S-type passive micro-mixer

A mixer, passive technology, applied in mixers, laboratory utensils, chemical instruments and methods, etc., can solve the problems of poor mixing effect, shortened mixing distance, long mixing flow channel, etc., to achieve simple structure and reduce flow loss. , the effect of high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

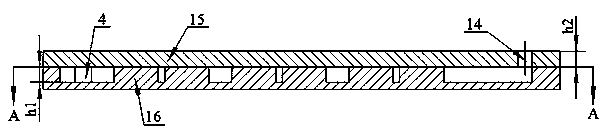

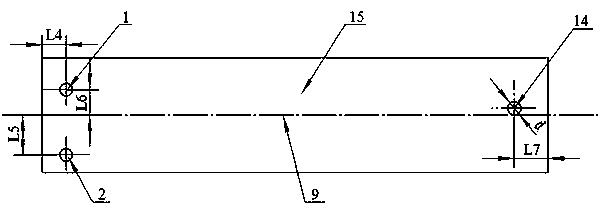

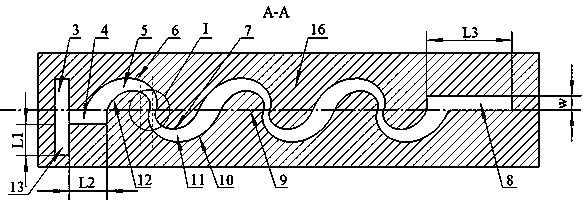

[0014] Such as Figure 1~4 As shown: the present invention includes an upper cover plate 15 and a mixing plate 16 that is positioned under the upper cover plate 15 and is bonded together with the upper cover plate 15, and the upper cover plate 15 is provided with an inlet hole one 1, an inlet hole two 2, Outlet hole 14, these three holes are all vertical through holes, all have a diameter of d, and a height of h2, which is equal to the height of the upper cover plate 15. The first inlet hole 1 and the second inlet hole 2 are located on the left side of the upper cover plate 15 , and the outlet hole 14 is located on the right side of the upper cover plate 15 . The polar axis 9 is a horizontal axis from left to right, and is the polar axis of the logarithmic helix in the mixing plate 16. The polar axis 9 is located on the vertical center plane where the upper cover plate 15 and the mixing plate 16 are located. The distance between the center of the inlet hole 1 and the inlet ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com