Method for preparing sulfone compound by utilizing electrochemical micro-channel technology

A compound and electrochemical technology, applied in the field of preparation of sulfone compounds using electrochemical microchannel synthesis technology, can solve the problems of highly toxic residues in products, high preparation costs, and engineering scale-up, and achieve fast reaction speed, high acidification degree, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

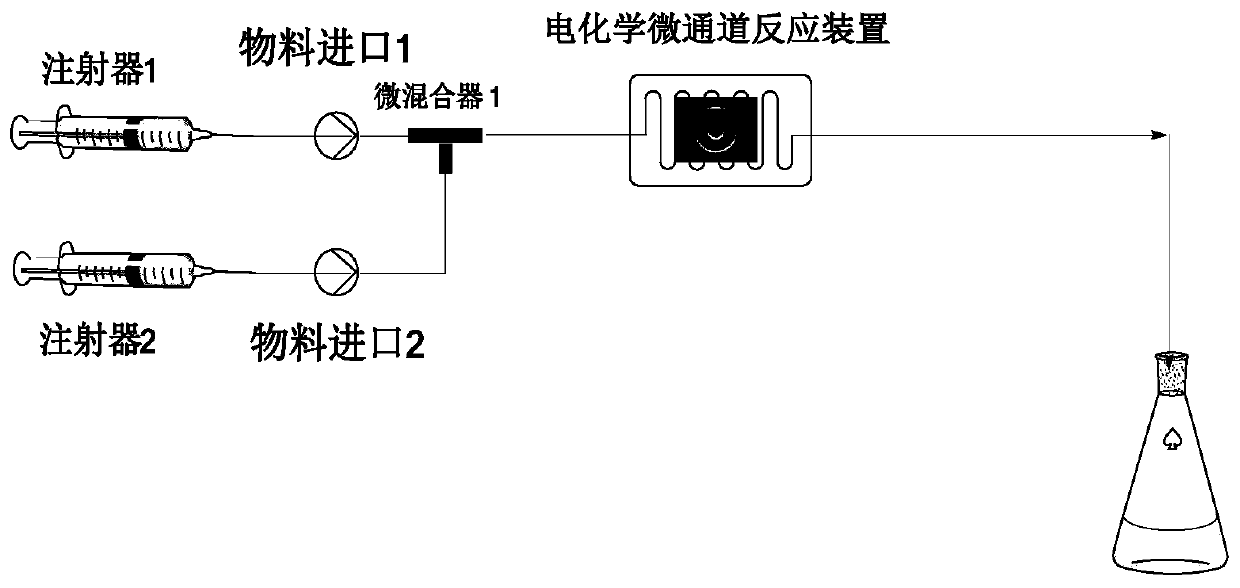

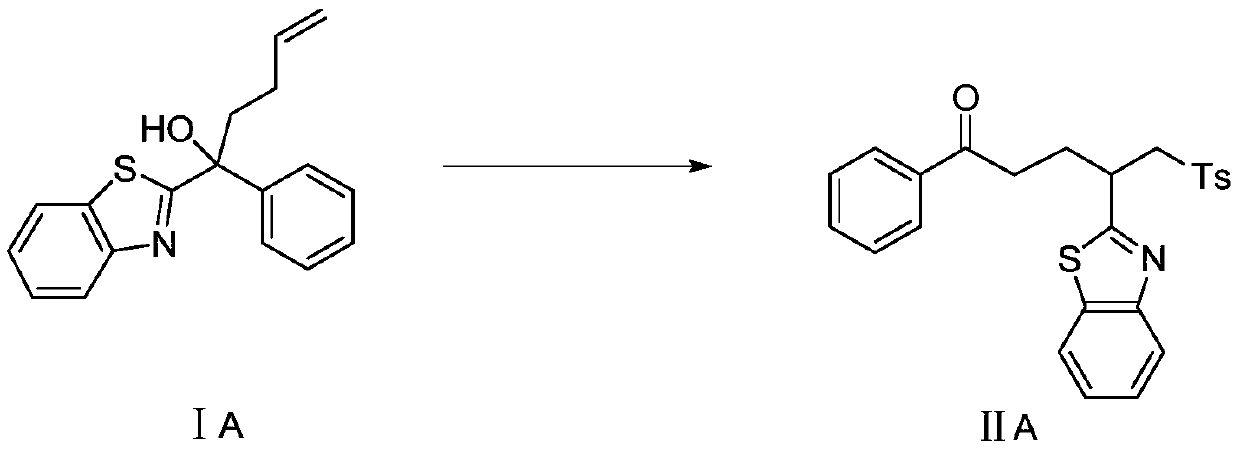

[0032]

[0033] Weigh compound IA (4mmol, 1.0equiv), with 10mL CH 3 CN / DCE (v / v=9 / 1) was dissolved and loaded into syringe 1 after complete dissolution. Weigh 4-methylbenzenesulfinic acid (12mmol, 3.0equiv), n Bu 4 NBF 4 (6.0mmol) with 10mL CH 3CN / DCE (v / v=9 / 1) was dissolved and loaded into syringe 2 after complete dissolution. After exhausting the air in the syringe, push it into the micro-mixer 1 through the syringe pump at a flow rate of 1.0mL / min. After being mixed by the mixer, pump it into the coil with an inner diameter of 0.5mm. Two graphite SK-50 electrodes are used as cathode and anode In the electrochemical microchannel reaction device, the constant current is 10mA. The reaction was carried out at room temperature with a residence time of 4 min. After the reaction was completed, it was tracked and monitored by TLC. The solution was washed with saturated NaHCO 3 The solution was quenched and the aqueous layer was washed with CH 2 Cl 2 (3 x 10 mL) extract...

Embodiment 2

[0035]

[0036] Weigh compound IA (4mmol, 1.0equiv), with 10mL CH 3 CN / DCE (v / v=9 / 1) was dissolved and loaded into syringe 1 after complete dissolution. Weigh 4-methylbenzenesulfinic acid (12mmol, 3.0equiv), n Bu 4 NBF 4 (6.0mmol) with 10mL CH 3 CN / DCE (v / v=9 / 1) was dissolved and loaded into syringe 2 after complete dissolution. After exhausting the air in the syringe, push it into the micro-mixer 1 through the syringe pump at a flow rate of 1.0mL / min. After being mixed by the mixer, pump it into the coil with an inner diameter of 0.5mm. Two graphite SK-50 electrodes are used as cathode and anode In the electrochemical microchannel reaction device, the constant current is 30mA. The reaction was carried out at room temperature with a residence time of 4 min. After the reaction was completed, it was tracked and monitored by TLC. The solution was washed with saturated NaHCO 3 The solution was quenched and the aqueous layer was washed with CH 2 Cl 2 (3 x 10 mL) extrac...

Embodiment 3

[0038]

[0039] Weigh compound IA (4mmol, 1.0equiv), with 10mL CH 3 CN / DCE (v / v=9 / 1) was dissolved and loaded into syringe 1 after complete dissolution. Weigh 4-methylbenzenesulfinic acid (12mmol, 3.0equiv), n Bu 4 NBF 4 (6.0mmol) with 10mL CH 3 CN / DCE (v / v=9 / 1) was dissolved and loaded into syringe 2 after complete dissolution. After exhausting the air in the syringe, push it into the micro-mixer 1 through the syringe pump at a flow rate of 1.0mL / min. After being mixed by the mixer, pump it into the coil with an inner diameter of 0.5mm. Two graphite SK-50 electrodes are used as cathode and anode In the electrochemical microchannel reaction device, the constant current is 1mA. The reaction was carried out at room temperature with a residence time of 4 min. After the reaction was completed, it was tracked and monitored by TLC. The solution was washed with saturated NaHCO 3 The solution was quenched and the aqueous layer was washed with CH 2 Cl 2 (3 x 10 mL) extract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com