Method for producing passive micro-mixer and micro-reactor in micro-flow control chip

A microfluidic chip and micro-mixer technology, which is applied in semiconductor/solid-state device manufacturing, instruments, material inspection products, etc., can solve the problems of high requirements for equipment and materials, complex process, etc., and achieve low cost of substrates, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

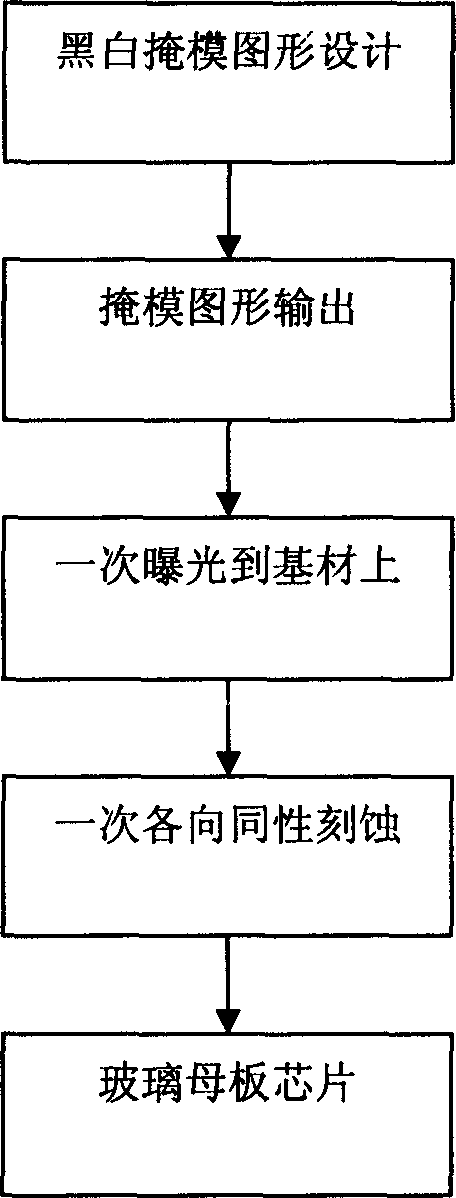

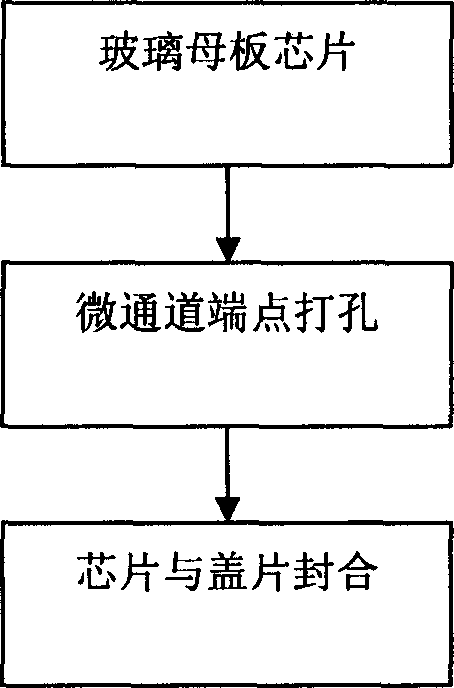

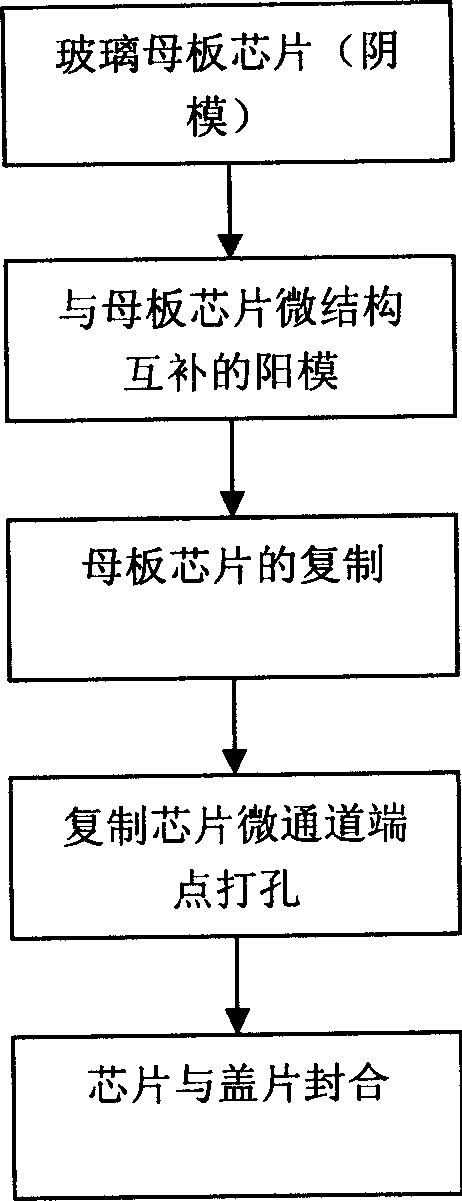

[0017] Figure 5 Demonstrates the fabrication process of a Y-shaped micromixer mother glass. The mixer has two material introduction channels, and the main mixing channel has a fishbone submicrostructure. The mask is printed onto polyester film with a laser imagesetter with a resolution of 3000dpi. Commercialized glass substrate with chromium layer and AZ1805 positive photoresist (Changsha Shaoguang Microelectronics Corporation SG2506 type, chrome plate thickness 145nm, glue thickness 550nm), using 100W high-pressure mercury lamp ultraviolet light source, using JKG-2A photolithography machine Type (Shanghai Xueze Optical Machinery Co., Ltd.) exposure for 30 seconds. Shake gently in 0.5% NaOH for 45 seconds, and after 20 minutes in an oven at 110°C, in a chrome-removing solution (70% HClO 4 104ml+(NH 4 ) 2 Ce(NO 3 ) 6 400g+1760ml H 2 O) shake for 2 minutes to remove the exposed chromium protective layer. With 1:2:7 volume ratio of HF-HNO 3 -H 2 O etchant water bath ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com