Poly-pyrrole minisize super capacitor based on MEMS technique and method for manufacturing the same

A supercapacitor and polypyrrole technology, which is applied in the direction of capacitors, electrolytic capacitors, and capacitor components, can solve the problems of reduced reliability of micro-energy devices, increased processing difficulty, and complicated preparation processes, so as to improve high-current discharge performance and increase The effect of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

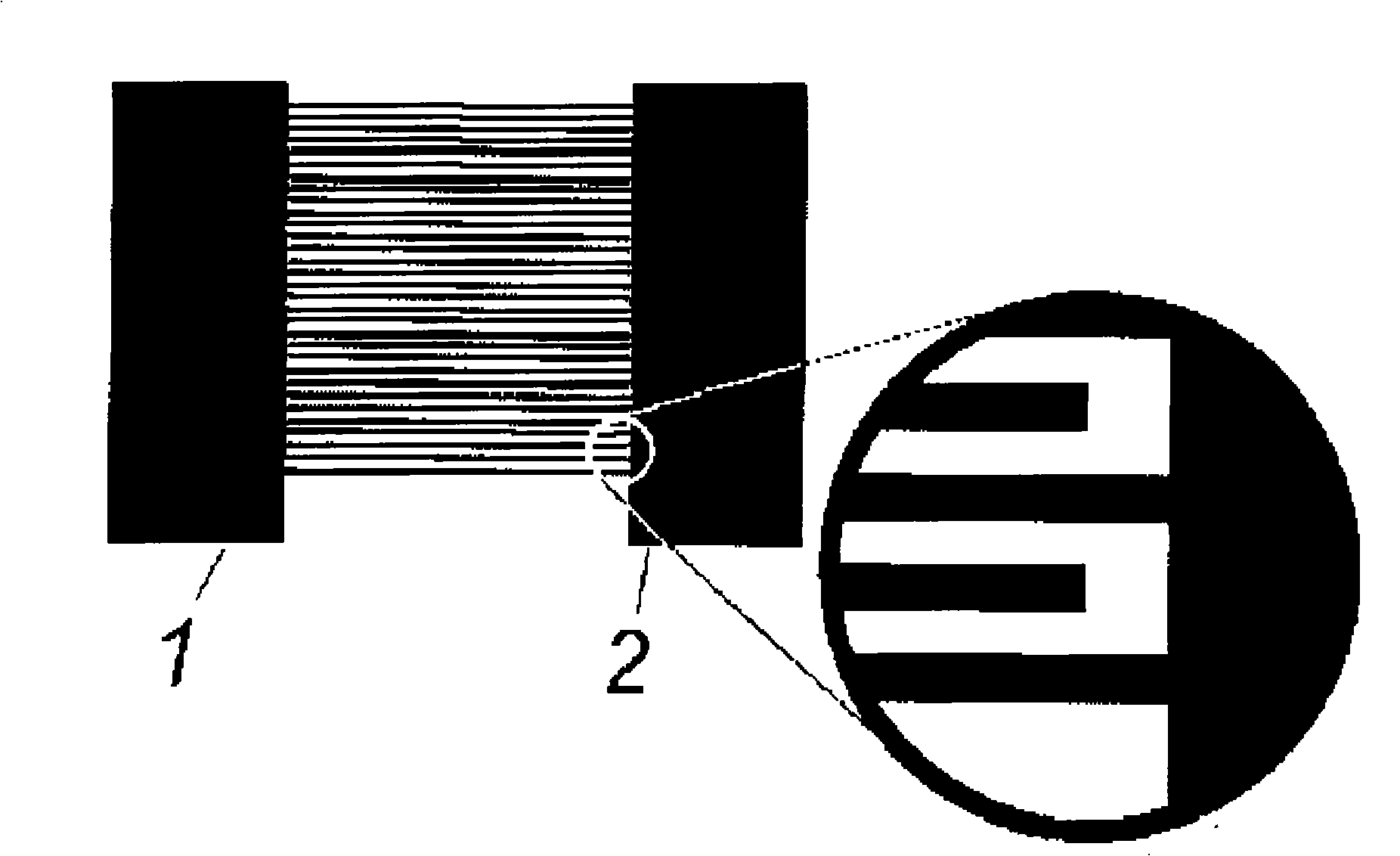

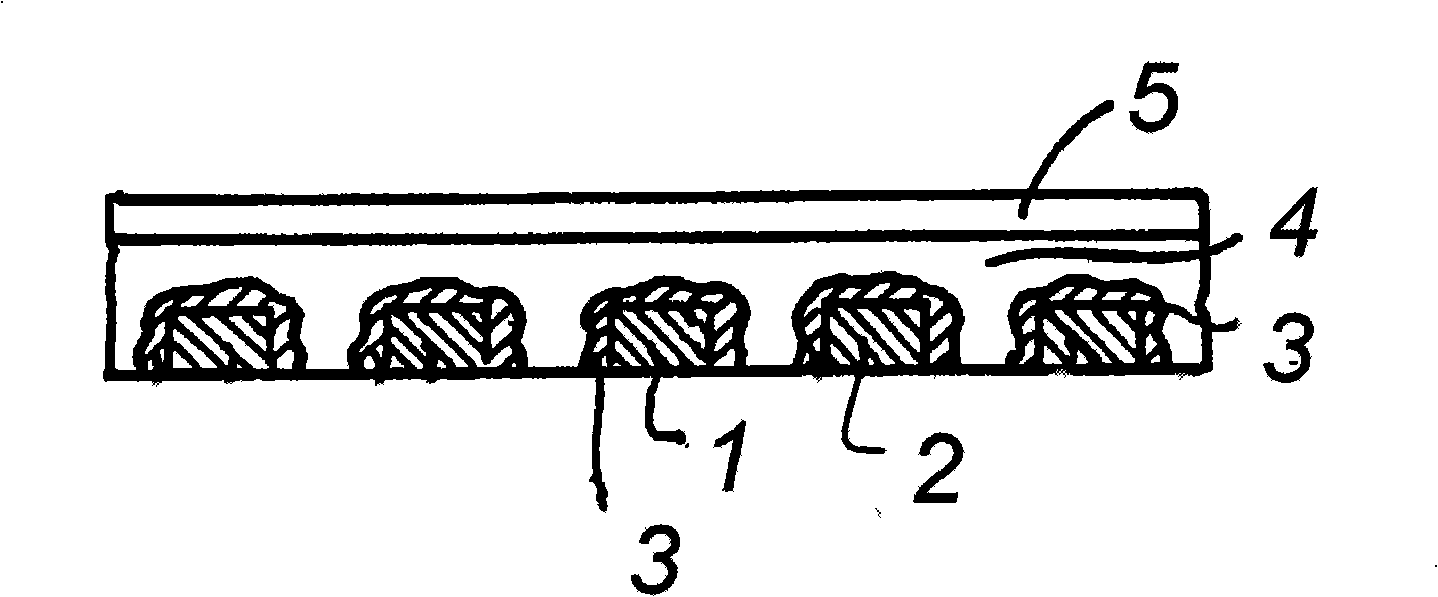

[0023] The invention proposes a polypyrrole micro-supercapacitor based on MEMS technology and a manufacturing method thereof. The micro-supercapacitor is a two-dimensional comb-tooth planar structure consisting of an anode (positive electrode) and a cathode (negative electrode) covered with the same polypyrrole active material, filled with a gel-like solid electrolyte, and then sealed in a polyimide encapsulation layer In this paper, a polypyrrole micro-supercapacitor with the characteristics of small size, high energy storage density, high discharge power, simple structure, convenient processing, and reliable performance was obtained. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] figure 1 Shown is a schematic diagram of a two-dimensional planar gold comb current collector for a micro-supercapacitor. In the figure, the comb structures of the anode gold current collector 1 and the cathode gold cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com