Compound bentonite for removing fluorine from water and preparation method thereof

A technology of bentonite and calcium-based bentonite, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve the problems of high price, bentonite content not higher than 70%, low adsorption performance, etc., and achieve low production cost , less synthetic steps, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step, the preparation of purified calcium-based bentonite

[0028] Add commercially available calcium-based bentonite mineral powder and tap water at a mass ratio of 1:6-7, stir for 20-40 minutes, let stand for 20-30 hours, then stir for 10-20 minutes, then add tap water or repeat the preparation. The supernatant taken out during the first preparation is prepared into a mass ratio of calcium-based bentonite slag: water=1: 9~11 feed liquid, continue to stir for 9~11 minutes, then let stand to settle for 3~5 hours, and take out the supernatant The liquid is then used for the next preparation of the feed liquid, and the upper layer of fine soil is taken out from the sediment, and the fine soil is dried in an oven at 100°C until the quality of the fine soil remains unchanged, then crushed, and passed through a 200-mesh sieve. Purified calcium-based bentonite;

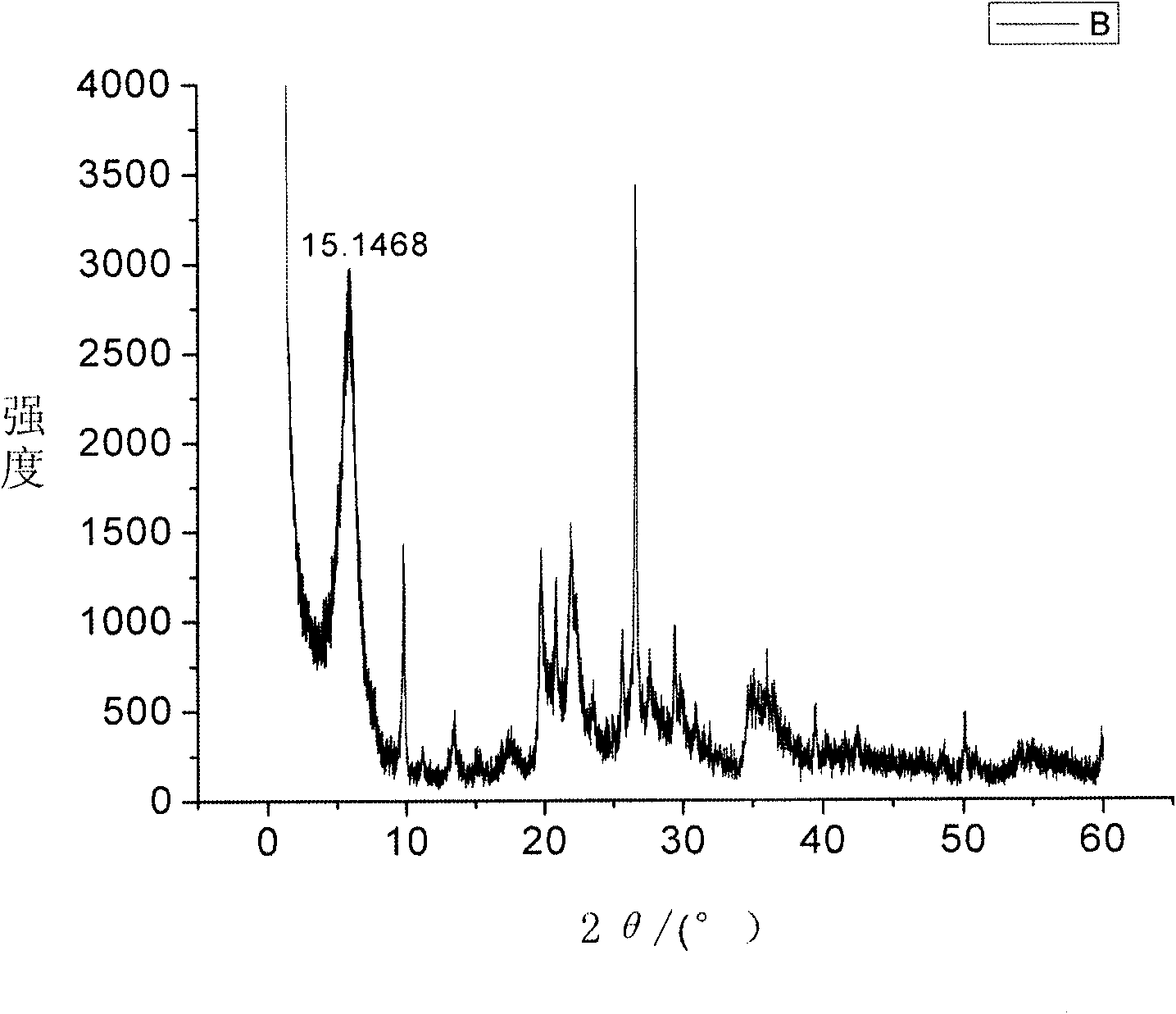

[0029] figure 1In order to purify the X-ray fluorescence diffraction pattern of calcium-based bentonit...

Embodiment 2

[0037] The first step, the preparation of purified calcium-based bentonite

[0038] With the first step of embodiment 1;

[0039] The second step, solution polymerization

[0040] Weigh 8.00 g of the purified calcium-based bentonite obtained in the first step and 2.00 g of commercially available monomeric acrylamide, mix them and dissolve them in 25 mL of deionized water to prepare a mixed solution, stir at room temperature for 1 hour, mix well and then heat up to 70°C, then add 0.0096g initiator azobisisobutyronitrile and 0.50g crosslinking agent formaldehyde solution, continue to stir until the solution gradually becomes viscous and polymerizes and solidifies, and the reaction is completed, then maintain a constant temperature of 70°C, from The reaction time of reaction cessation is 2 hours, and the obtained wet solid phase product;

[0041] The third step is vacuum drying to obtain a composite bentonite product for removing fluorine from water

[0042] The wet solid phas...

Embodiment 3

[0045] The first step, the preparation of purified calcium-based bentonite

[0046] With the first step of embodiment 1;

[0047] The second step, solution polymerization

[0048] Weigh 9.00 g of the purified calcium-based bentonite obtained in the first step and 1.00 g of commercially available monomeric acrylamide, mix and dissolve in 25 mL of deionized water to prepare a mixed solution, stir at room temperature for 1 hour, mix well and then heat up to 70°C, then add 0.0096g initiator azobisisobutyronitrile and 0.50g crosslinking agent formaldehyde solution, continue to stir until the solution gradually becomes viscous and polymerizes and solidifies, and the reaction is completed, then maintain a constant temperature of 70°C, from The reaction time of reaction stop is 2.5 hours, the wet solid phase product that makes;

[0049] The third step is vacuum drying to obtain a composite bentonite product for removing fluorine from water

[0050] The wet solid phase product obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com