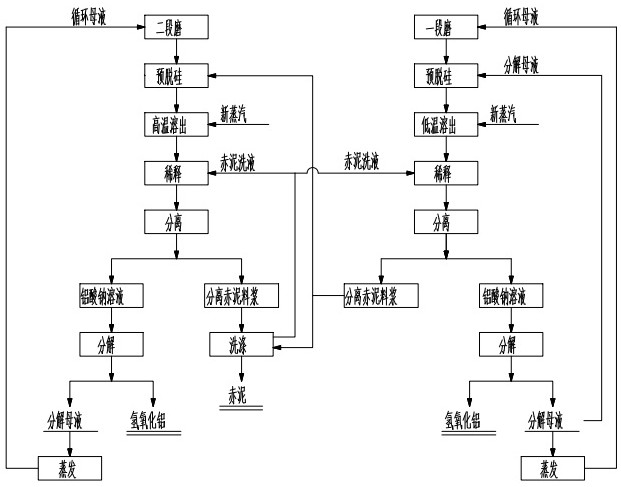

Production process for combining high-temperature dissolution and low-temperature dissolution of multiple bauxite sources

A production process and high-temperature dissolution technology, which is applied to the preparation of aluminum compounds, alkali metal aluminates/aluminum oxide/aluminum hydroxide, inorganic chemistry, etc., can solve the problems of low comprehensive energy consumption, low investment and operation costs, and achieve Low overall energy consumption, low investment and operating costs, and good settlement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The ores used by the production organization of an alumina factory in China mainly include domestic ore (diaspore type), Guinea ore (low silicon gibbsite type) and Indonesian ore (high silicon gibbsite type). Domestic mines must adopt high-temperature dissolution process, Guinea mines can adopt high-temperature dissolution process or low-temperature dissolution process, and Indonesian mines must adopt low-temperature dissolution process. Using the patent of the invention, it is convenient to deal with the change of ore source in production.

[0031] Production organization plan 1: When the ore sources are only domestic mines and Guinea mines, the domestic mines go from the second-stage grinding process to the high-temperature dissolution process, and the Guinea mines follow the first-stage grinding process to the low-temperature dissolution process. Because the aluminum-silicon ratio of red mud dissolved in Guinea mine at low temperature is as high as about 3.5, the ore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com