Anisotropic flow shallow layer rotary sedimentation tank

A rotary and sedimentation tank technology, which is applied in the direction of sedimentation separation, sedimentation tank, feeding/discharging device of the sedimentation tank, etc., can solve the problem of affecting the effective settlement of suspended solids, low space utilization of the sedimentation tank, and reduced sedimentation space of the sedimentation tank and other problems, to achieve good settling performance, convenient collection and discharge, and improve the effect of settling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

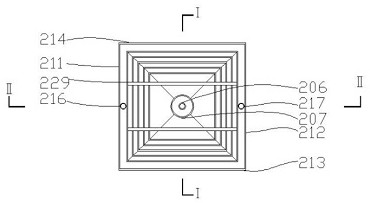

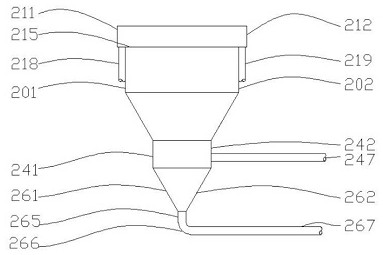

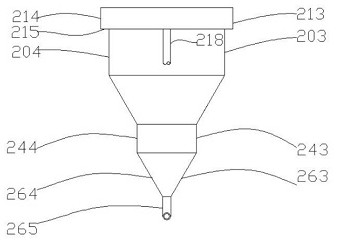

[0027] The following are specific embodiments of the present invention and in conjunction with the attached figure 1 ~ attached Figure 8 , to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0028] A kind of reverse flow shallow rotary sedimentation tank, including the upper water inlet area 20, the outer drainage tank 21, the middle sedimentation area 22, the lower buffer zone 24, the bottom mud collection area 26, the vertical The centerlines coincide.

[0029] The water inlet area 20 includes a left wall panel 201 , a right wall panel 202 , a front wall panel 203 , a rear wall panel 204 , a water outlet hole 205 , a water inlet vertical pipe 206 , and a water inlet bell mouth 207 . The left wall plate 201, the right wall plate 202, the front wall plate 203 and the rear wall plate 204 are all rectangular thin plates with the same size. The vertical sides of the left wall plate 201 , the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com