Aerobic granular sludge with strengthened inner core and strengthened framework, and culture method thereof

A technology of aerobic granular sludge and cultivation method, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of unstable aerobic granular sludge, etc. To achieve the effect of short culture period, strong stability and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

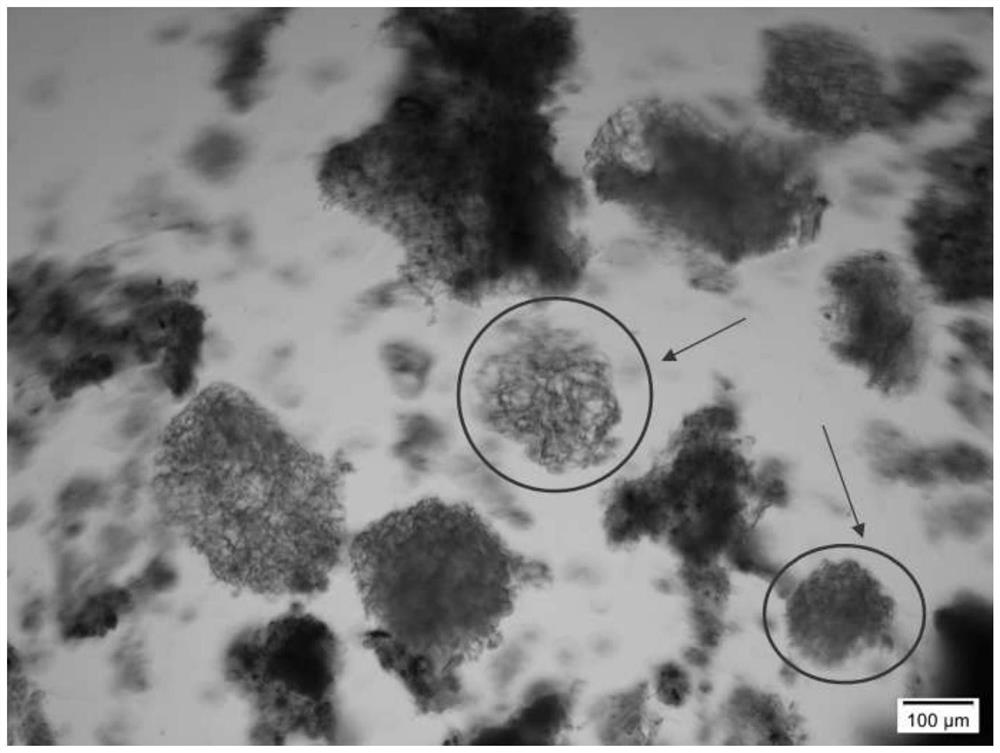

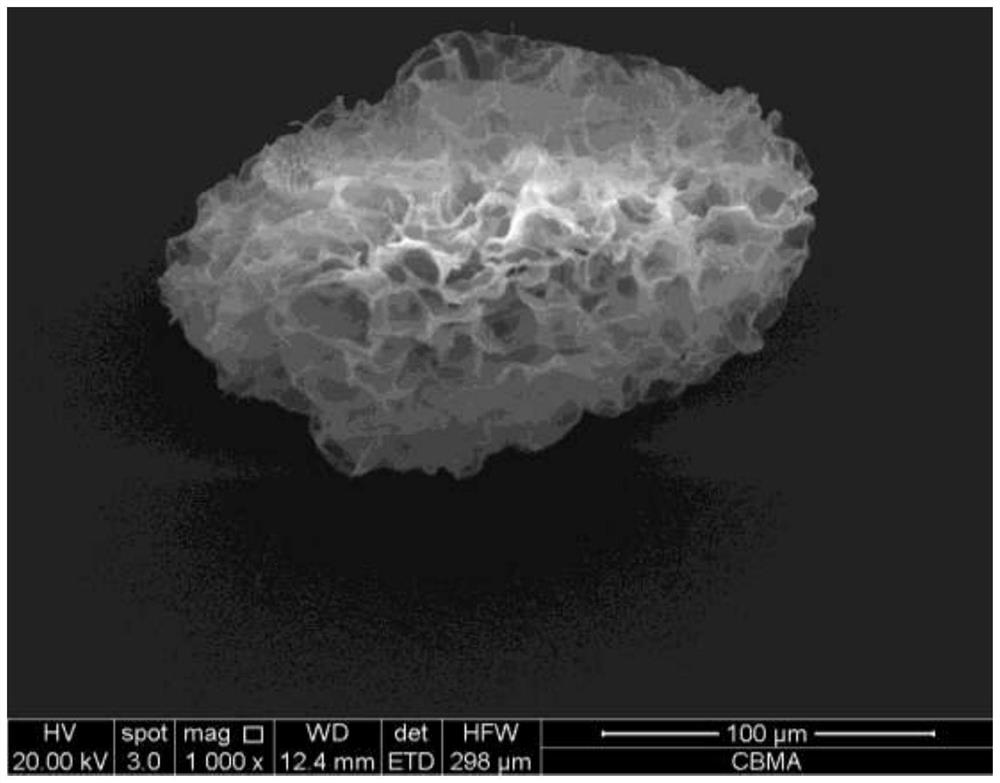

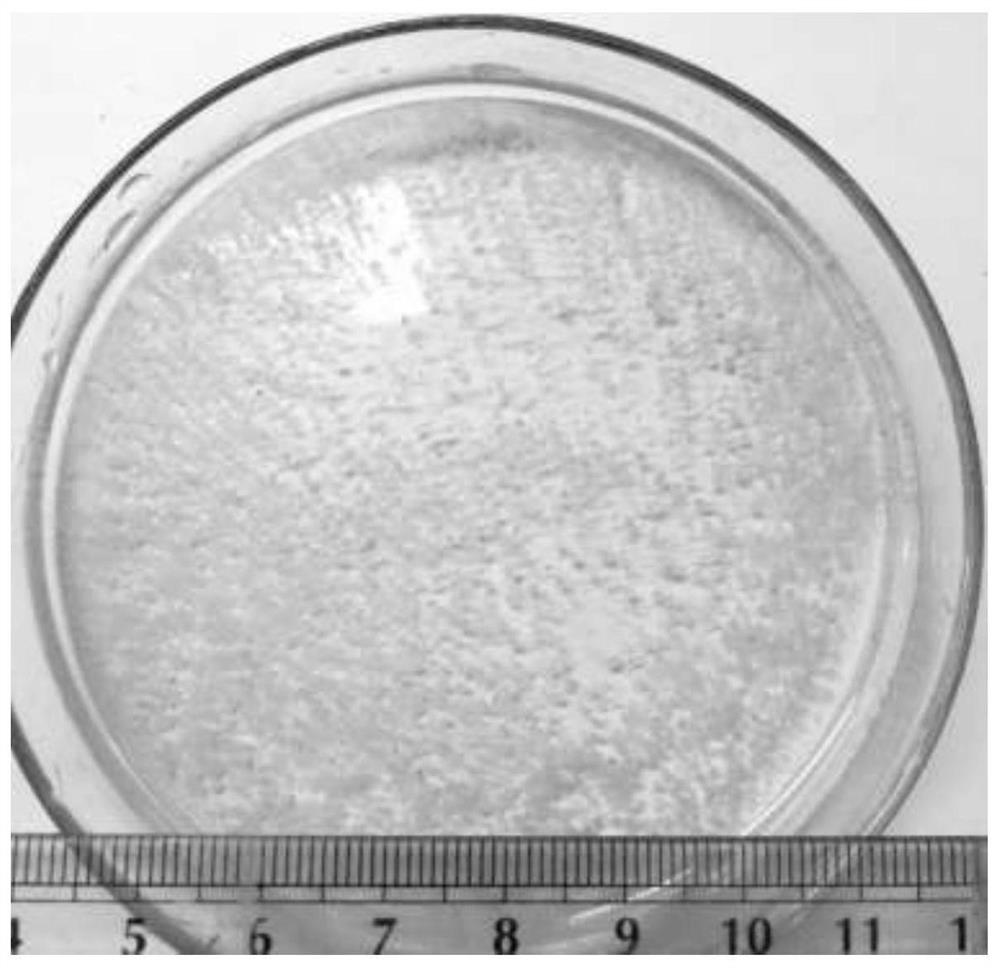

Embodiment 1

[0026] Inoculate 5,400 mg / L of activated sludge and 200,000 microcarriers / L in the reactor (height-to-diameter ratio: 10:1), control the reaction temperature at 25°C, pH=7.5-8.5, and the surface air velocity in the aeration stage is 0.8cm / s, DO≥4.0mg / L. The batch instruction cycle is 6 hours, including water inflow for 5 minutes, anaerobic stirring for 2 hours, aeration for 2 hours, anoxic stirring for 1 hour 20 minutes to 1 hour 47 minutes, precipitation for 30 minutes to 3 minutes, drainage and idle time for 5 minutes. Artificially prepared municipal sewage (ammonia nitrogen 60-70mg / L, TP 4-6mg / L, COD 250-320mg / L) was used for cultivation. On the 25th day, the granular sludge with a particle size greater than 200um in the reactor Occupying the main body of the reactor, the particle size is between 0.6 and 1.0 mm, and has good sedimentation properties. The removal rates of COD and ammonia nitrogen are above 90%, and the removal rates of total nitrogen are above 75%.

Embodiment 2

[0028] Inoculate 4000mg / L of activated sludge and 250,000 microcarriers / L in the reactor (height-to-diameter ratio: 10:1), control the reaction temperature at 25°C, surface gas velocity at 1.0cm / s, DO≥4.0mg / L , pH=7.5~8.5. The ordering period is 8 hours, including water inflow for 5 minutes, anaerobic stirring for 2 hours, aeration for 2.5 hours, anoxic stirring for 2 hours 50 minutes to 3 hours 17 minutes, precipitation for 30 minutes to 3 minutes, drainage and idle time for 5 minutes. Artificially prepared municipal sewage (ammonia nitrogen 60-70mg / L, TP 4-6mg / L, COD 250-320mg / L) was used for cultivation. On the 27th day, the granular sludge with a particle size greater than 200um in the reactor Occupying the main body of the reactor, the particle size is between 0.5 and 1.7 mm, and has good sedimentation properties. The removal rates of COD and ammonia nitrogen are above 90%, and the removal rates of total nitrogen are above 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com