Water pump with filter screen limiting system

A filter and water pump technology, which is applied to parts, pumps, and pump components of elastic fluid pumping devices, can solve problems such as inconvenient use, easy rotation or offset of the filter, and achieve the effect of accelerating circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

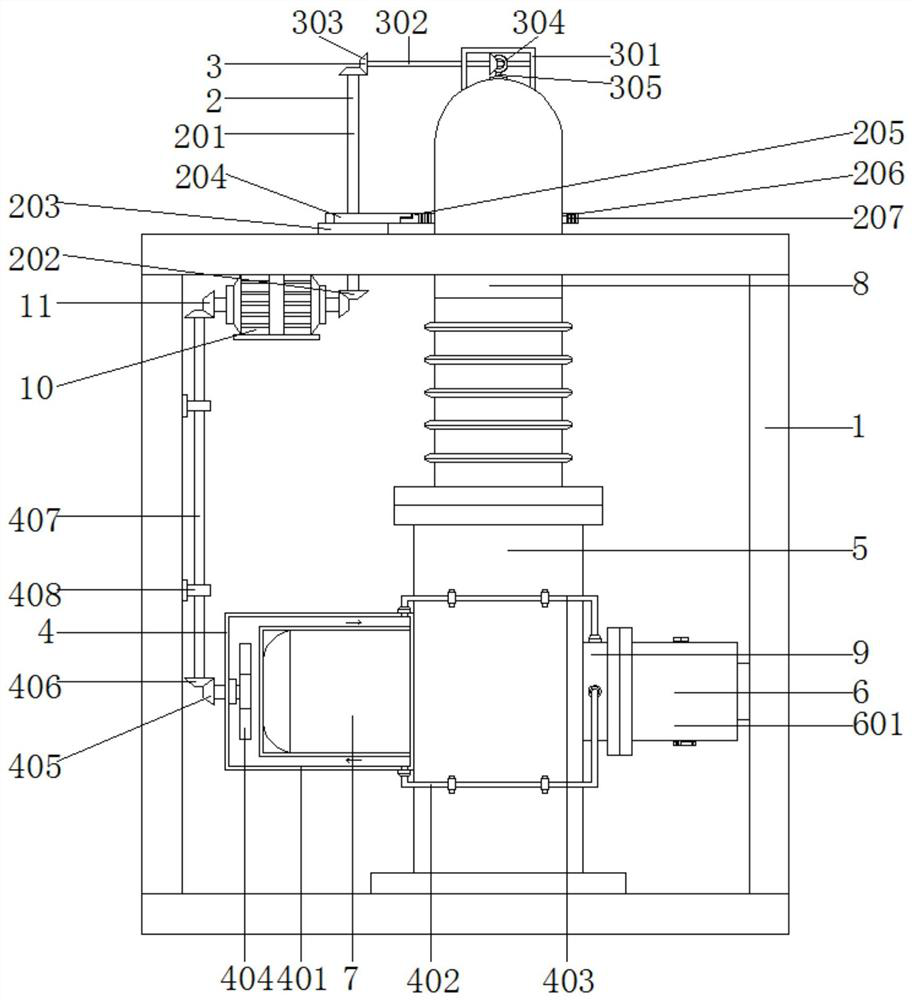

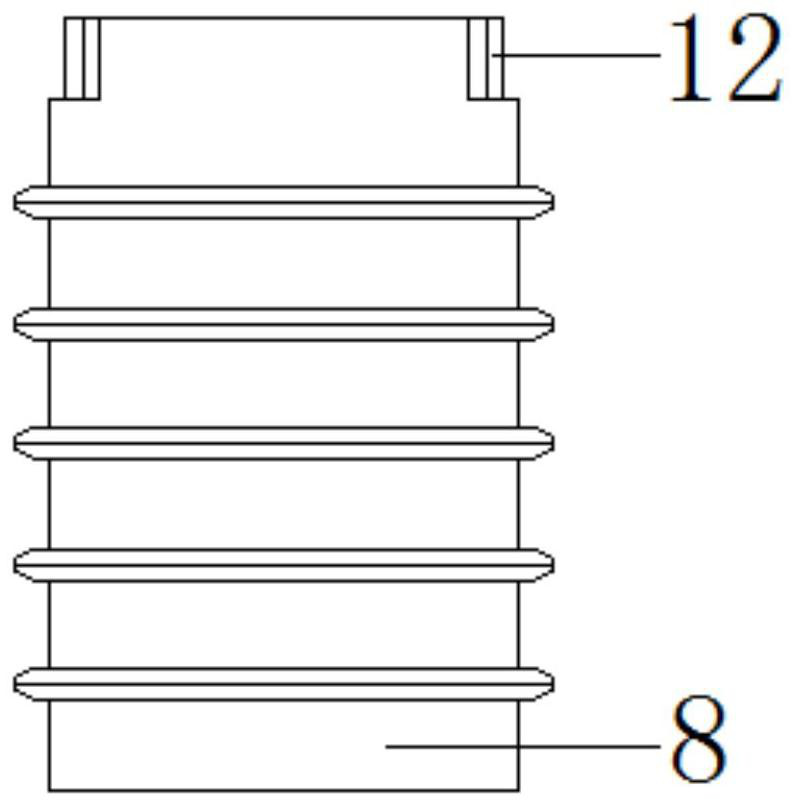

[0044] see Figure 1-7 , a water pump with a filter restricting system, comprising a frame 1 and a pump main body 5, the water pump main body 5 is fixedly connected above the bottom of the frame 1, a drive motor 7 is installed on one side of the water pump main body 5, and a connection is installed on the other side Pipeline 9, the top of water pump main body 5 is provided with drainpipe 8, and the bottom end of drainpipe 8 passes the top of frame 1, and is provided with sealed bearing 12 between the bottom end and the top of water pump main body 5; Sealed bearing 12 is to realize Rotary connection between the drain pipe 8 and the water pump main body 5 .

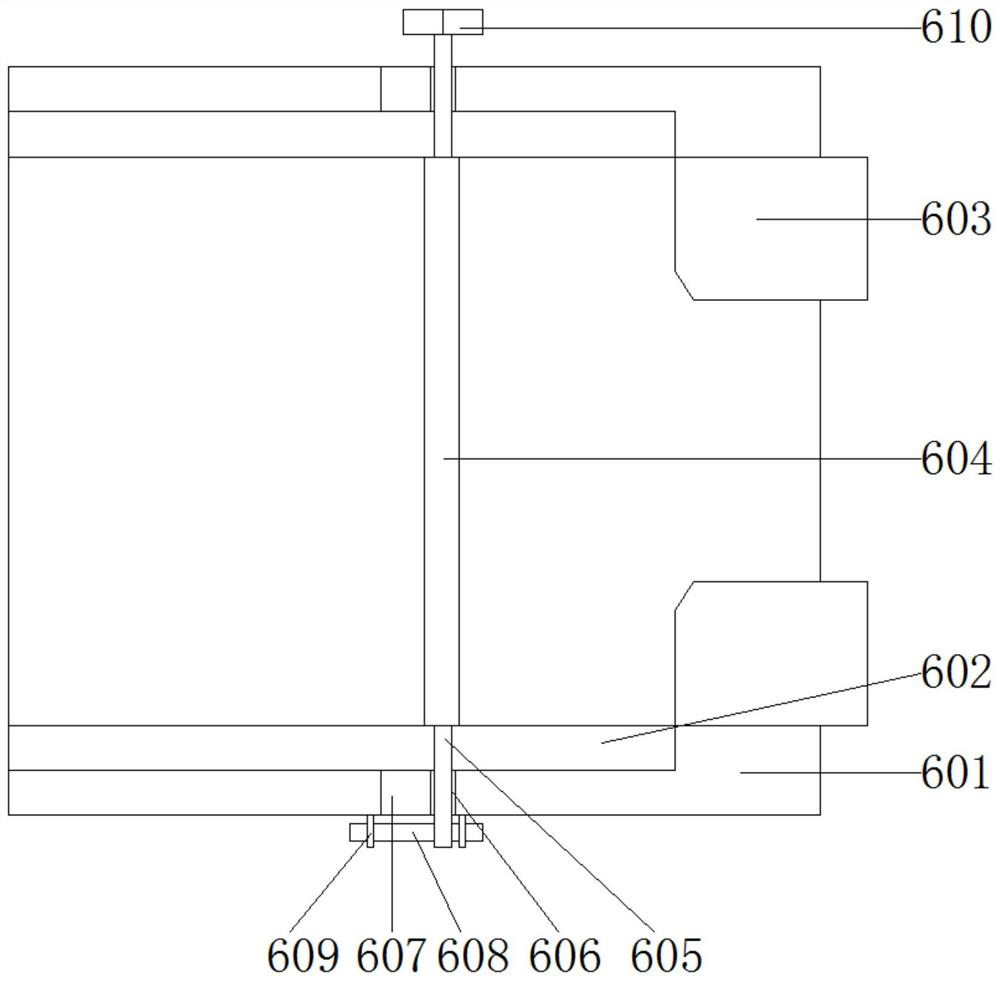

[0045] One side of the connecting pipe 9 is provided with a restricting mechanism 6, which includes a filter pipe 601, a moving pipe 602, a limit ring pipe 603, a filter screen 604, a rotating rod 605, a limit sleeve 606, a rectangular groove 607, and an adjustment rod 608 , fixed plate 609, adjustment handle 610 and isola...

Embodiment 2

[0048] see figure 1 , 8 , 9 and Figure 12 , one side of the drain pipe 8 is provided with a first adjustment mechanism 2, the first adjustment mechanism 2 includes a first transmission rod 201, a first bevel tooth 202, a first gear 203, a movable rod 204, a moving plate 205, a semicircular tooth Patterned plate 206, rectangular toothed plate 207, slide plate 208, clip bar 209 and second gear 210; one side of drain pipe 8 is fixedly connected with semicircular toothed plate 206, and one side tooth of semicircular toothed plate 206 A rectangular toothed plate 207 is connected together, a moving plate 205 is arranged on one side of the rectangular toothed plate 207, a sliding plate 208 is arranged on one side of the moving plate 205, the sliding plate 208 is fixedly connected to the top of the frame 1, and one end of the sliding plate 208 is provided with a movable Rod 204, one end of the movable rod 204 is provided with a first gear 203, the first gear 203 is rotatably connec...

Embodiment 3

[0052] see figure 1 , 8 , 10 and Figure 12 , the top of the drain pipe 8 is provided with a second adjustment mechanism 3, the second adjustment mechanism 3 includes a concave plate frame 301, a second transmission rod 302, a second bevel tooth 303, a third bevel tooth 304, a support rod 305, a curved rod 306, connecting rod 307 and blocking sheet 308; the top of the drain pipe 8 is provided with a concave plate frame 301, the inside of the concave plate frame 301 is provided with a second transmission rod 302, and the two ends of the second transmission rod 302 are provided with a second Bevel teeth 303, one side of a set of second bevel teeth 303 is engaged with third bevel teeth 304, one side of the third bevel teeth 304 is provided with a curved rod 306, and the two ends of the curved rod 306 are provided with support rods 305, And the middle end is provided with a connecting rod 307 , one end of the connecting rod 307 is provided with a blocking piece 308 , and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com