and washed, and dried at 50°C for 5h After drying, a ruthenium oxide / carbon black electrode additive with a ruthenium oxide loading of 10wt% can be obtained through heat treatment at 250° C. for 10 hours;

[0036] (2) Weigh according to the mass ratio of the amount of positive electrode active material, the amount of electrode additives, the amount of N-methylpyrrolidone (NMP) added, and the amount of polyvinylidene fluoride (PVDF) added: 75:5:10:10 A certain amount of ...

Embodiment 2

[0038] (1) Weigh 0.814g of the conductive carbon material carrier graphene, mix it with the surfactant triethanolamine lauryl sulfate in deionized water at a mass ratio of 1:5, ultrasonicate for 1h, then filter and wash, after washing, add the precipitate to Add 250mL of zinc dichloride solution with a concentration of 0.010M, ultrasonically treat for 1h, then add 300mL of aqueous sodium hydroxide solution with a concentration of 0.010M and stir for 6 hours, then filter and wash, dry at 50°C for 5h, and then A zinc oxide / graphene additive with a zinc oxide load of 20wt% can be prepared by heat treatment at 250°C for 10 hours;

[0039] (2) Take a certain amount of positive electrode active material Li (Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 , electrode additives, NMP, PVDF, Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 Mix with electrode additives and grind for 1 hour, then add NMP, stir for 1 hour, then add binder PVDF, stir for 8 hours to obtain a uniform slurry, use a scraper to evenly coat the sl...

Embodiment 3

[0041] (1) Weigh 0.599g of conductive carbon material carrier carbon nanotubes, mix them with surfactant sodium dodecylsulfonate in deionized water according to a mass ratio of 1:5, ultrasonically treat for 1h, then filter and wash, after washing, Add the precipitate to 250 mL of titanium isopropoxide solution with a concentration of 0.02M, sonicate for 1 h, then add 25 mL of deionized water and stir for 6 h, so that the titanium isopropoxide is completely hydrolyzed and loaded onto the surface of the carrier, then filtered and washed, and then washed at 50 After drying for 5 hours at ℃, heat treatment at 250 ℃ for 10 hours can produce a titanium dioxide / carbon nanotube electrode additive with a loading capacity of titanium dioxide of 40 wt%.

[0042] (2) Weigh a certain amount of positive electrode active material LiNi according to the mass ratio of the amount of positive electrode active material, the amount of electrode additives, the amount of NMP added, and the amount of P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com